Stirring device and stirring method

The technology of a stirring device and a stirring tank is applied to mixers with rotating stirring devices, chemical instruments and methods, and mixer accessories, etc., which can solve the problems of high safety risks of electrical equipment, increased industrial energy consumption, and high use costs, and achieve Eliminate safety risks of electrical equipment, reduce energy consumption and noise pollution, and have simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order for those skilled in the art to better understand the technical solutions of the present disclosure, the present disclosure will be further described in detail below with reference to the accompanying drawings and specific embodiments.

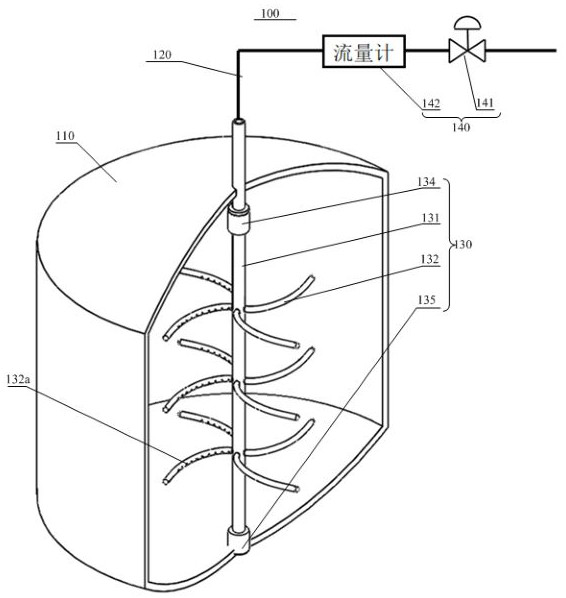

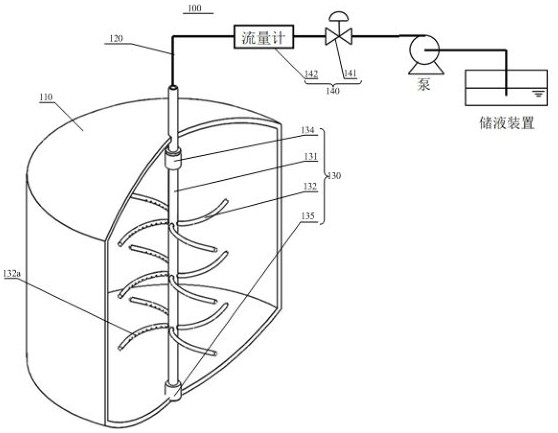

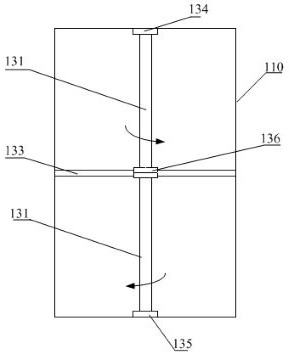

[0028] like figure 1 As shown, the embodiment of the present disclosure relates to a stirring device 100 , and the stirring device 100 includes a stirring tank 110 , a liquid inlet pipeline 120 , and a stirring assembly 130 rotatably disposed in the stirring tank 110 . The stirring assembly 130 is provided with a fluid injection channel, and the fluid injection channel communicates with the liquid inlet pipeline 120 and the stirring tank 110 respectively, so as to form a jet in the stirring tank 110, and the jet can push The stirring assembly 130 is rotated to stir the fluid in the stirring tank 110 .

[0029] Specifically, as figure 1 and figure 2 As shown, in practical application, the fluid of the liquid storage device i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com