Powder-liquid mixing machine

A mixer, powder-liquid technology, applied in the directions of mixer, mixing method, dissolution, etc., can solve the problems of difficulty in uniform mixing of powder and liquid, high viscosity, and low component content, to overcome the contradiction of clogging and dispersibility, overcome Effects of technical difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

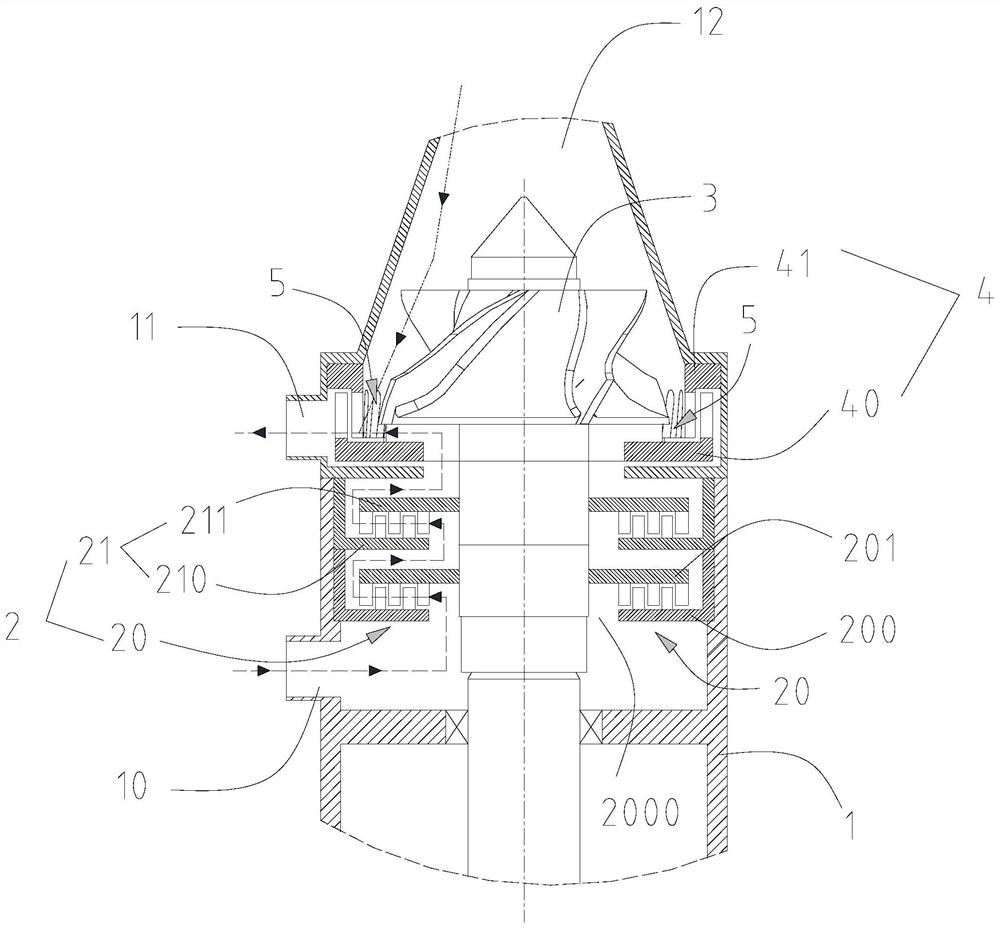

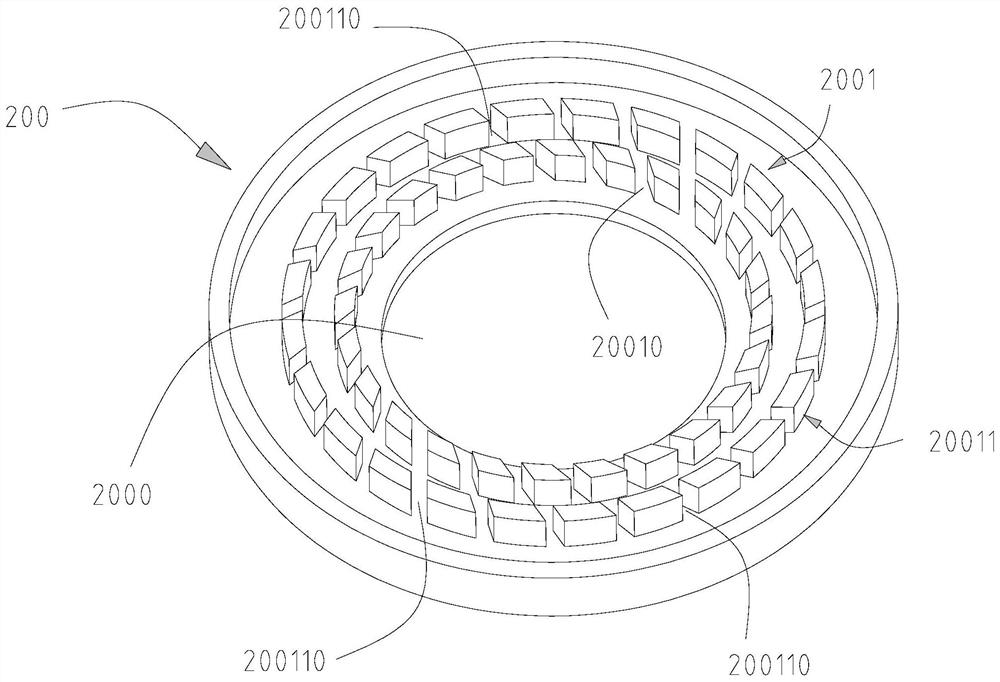

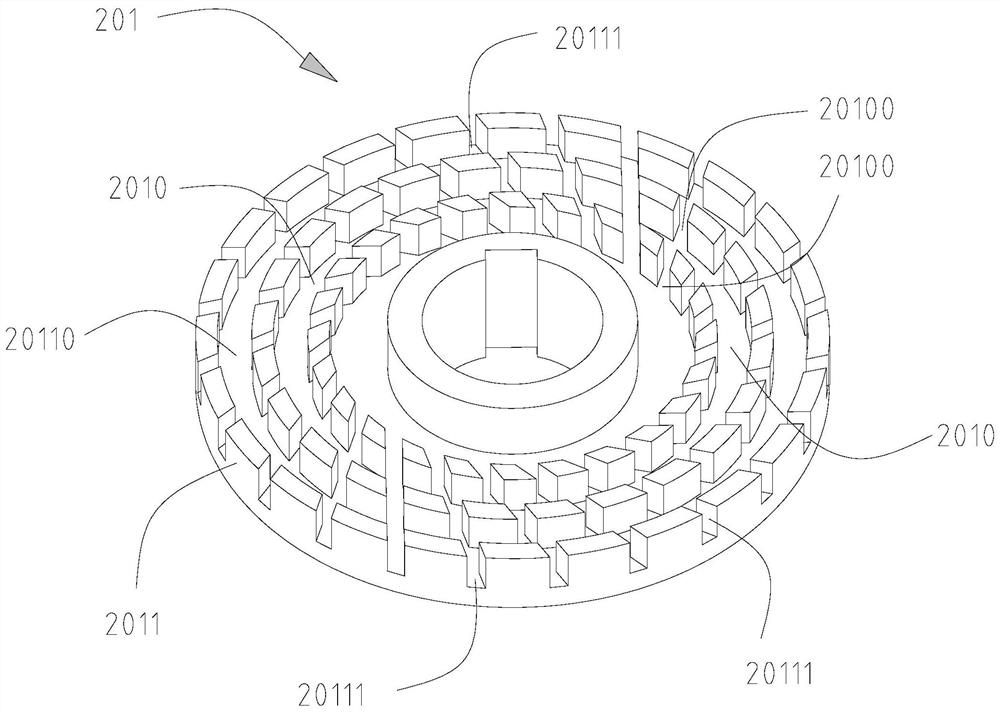

[0038] See Figure 1-9, the present invention shows a powder-liquid mixer, including a main housing 1 , a liquid dispersion device 2 , a powder conveying device 3 and a mixing device 4 . Among them, a liquid dispersion area and a powder-liquid mixing area are formed in the main housing 1, and the main housing 1 is provided with a liquid inlet, a powder feed port 12 and a mixing discharge port 11, and the liquid to be mixed enters through the liquid inlet. The liquid dispersing area is dispersed through the liquid dispersing device 2 installed in the liquid dispersing area, and the dispersed liquid to be mixed enters the powder-liquid mixing area under the action of the liquid dispersing device 2; the powder to be mixed is fed from the powder Port 12 enters the main housing 1, and the powder to be mixed entering the main housing 1 is transported into the powder-liquid mixing area through the powder delivery device 3; The powder to be mixed in the powder-liquid mixing zone is m...

Embodiment 2

[0058] Such as Figure 9 As shown, embodiment 2 also includes a circulating liquid tank 6 on the basis of embodiment 1, the mixing outlet 11 communicates with the inlet of the circulating liquid tank 6, the outlet of the circulating liquid tank 6 is connected to the liquid feed port 10, and the circulating liquid tank A liquid flow pump 7 is set between the outlet of 6 and the liquid feed port 10, and the slurry in the circulating liquid tank 6 is input into the liquid dispersion area through the liquid flow pump 7, and after being dispersed by the liquid dispersion device 2, it enters the powder mixing area and After the powders to be mixed are mixed, they enter into the circulating liquid tank 6 from the mixing discharge port 11, and thus circulate. That is to say, embodiment 2 can realize multiple circulation dispersion mixing of the slurry, so that the dispersion mixing effect is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com