Assembly method of timing chain

An assembly method and chain technology, applied in the direction of metal chains, etc., can solve the problems of difficult operation, low assembly efficiency, misoperation, etc., and achieve the effect of reducing initial elongation and improving fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

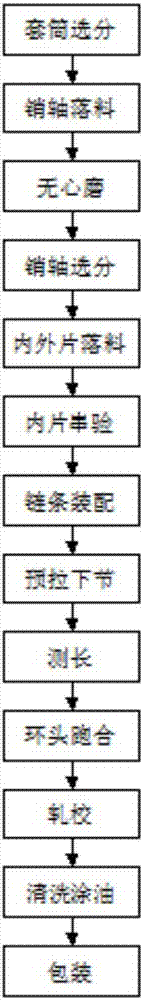

[0059] A method for assembling a timing chain, comprising the following steps: sleeve selection, pin blanking, centerless grinding, pin selection, inner and outer plate blanking, inner plate string inspection, chain assembly, pre-drawing the lower joint, measuring Length, ring head run-in, rolling, cleaning, oiling and packaging, the assembly method of the timing chain, the specific steps are as follows:

[0060] S1: Socket sorting: Pour the socket into the string inspection box, string it into the hand fork, and then visually select it to pick out cracks, large gaps, spots, pitting, rust, hard marks, and crooked sockets Unqualified products with defects on the surface are reserved;

[0061] S2: Pin shaft blanking: The operator manually changes the 70KG large roll of pin shaft wire into a 20KG small roll of pin shaft wire and places it on the material rack of the pin shaft blanking machine, and pinches off the wire by 5mm with a hand vise , and then use a small assorted file ...

Embodiment 2

[0102] A method for assembling a timing chain, comprising the following steps: sleeve selection, pin blanking, centerless grinding, pin selection, inner and outer plate blanking, inner plate string inspection, chain assembly, pre-drawing the lower joint, measuring Length, ring head run-in, rolling, cleaning, oiling and packaging, the assembly method of the timing chain, the specific steps are as follows:

[0103] S1: Socket sorting: Pour the socket into the string inspection box, string it into the hand fork, and then visually select it to pick out cracks, large gaps, spots, pitting, rust, hard marks, and crooked sockets Unqualified products with defects on the surface are reserved;

[0104] S2: Pin shaft blanking: The operator manually changes the 90KG large roll of pin shaft wire into a 30KG small roll of pin shaft wire and places it on the material rack of the pin shaft blanking machine, and pinches off the wire by 10mm with a hand vise , and then use a small assorted file...

Embodiment 3

[0145] A method for assembling a timing chain, comprising the following steps: sleeve selection, pin blanking, centerless grinding, pin selection, inner and outer plate blanking, inner plate string inspection, chain assembly, pre-drawing the lower joint, measuring Length, ring head run-in, rolling, cleaning, oiling and packaging, the assembly method of the timing chain, the specific steps are as follows:

[0146] S1: Socket sorting: Pour the socket into the string inspection box, string it into the hand fork, and then visually select it to pick out cracks, large gaps, spots, pitting, rust, hard marks, and crooked sockets Unqualified products with defects on the surface are reserved;

[0147] S2: Pin shaft blanking: the operator manually changes the 80KG large roll of pin shaft wire into a 25KG small roll of pin shaft wire and places it on the material rack of the pin shaft blanking machine, and clamps off the wire by 8mm with a hand vise , and then use a small assorted file t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com