Guide wheel modifier for centerless grinding machine

A centerless grinding machine and guide wheel technology, used in grinding machine parts, grinding/polishing equipment, abrasive surface adjustment devices, etc. The mobile dovetail cannot work, etc., to achieve the effect of low input processing cost, flexible height adjustment and horizontal movement, and solving the problem of frequent maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] specific implementation plan

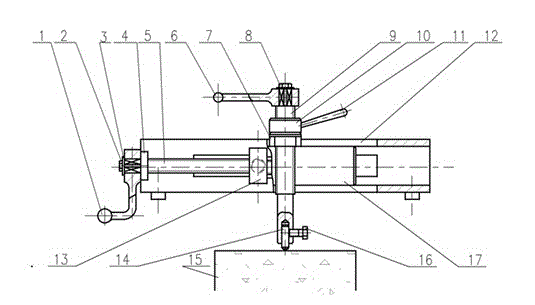

[0016] In order to further understand the centerless grinder guide wheel corrector, the accompanying drawings are described as follows.

[0017] It includes: a trimmer main body 12, a horizontal movement mechanism and an up and down movement mechanism; the horizontal movement mechanism and the up and down movement mechanism are provided on the trimmer main body 12;

[0018] Described horizontal movement mechanism comprises sliding body 17, slide block screw nut 13 and horizontal movement screw mandrel 5, and horizontal movement screw mandrel 5 top is provided with horizontal movement handle 1, and horizontal movement handle 1 is fixed by fastening bolt 2 and pad 3 and is connected with The horizontally moving screw rod 5 is connected; the horizontally moving screw rod 5 drives the slider nut 13 to move horizontally under the drive of the horizontally moving handle 5, and the slider nut 13 is fixed on the sliding body 17 by a screw rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com