Enzymatic microbial strain liquid fermentation system

A microbial strain, liquid fermentation technology, applied in enzymology/microbiology device, bioreactor/fermenter combination, bioreactor/fermenter for specific purposes, etc. Mixing and dissolving with strain liquid to achieve the effect of improving quality, avoiding precipitation, and accelerating mixing and dissolving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

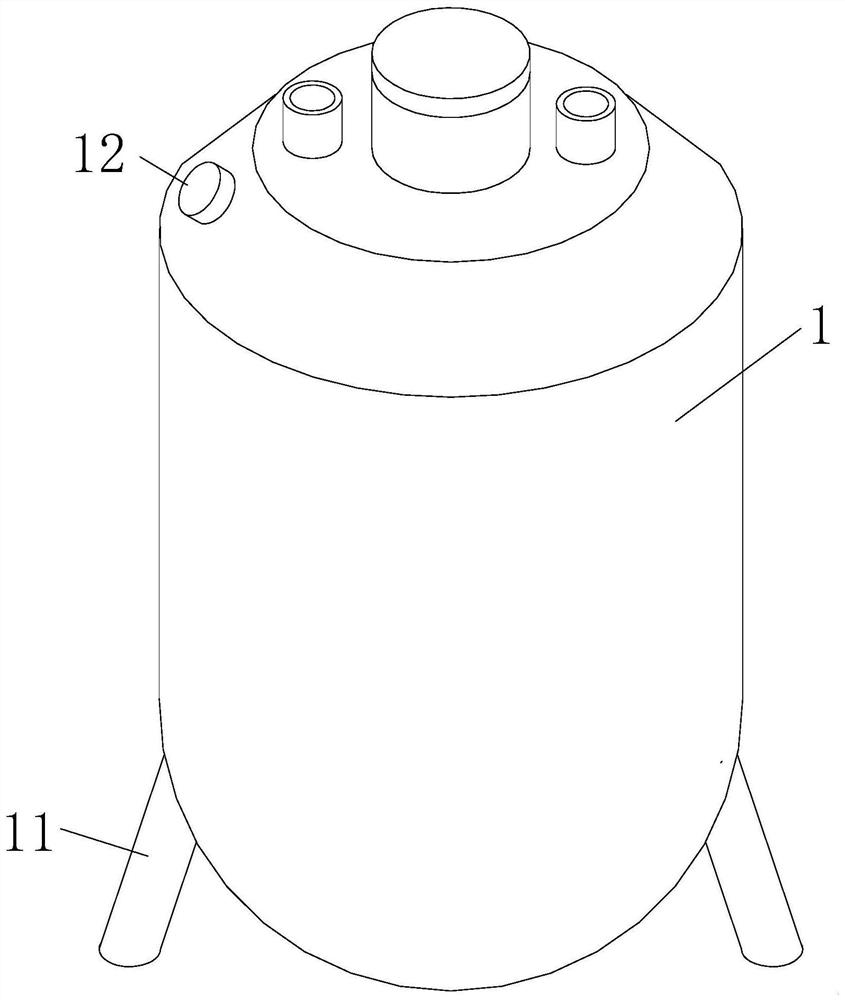

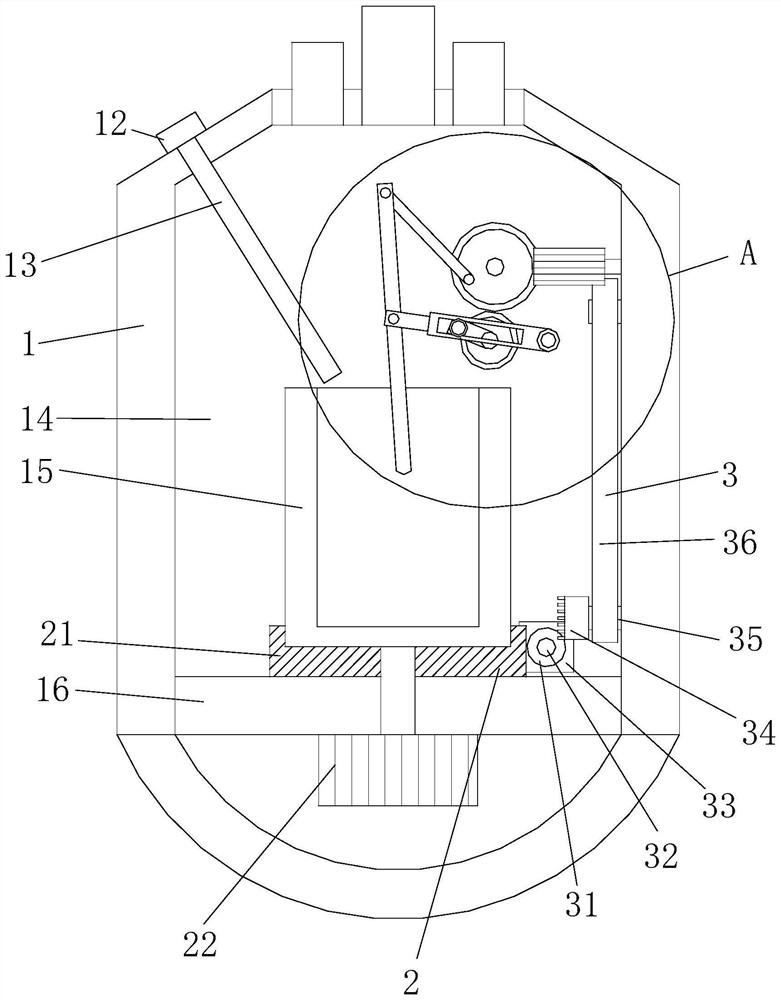

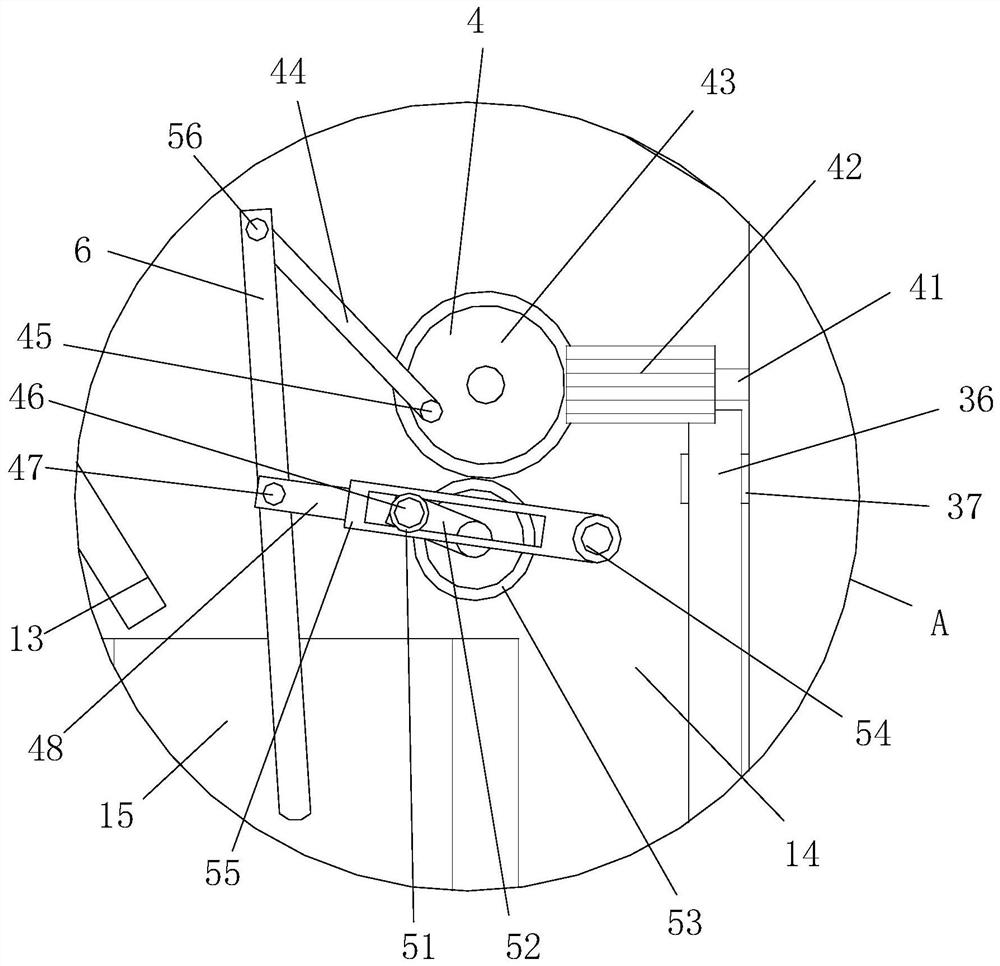

[0037] see Figure 1-3 , the present invention provides a technical solution: a liquid fermentation system for enzymatic microbial strains, comprising a tank body 1 and a fermenter barrel 15, the lower surface of the tank body 1 is fixedly connected with three bottom columns 11, and the inside of the tank body 1 is provided with Inner chamber 14, fermenter barrel 15 is arranged in the inside of inner chamber 14, and the inside of inner chamber 14 is provided with feed pipe 13, and the upper end of feed pipe 13 is fixed to pass through the inner wall of inner chamber 14 and extends out of the outside of tank body 1, enters The inside of the