Feeding and discharging device for centerless grinding machine for performing plunge-cut grinding on bearing rollers

A technology of cutting into grinding and bearing rollers, which is applied in the direction of grinding machines, grinding feed movement, grinding/polishing equipment, etc., and can solve problems such as slow loading and unloading speed, inability to completely remove scratches from rollers, and appearance quality problems , to avoid bruising, simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific drawings and embodiments.

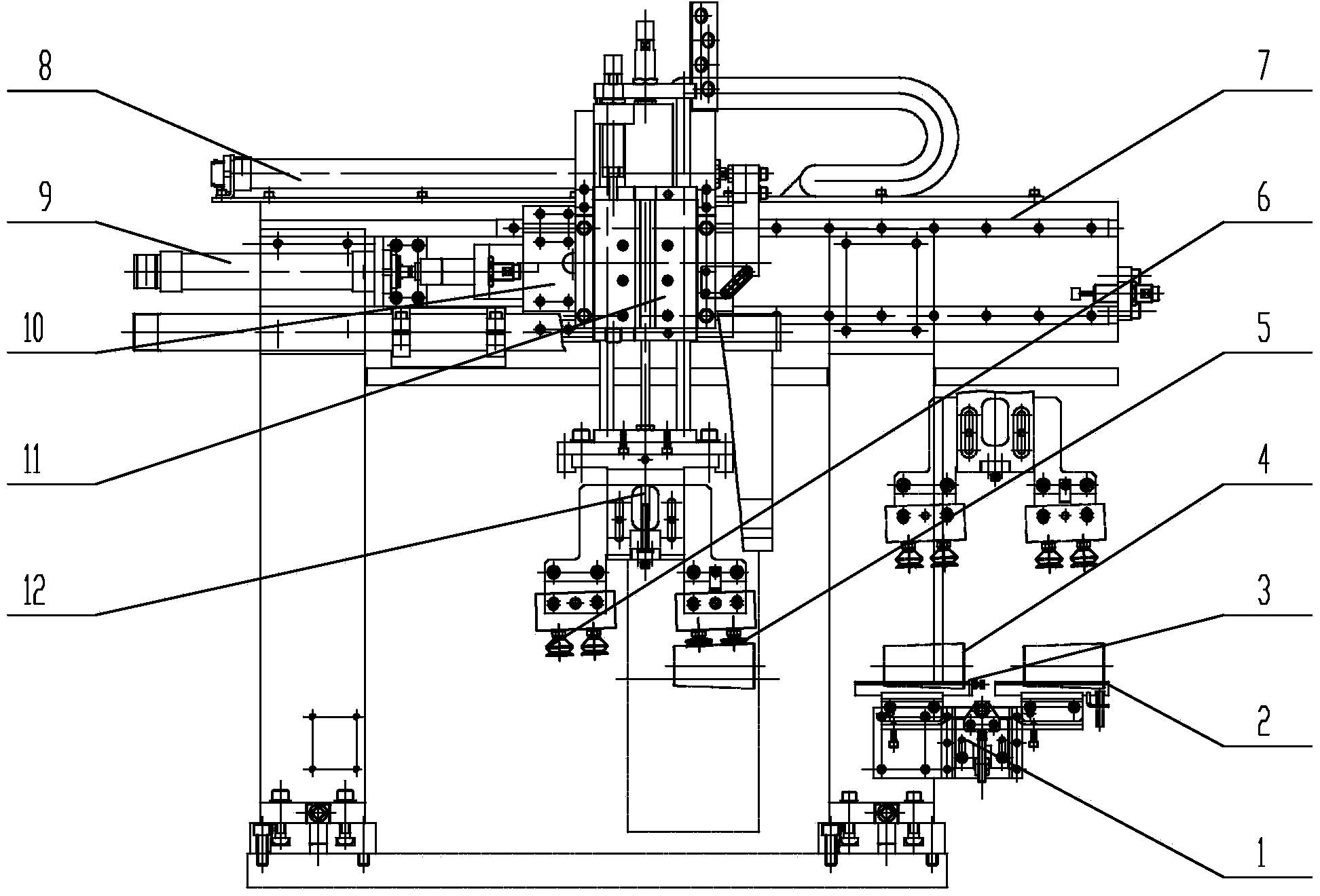

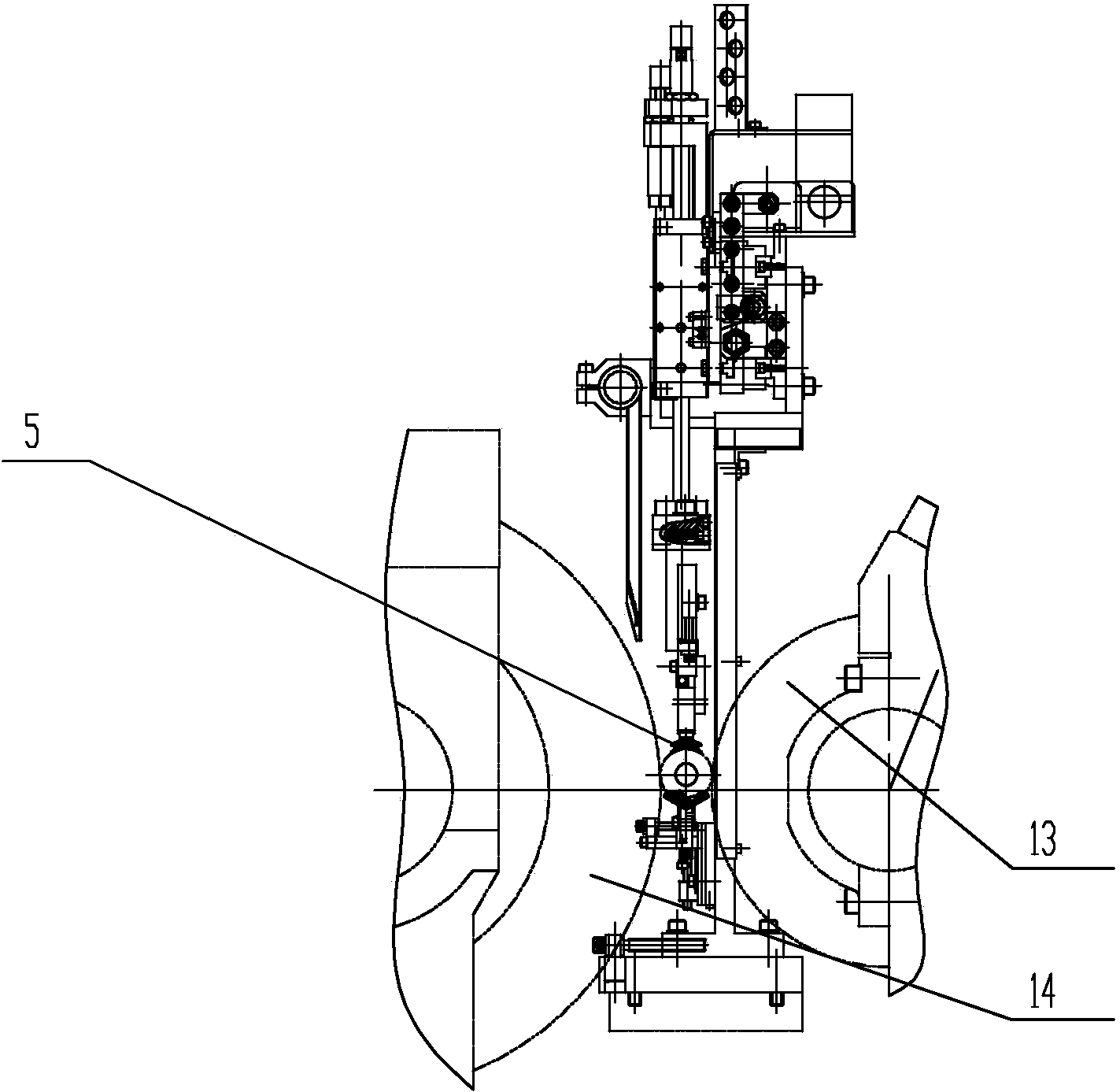

[0011] Such as figure 1 , figure 2 As shown, it includes material rack 1, blanking V-shaped groove 2, loading V-shaped groove 3, tapered roller 4, blanking suction cup 5, loading suction cup 6, guide rail 7, first cylinder 8, second cylinder 9, Skateboard 10, guide cylinder 11, mechanical arm 12, guide wheel 13, grinding wheel 14 etc.

[0012] Such as figure 1 , figure 2 As shown, a centerless grinding machine of the present invention cuts into the grinding bearing roller loading and unloading device, including a grinding frame. Move left and right; the first cylinder 8 for controlling the left and right movement of the slide plate 10 is arranged on the top of the grinding frame, specifically, the piston rod of the first cylinder 8 is connected to the slide plate 10, so that the first cylinder 8 and the slide plate 10 can be realized. There is also a gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com