Novel centerless grinding device for pole blank

A processing device and centerless grinding technology, which is applied to machine tools designed for grinding the rotating surface of workpieces, grinding feed movement, metal processing equipment, etc., can solve the problem that the feeding mechanism is not perfect, the practicability needs to be improved, and it is unfavorable for large batches. Processing and other issues, to achieve the effects of mass production, novel and reasonable structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

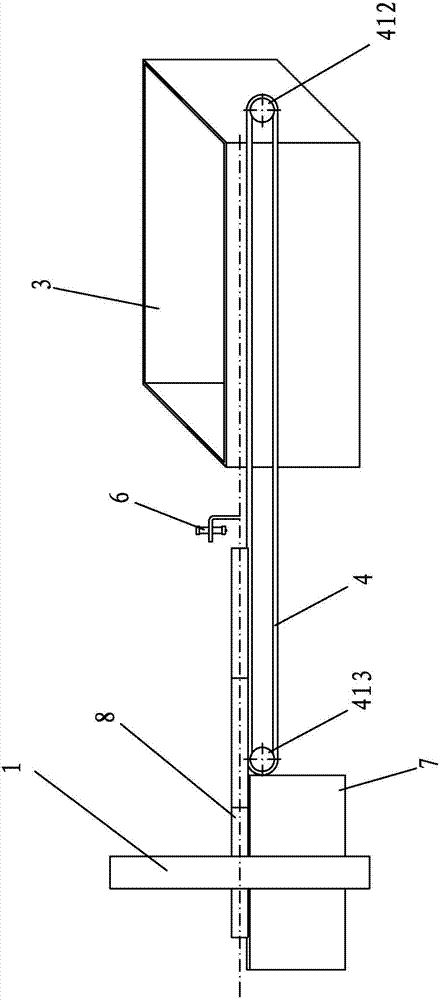

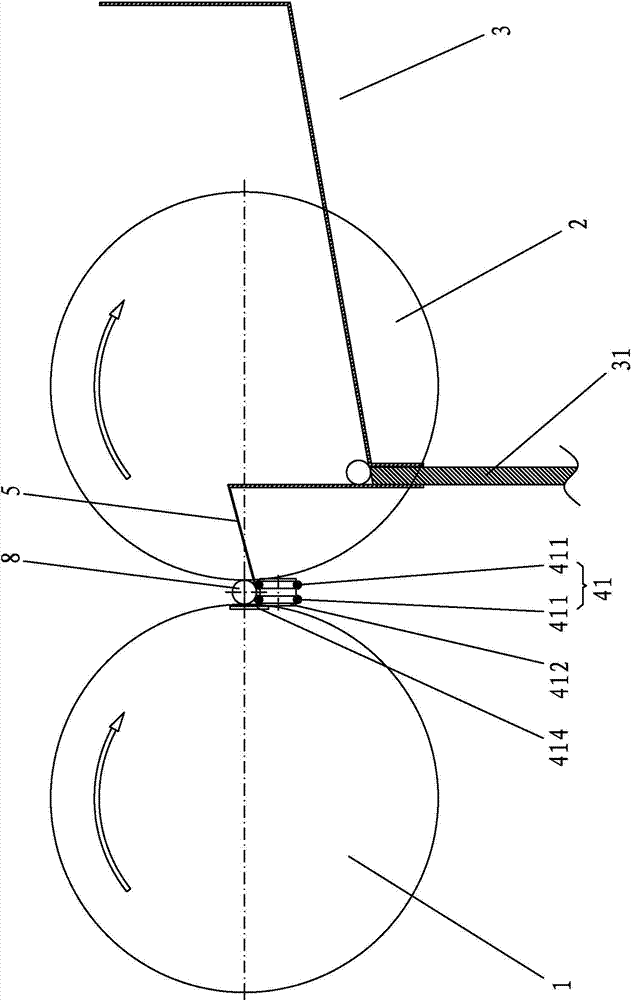

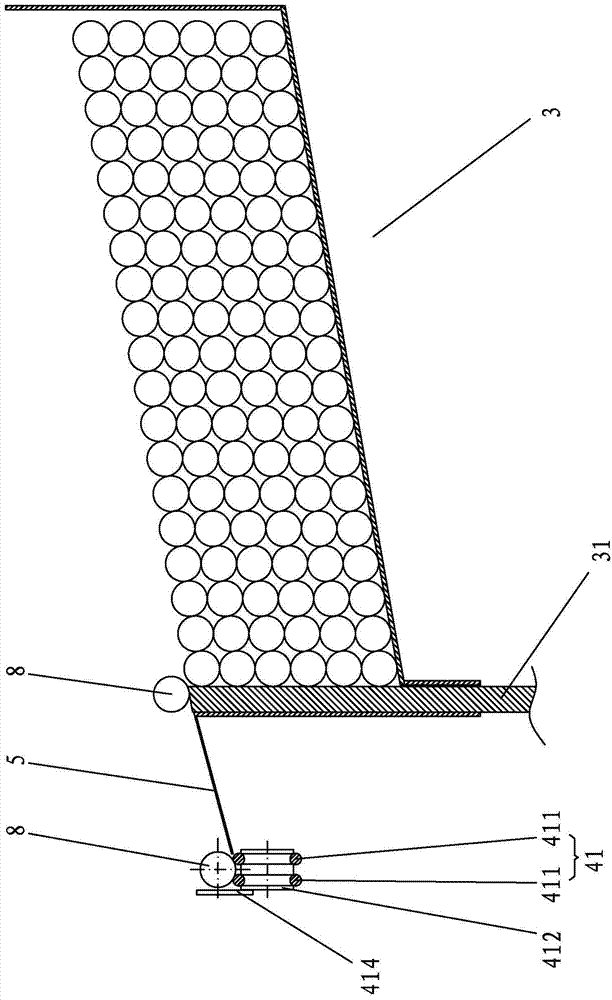

[0028] The novel centerless grinding processing device of a kind of round bar blank of the present invention, as Figure 1-4 Shown, including grinding mechanism and feeding mechanism.

[0029] The grinding mechanism includes a grinding wheel 1 and a guide wheel 2 that rotate in the same direction. The grinding wheel 1 and the guide wheel 2 are close to tangent, but there is a space for the round bar blank 8 between them. The rotation speed of the grinding wheel 1 is greater than that of the guide wheel 2. The rotational speed is used to realize the grinding of the round bar blank 8 by the grinding wheel 1 by using this speed difference;

[0030] The feeding mechanism includes a material storage box 3 for containing the round bar blank 8, and a delivery device 4 for transporting the round bar blank 8 to the grinding wheel 1 and the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com