feeding pipe 13 is set to be hollow, and the feeding pipe 13 is arranged in an inclined shape. The feeding pipe 13 is located above the fermenter 15. The upper end of the feeding pipe 13 is movably engaged with a plug cover 12, and the inner wall of the inner chamber 14 A partition 16 is fixedly connected, and a horizontal rotation mechanism...

Embodiment 2

[0044] On the basis of embodiment one, refer to Figure 4 , the lower surface of the stirring wing 6 is fixedly connected with a liquid analysis ring 7, the liquid analysis ring 7 includes a ring body 71, the ring body 71 is arranged in a ring shape, and the inside of the ring body 71 is fixedly connected with two circular shafts 74, two The circular shafts 74 are respectively arranged on the upper and lower sides of the ring body 71, and the outside of each circular shaft 74 is fixedly sleeved with a slant plate 72, and the slant plate 72 is arranged in an inclined shape inside the ring body 71. The upper surface of 72 is evenly divided and fixedly connected with several bumps 73, and the bumps 73 are arranged in a hemispherical shape.

[0045] When in use, by arranging the agitating wing 6 to cooperate with the liquid analysis ring 7, when the agitating wing 6 is performing longitudinal agitation inside the fermenter 15, the agitating wing 6 drives the ring body 71 to perfor...

Embodiment 3

[0047] On the basis of embodiment one, refer to Figure 5 , the lower surface of the stirring wing 6 is fixedly connected with an increasing plate 8, the increasing plate 8 includes a trapezoidal plate 81, the trapezoidal plate 81 is set to an isosceles trapezoidal shape, the lower surface of the trapezoidal plate 81 is provided with a lower notch 83, and the lower notch 83 The inner wall is fixedly connected with several net posts 82, and the net posts 82 are arranged in a net shape.

[0048] When in use, by arranging the agitating wing 6 to cooperate with the increasing plate 8, when the agitating wing 6 moves in the fermenter 15, the agitating wing 6 drives the trapezoidal plate 81 and the mesh column 82 to move synchronously to the strain liquid in the fermenter 15 At the same time, the contact area between the stirring wing 6 and the strain liquid in the fermenter 15 can be increased by means of the net column 82 and the trapezoidal plate 81. At the same time, the trapezo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com