Centerless grinding apparatus and centerless grinding process

一种无心磨削、磨削的技术,应用在磨削/抛光设备、为磨削工件旋转面设计的机床、金属加工设备等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be described with reference to the drawings.

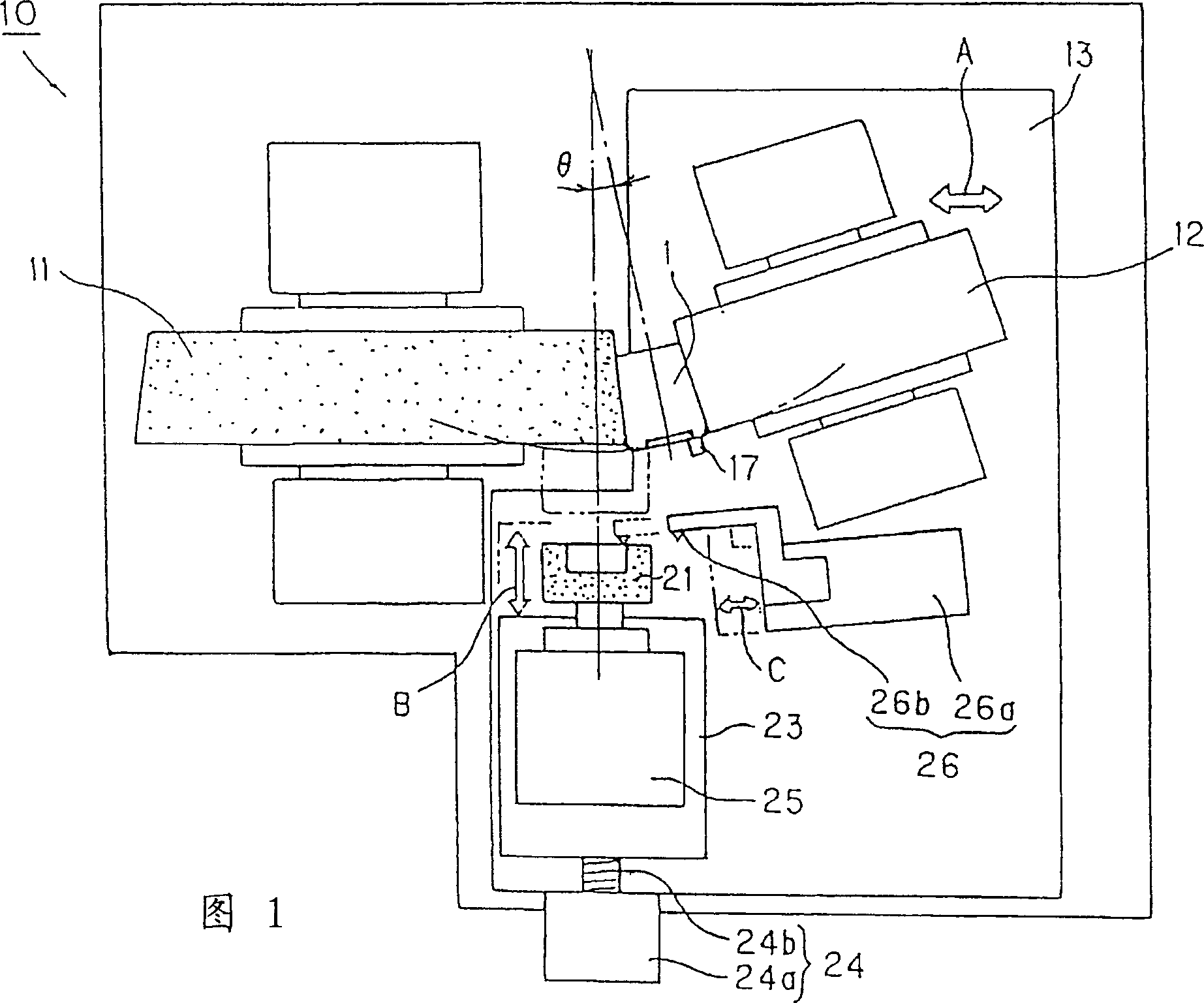

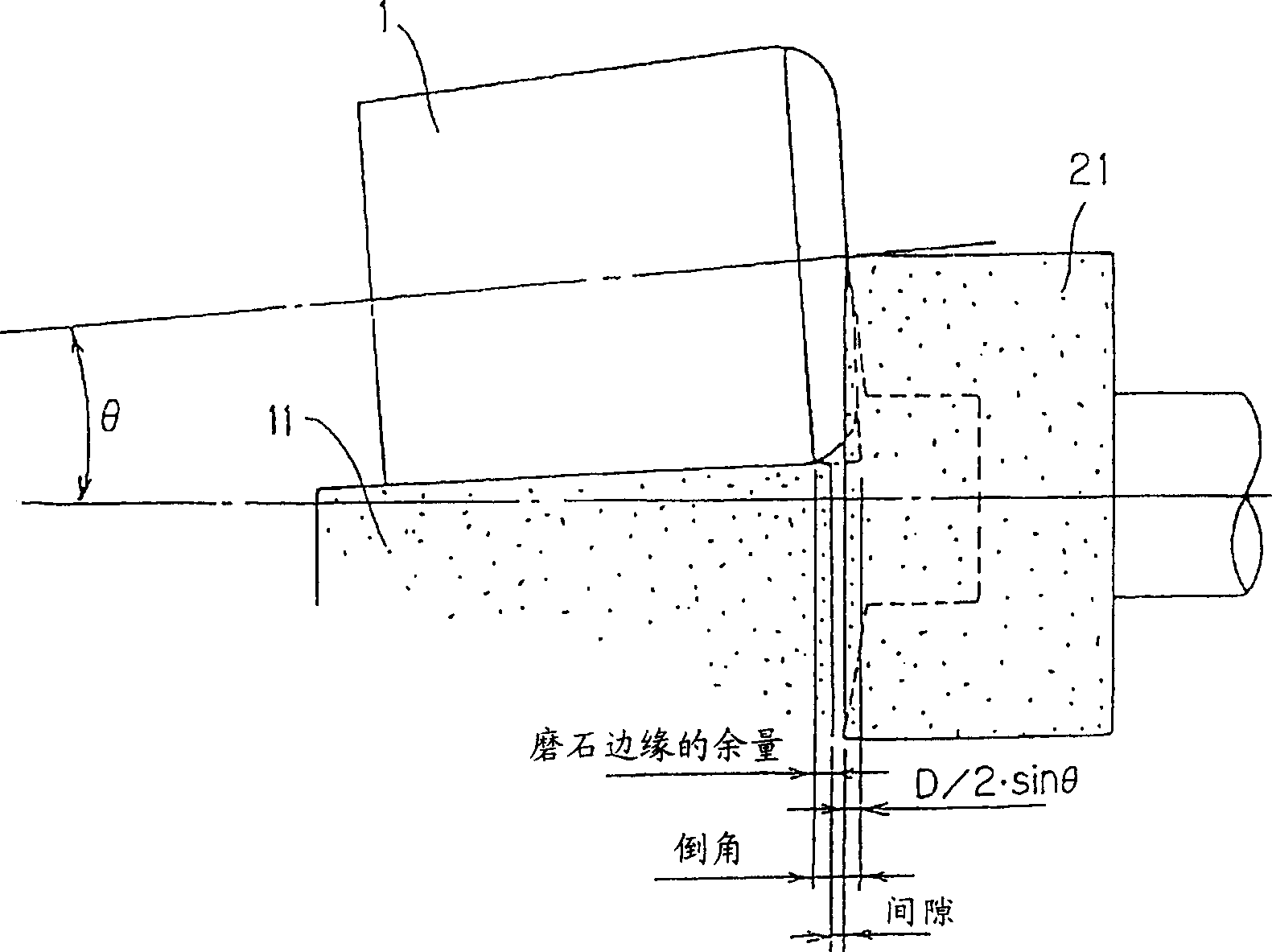

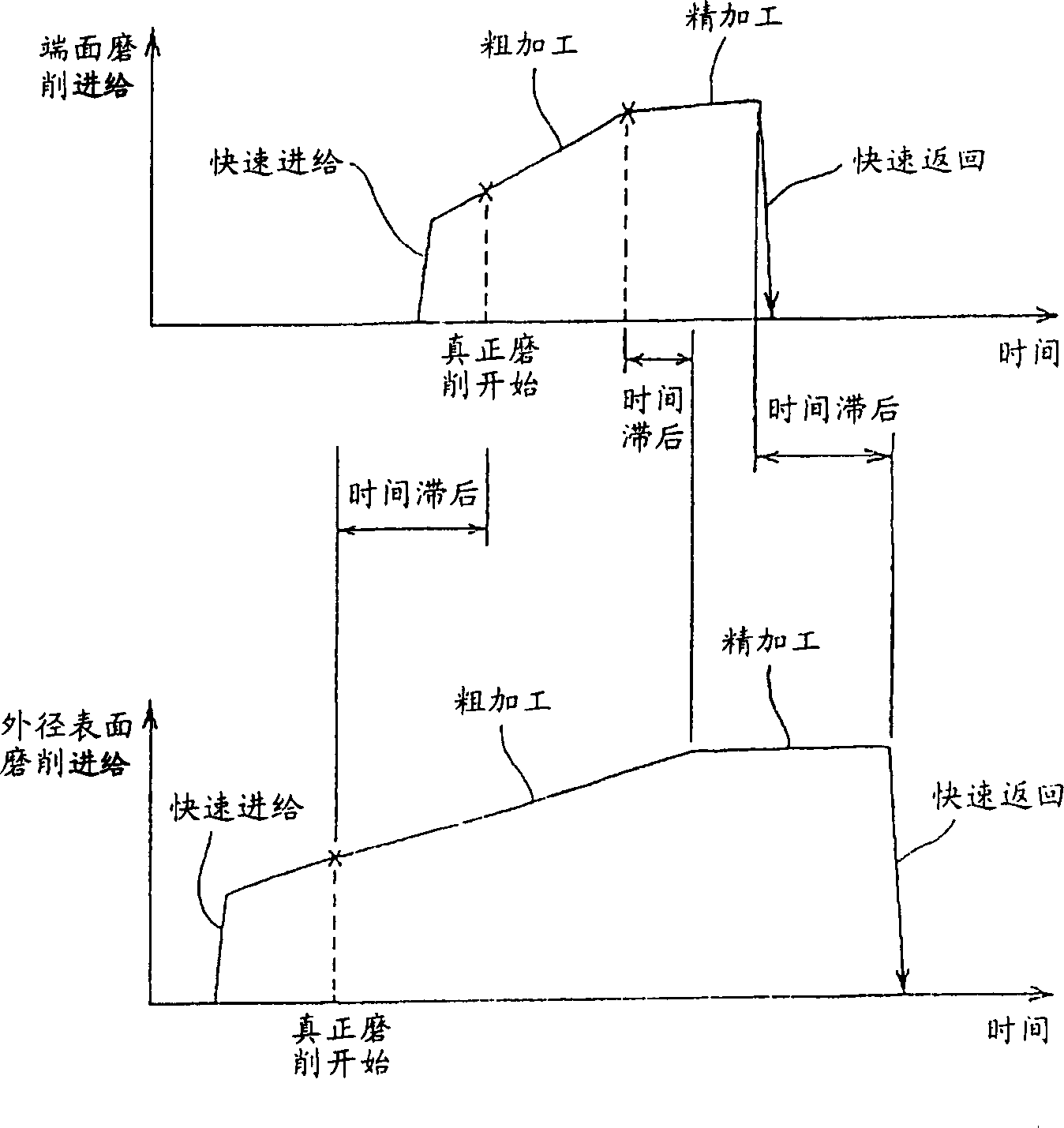

[0035] Fig. 1 is a schematic plan view of a centerless grinding apparatus 10 according to a first embodiment of the present invention. The centerless grinding apparatus 10 is suitable for grinding a workpiece such as a tapered roller 1 or the like. The first grinding mechanism for grinding the outer diameter surface of the workpiece 1 includes an outer diameter surface grinding wheel 11 formed in a disk shape, an adjustment wheel 12, and a device for respectively moving the adjustment wheel 12 closer to the outer diameter surface grinding wheel 11 and from the outer diameter surface. Outer diameter surface cutting table 13 separated from surface grinding wheel 12, supporting blade for supporting workpiece 1 from the lower side of the workpiece (supporting workpiece 1 from the rear of the figure), and dressing device for outer diameter surface grinding wheel 11 and adjustment wheel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com