Mirror face stainless steel bearing and process thereof

A technology of mirror surface stainless steel and processing technology, which is applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of poor corrosion resistance, loss of bearing function, environmental pollution, etc., to improve surface finish, increase strength, enhance the aesthetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

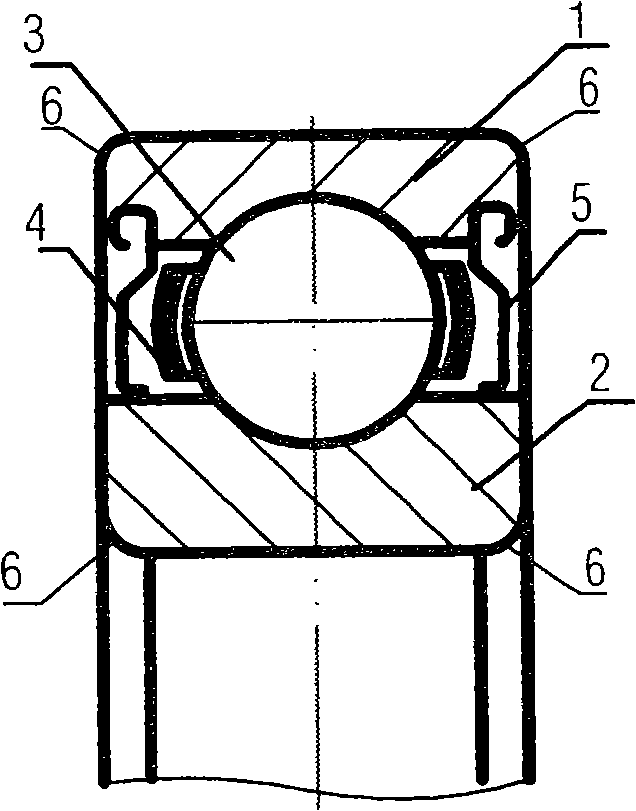

[0051] 6201ZZ mirror surface stainless steel bearing and processing technology (dimensions 12×32×10)

