Sow feed mixing method and mixing equipment

A technology for mixing equipment and sow feed, which is applied in the direction of feed, mixers with rotating containers, mixers, etc., can solve problems such as lack of reach, uneven mixing, and decreased lactation, and achieve a simple structure and ingenious design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

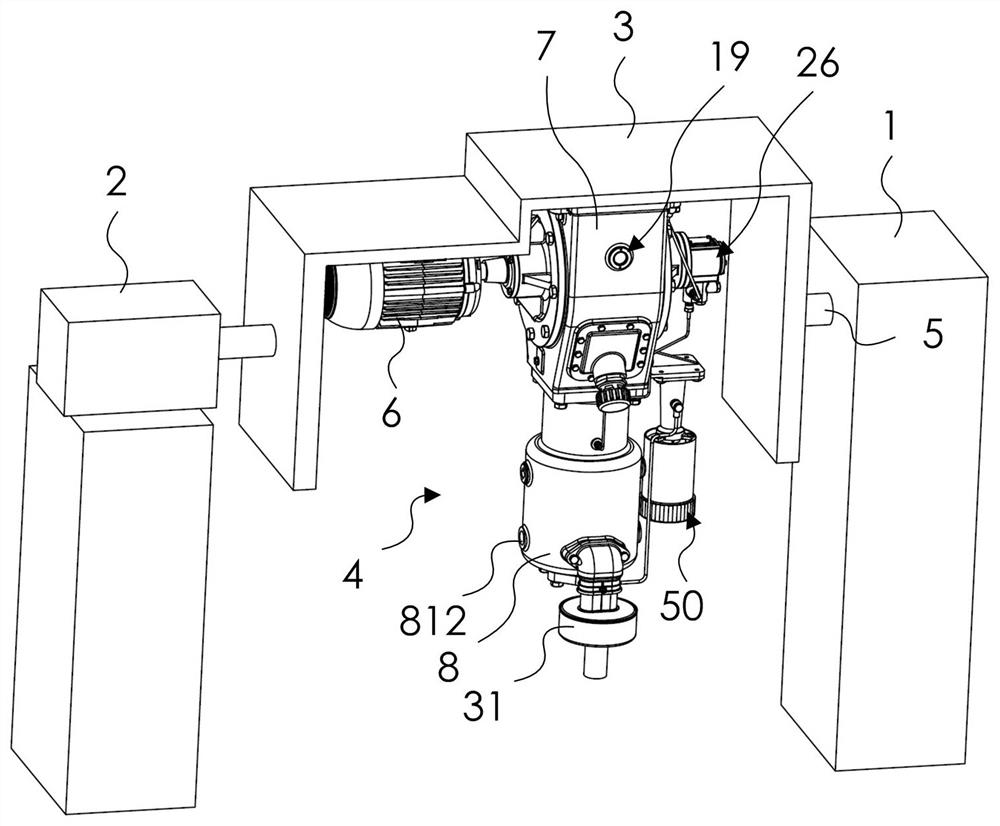

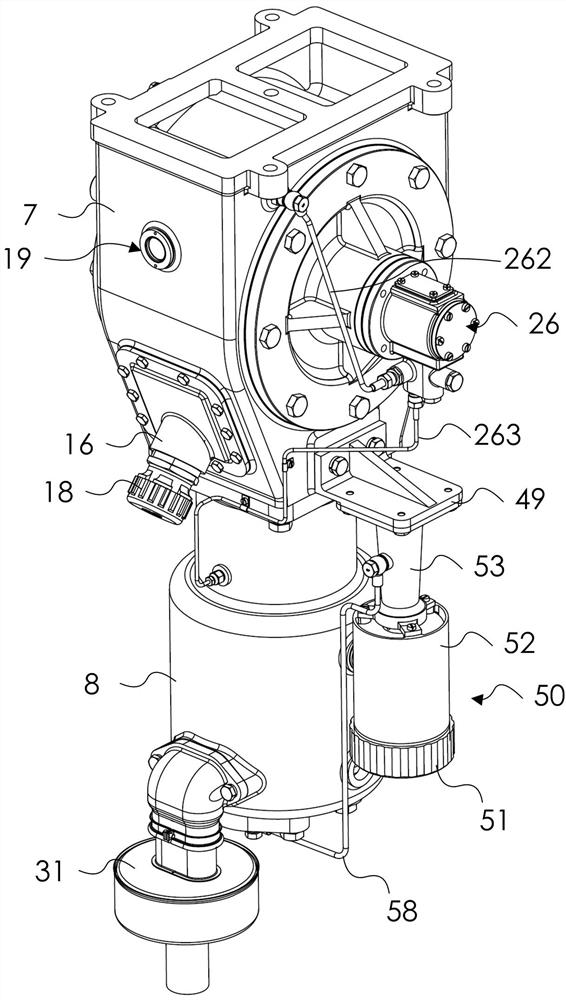

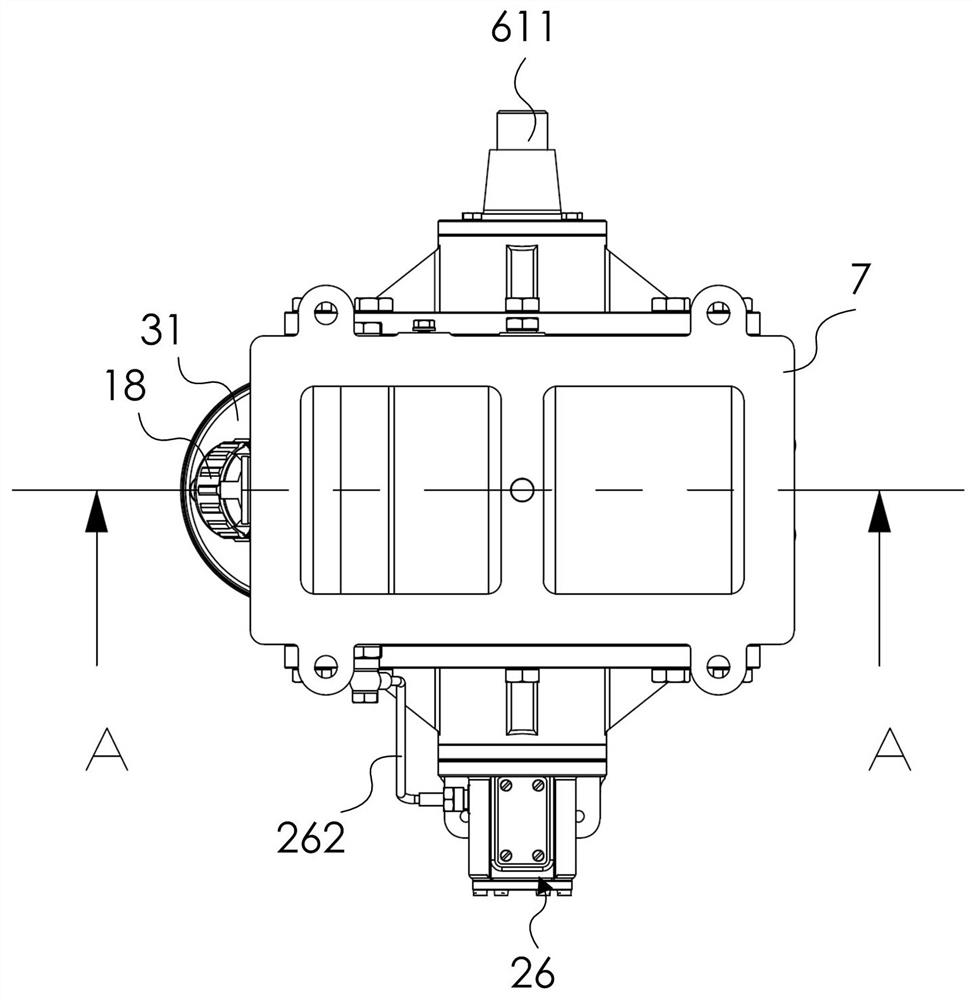

[0046] Such as Figures 1 to 13 As shown, the mixing equipment of this sow feed of the present invention adopts a variety of feeding methods and different time periods of feeding to process sow feed, through the first mixing chamber 7 and the second mixing chamber 7 in the mixing assembly 4 Room 8 mixes feed for pregnant sows and feed for lactating sows. The feed for pregnant sows and feed for lactating sows refers to the invention patent CN103461742B, which is named feed for pregnant sows and feed for lactating sows mentioned in feed for sows and its breeding mode. When mixing, first grind the raw materials in the feed for pregnant sows and the feed for lactating sows into powder, then inject the additive liquid according to the proportion and then add it to the mixing assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com