Preparation method of Ti-6Al-4V alloy welding wire suitable for repair welding of titanium alloy casting

A technology of alloy welding wire and titanium alloy wire, which is applied in welding equipment, metal processing equipment, welding medium, etc., can solve the problems of welding wire production control and unsatisfactory quality level, and achieve the effect of preventing further corrosion and removing surface dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

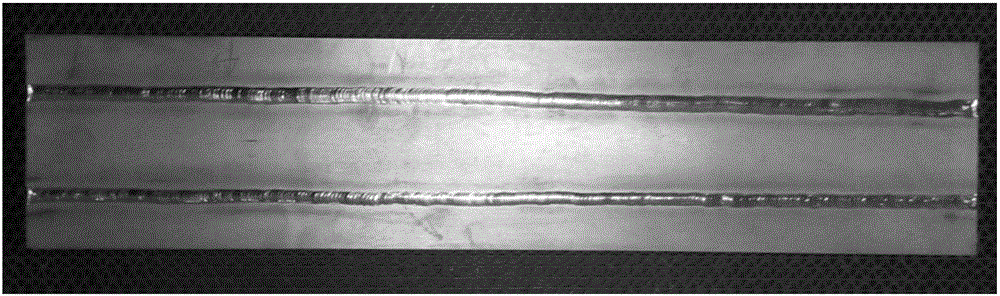

[0025] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

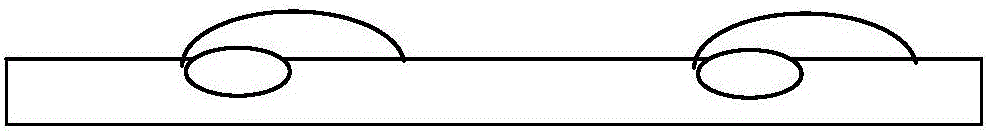

[0026] A kind of preparation technology of the Ti-6Al-4V alloy welding wire that is applicable to the repair welding of titanium alloy casting is characterized in that it is implemented according to the following steps:

[0027] (1) The composition control (weight percentage) of the Ti-6Al-4V alloy within the scope of the present invention meets GB / T 3623-2007: Al: 5.50% to 6.75%; V: 3.50% to 4.50%; O: ≤0.18% ; Fe≤0.25%; the balance is Ti and unavoidable impurity elements.

[0028] (2) The smelting process of the titanium alloy within the composition scope of the present invention is as follows: the raw material adopts first-grade sponge titanium, and sponge titanium, aluminum vanadium alloy (product parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com