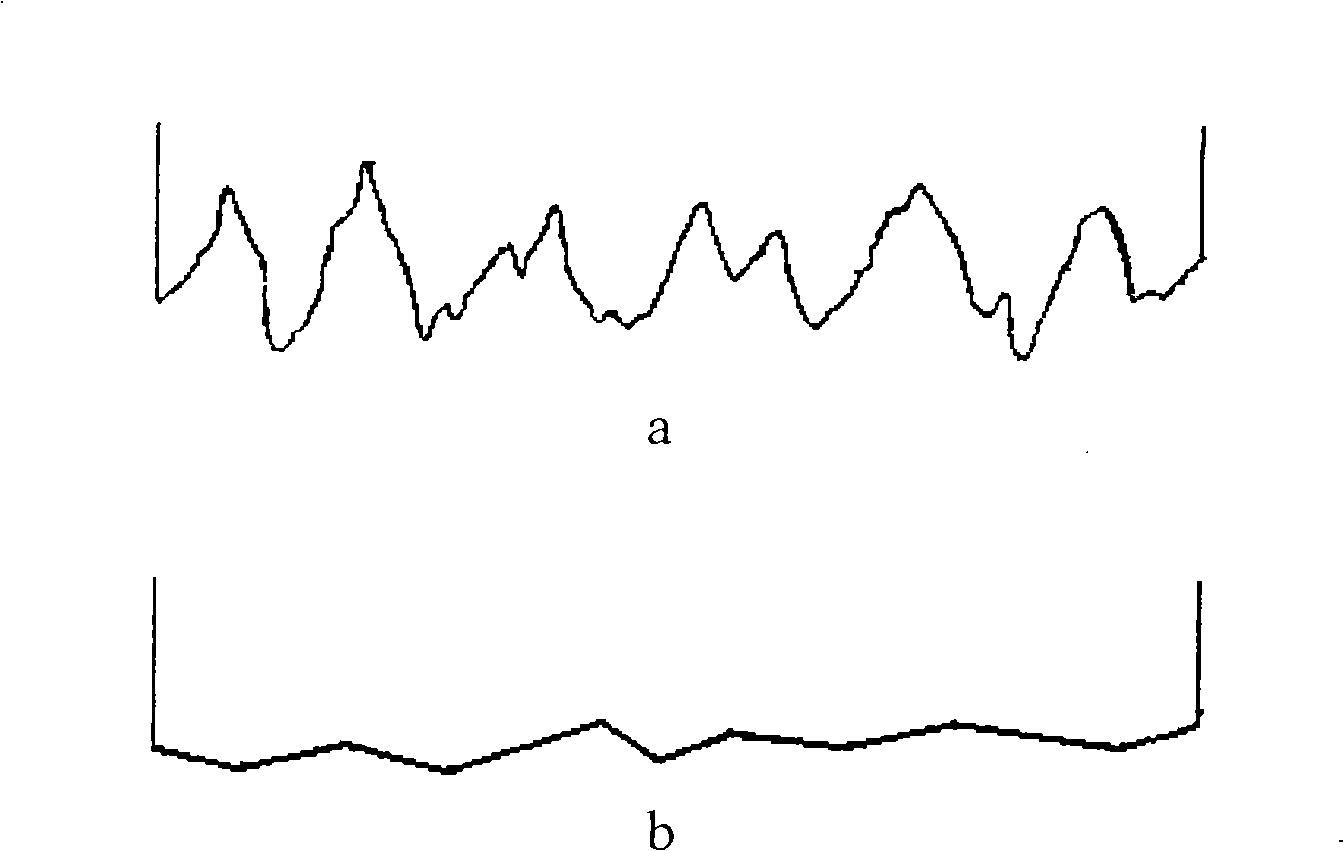

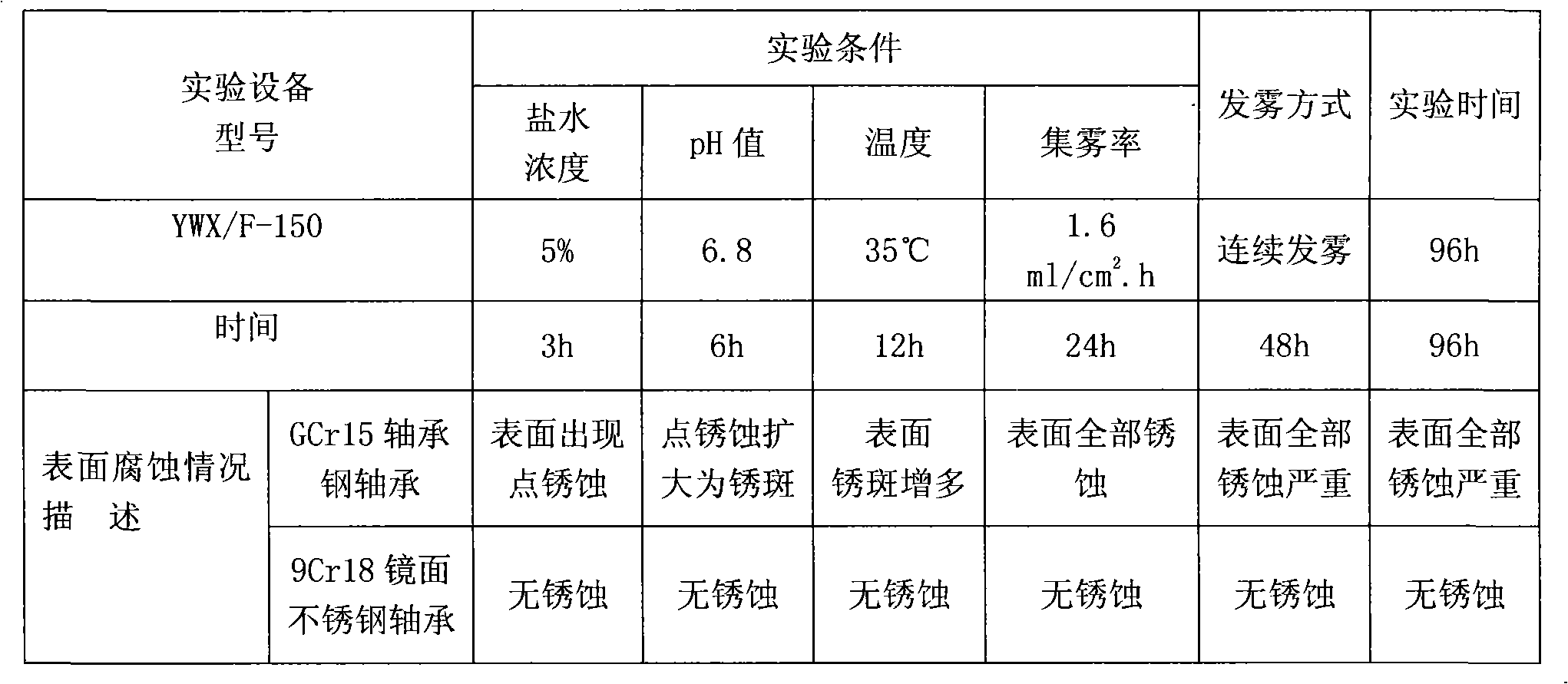

[0052] The 9Cr18 stainless steel bar is turned into a ring shape according to the feeding process regulations. After soft grinding, surface grinding and cylindrical grinding, it enters the turning process, and the acute angle is removed, the tooth socket is turned, the inner and outer ring grooves are turned, and it enters the heat treatment. 6201ZZ is a small deep groove ball bearing. The walls of the two rings are not very thick, and the temperature is not easy to be too high during heat treatment. The processing technology is: first, the inner and outer rings of the bearing are preheated to 850-860 ° C, kept for 12 hours and then heated to Heat at 1090-1100°C for 7 hours, cool the oil to 40°C and put it into the freezer for cryogenic treatment to -75°C for 1 hour, then heat it in a splash furnace to 150-160°C for 3 hours, then perform sandblasting , under the action of hig...

Embodiment 2

[0055] 6306ZZ mirror surface stainless steel bearing and processing technology (dimensions 30×72×19)

[0056] The 9Cr18 stainless steel bar is turned into a ring shape according to the feeding process regulations. After soft grinding, surface grinding and cylindrical grinding, it enters the turning process for submitting to the turning process, and the acute angle is removed, the tooth socket is turned, the inner and outer ring grooves are turned, and it enters the heat treatment. 