Preparation method of nickel-based high-temperature alloy Inconel718 spring wire

A nickel-based superalloy and spring wire technology, applied in the field of high-temperature alloy wire preparation, can solve the problems of uneven wire structure, small pass processing rate, poor production environment, etc., and achieve excellent mechanical properties, good surface quality, The effect of less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

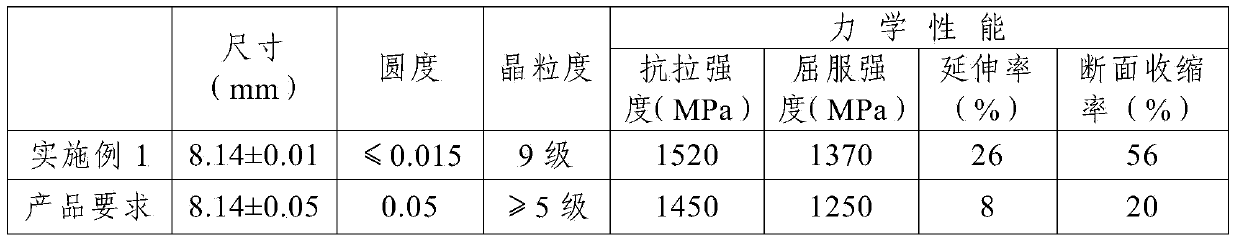

Embodiment 1

[0022] Step 1, the solid solution state nickel-based superalloy Inconel718 bar material that diameter is 14.0mm is carried out roll die drawing, obtains the wire blank that diameter is 10.5mm, and the total processing ratio of roll die drawing is 43.8%;

[0023] Step 2, placing the wire blank described in step 1 in a resistance furnace for solution heat treatment, then quenching the solution heat-treated wire blank, and then pickling the quenched wire blank treatment; the temperature of the solution heat treatment is 970 °C, and the holding time of the solution heat treatment is 60 minutes; the method of the pickling treatment is: soak the quenched silk blank in the pickling solution for 15 minutes, take out Rinse with water and dry, where the pickling solution is made of HNO 3 , HF and H 2 O is mixed according to the volume ratio of 4:2:4;

[0024] Step 3, carry out roll die drawing to the wire material blank after pickling treatment in step 2, obtain the wire material blan...

Embodiment 2

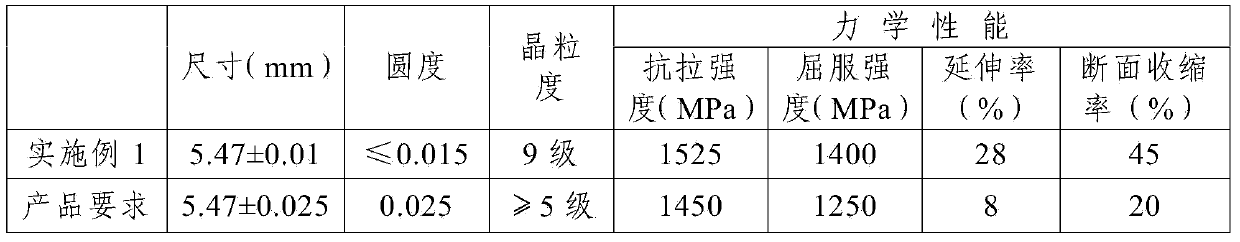

[0032] Step 1. Carrying out roll die drawing of solid solution nickel-based superalloy Inconel718 bar with a diameter of 12.0 mm to obtain a wire blank with a diameter of 8.5 mm, and the total processing rate of roll die drawing is 49.8%;

[0033] Step 2, placing the wire blank described in step 1 in a resistance furnace for solution heat treatment, then quenching the solution heat-treated wire blank, and then pickling the quenched wire blank treatment; the temperature of the solution heat treatment is 960°C, and the holding time of the solution heat treatment is 40 minutes; the method of the pickling treatment is: soak the quenched silk blank in the pickling solution for 20 minutes, take out Rinse with water and dry, where the pickling solution is made of HNO 3 , HF and H 2 O is mixed according to the volume ratio of 4:2:4;

[0034] Step 3, carrying out roll die drawing on the wire blank after pickling treatment in step 2 to obtain a wire blank with a diameter of 6.7mm, and...

Embodiment 3

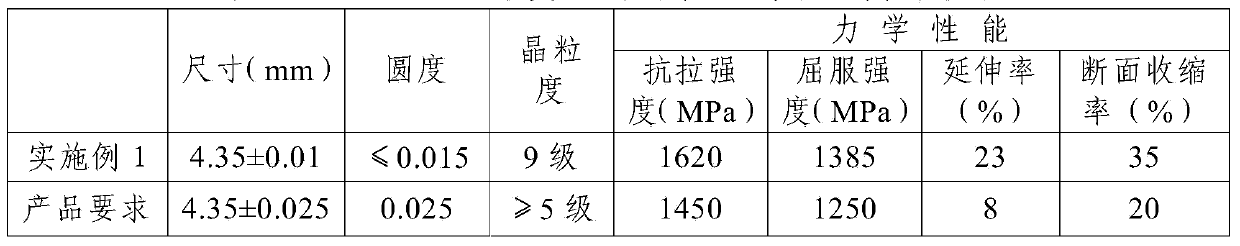

[0044] Step 1. Carrying out roll die drawing of solid solution nickel-based superalloy Inconel718 bar with a diameter of 12.0 mm to obtain a wire blank with a diameter of 9.0 mm, and the total processing rate of roll die drawing is 43.8%;

[0045] Step 2, placing the wire blank described in step 1 in a resistance furnace for solution heat treatment, then quenching the solution heat-treated wire blank, and then pickling the quenched wire blank treatment; the temperature of the solution heat treatment is 965 °C, and the holding time of the solution heat treatment is 60 minutes; the method of the pickling treatment is: soak the quenched silk blank in the pickling solution for 18 minutes, take out Rinse with water and dry, where the pickling solution is made of HNO 3 , HF and H 2 O is mixed according to the volume ratio of 4:2:4;

[0046] Step 3, carrying out roll die drawing on the wire blank after pickling treatment in step 2 to obtain a wire blank with a diameter of 7.0mm, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com