Stepless grinding and polishing device

A stepless, grinding and polishing technology, applied in the direction of grinding/polishing equipment, grinding machines, grinding machine parts, etc., can solve the problems of dragging tool mark polishing gloss, abrasive tools affecting the surface processing quality of plates, and poor surface quality , to achieve good rough grinding and polishing effect, good polishing effect, and reduce roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

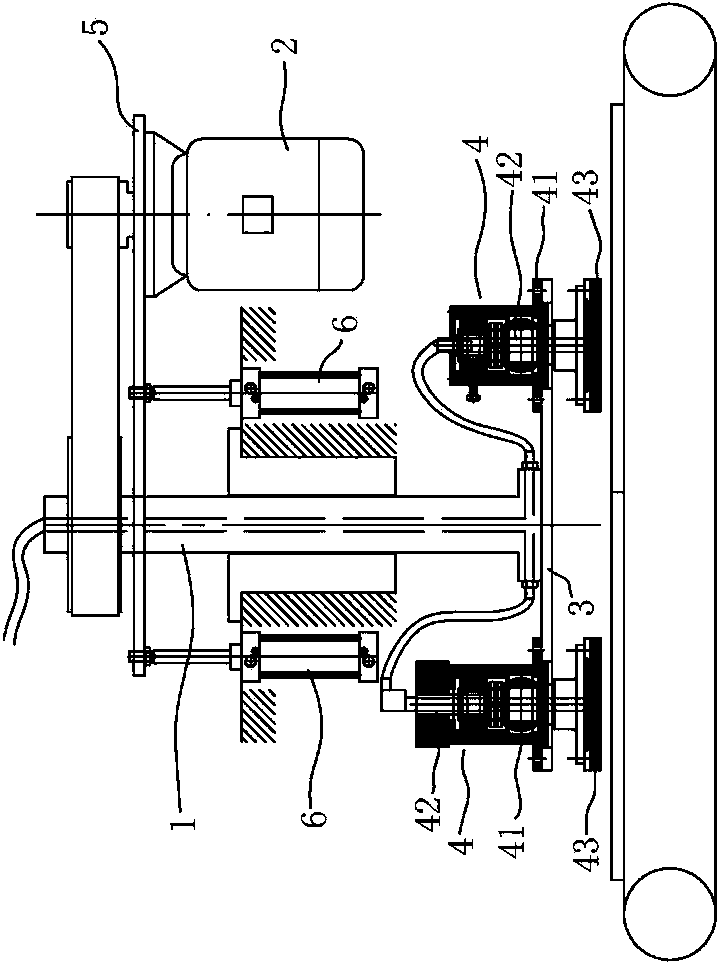

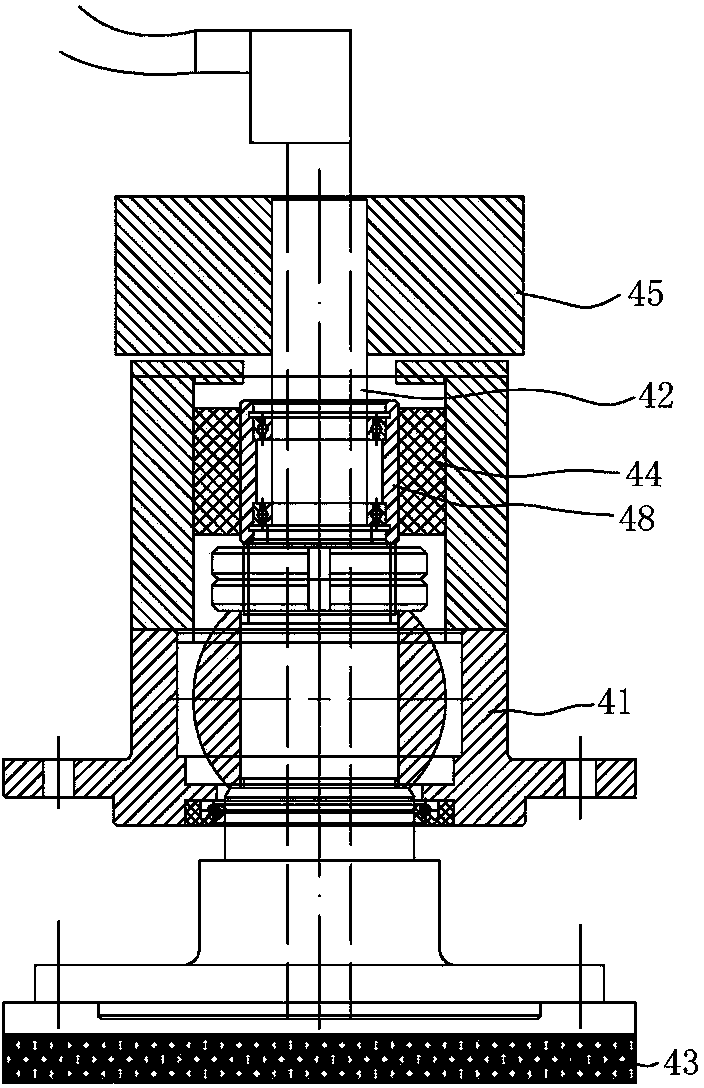

[0029] Embodiment 1, with reference to figure 1 and figure 2 , the balance device includes a balance weight 45 arranged on the upper end of the grinding wheel shaft 42 . The balance counterweight 45 can balance the centrifugal force at both ends of the joint bearing.

Embodiment 2

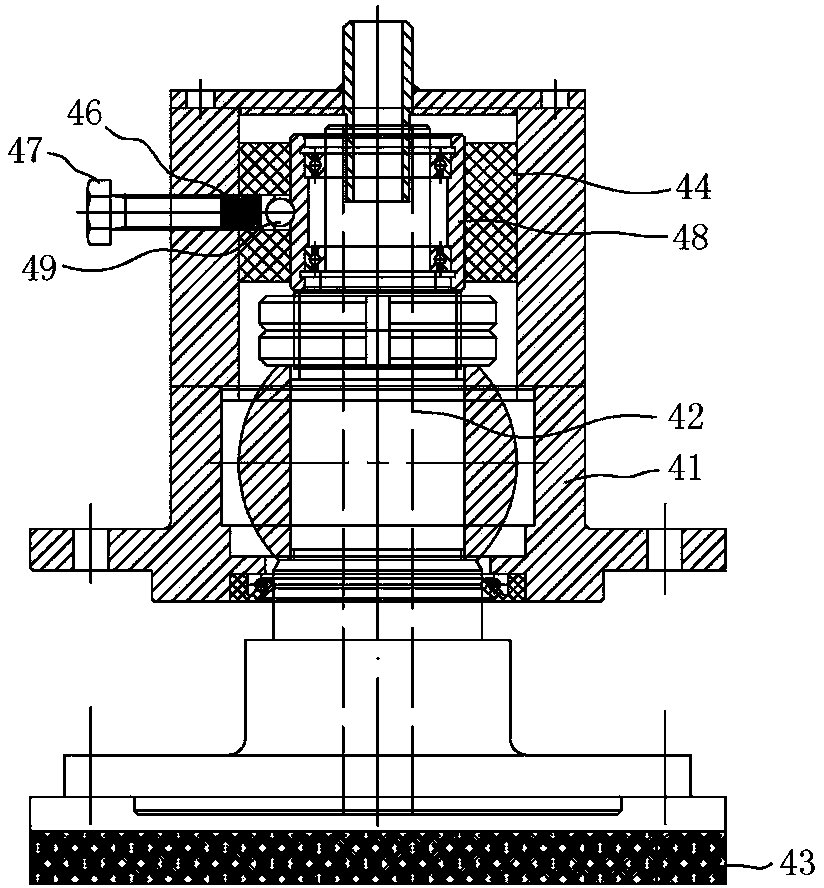

[0030] Embodiment 2, with reference to figure 1 and image 3 , the balance device includes a ball 49 that can be radially adjusted and limited, and directly or indirectly abuts against the upper section of the grinding wheel shaft 42 .

[0031]Specifically, the balance device also includes a radially arranged compression spring 46. The compression spring 46 has a fixed end and a movable end. The direction of the block toward the grinding wheel shaft 42 is a concave spherical surface, and the ball is supported by the concave spherical surface. The fixed end of the compression spring 46 is connected with the compression adjustment screw rod 47 , and the compression adjustment screw rod 47 is screwed with the radial position adjustment screw hole arranged on the grinding head fixing seat 41 . That is to say, the order of the balancing device accessories from outside to inside is: compression adjustment screw rod 47-compression spring 46-the bump with concave spherical surface-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com