6306ZZ is a medium-sized deep groove ball bearing, the wall of the two rings is thicker, the temperature can be higher during heat treatment, and the holding time can be longer. The processing technology is: first preheat the inner and outer rings of the bearing to 850-860°C, keep it warm for 16 hours, then heat it to 1090-1100°C and keep it warm for 10 hours, then cool the oil to 40°C and put it into the refrigeration equipment for cryogenic treatment to -80°C The holding time is 1.5 hours, and then...

Embodiment 3

[0058] 61905ZZ mirror stainless steel bearing and processing technology (dimensions 25×42×9)

[0059] The 9Cr18 stainless steel bar is turned into a ring shape according to the feeding process regulations. After soft grinding, surface grinding and cylindrical grinding, it enters the turning process for submitting to the turning process, and the acute angle is removed, the tooth socket is turned, the inner and outer ring grooves are turned, and it enters the heat treatment. 61905ZZ is a light series deep groove ball bearing. The wall of the two rings is very thin, which is prone to heat treatment deformation. During the heat treatment process, the temperature should be as low as possible under the premise of ensuring the quality of the heat treatment, and the holding time should be shorter. The processing technology is: first preheat the inner and outer rings of the bearing to 850-860°C, keep it warm for 10 hours, then heat it to 1090-1100°C and keep it warm for 6 hours, then co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com