Square cone mixing machine

A mixer and right bracket technology, applied in mixers, mixing methods, mixers with rotating containers, etc., can solve problems such as poor uniformity, dust leakage, material crushing, etc., and achieve good mixing effect and no dust Leakage, easy cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

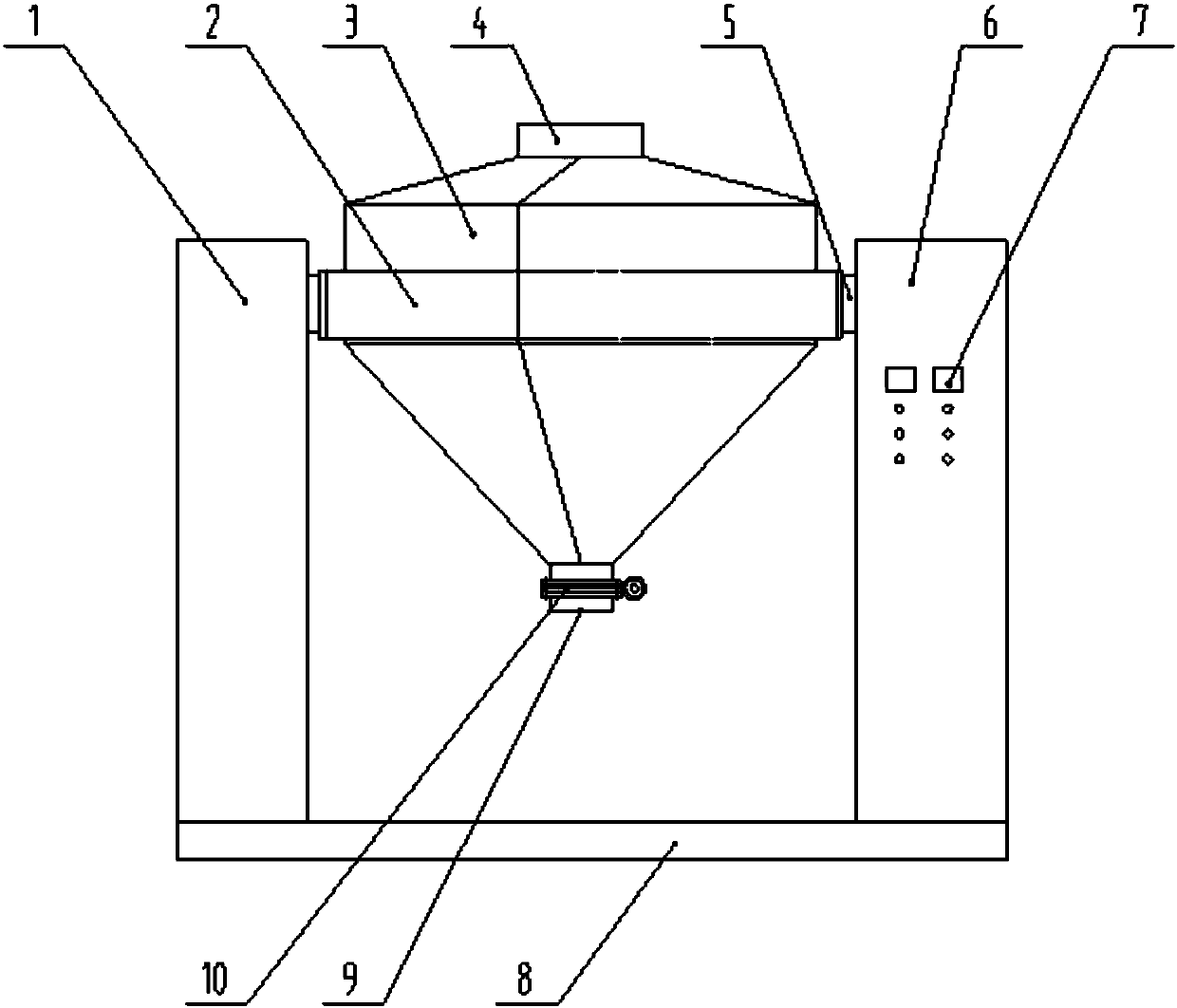

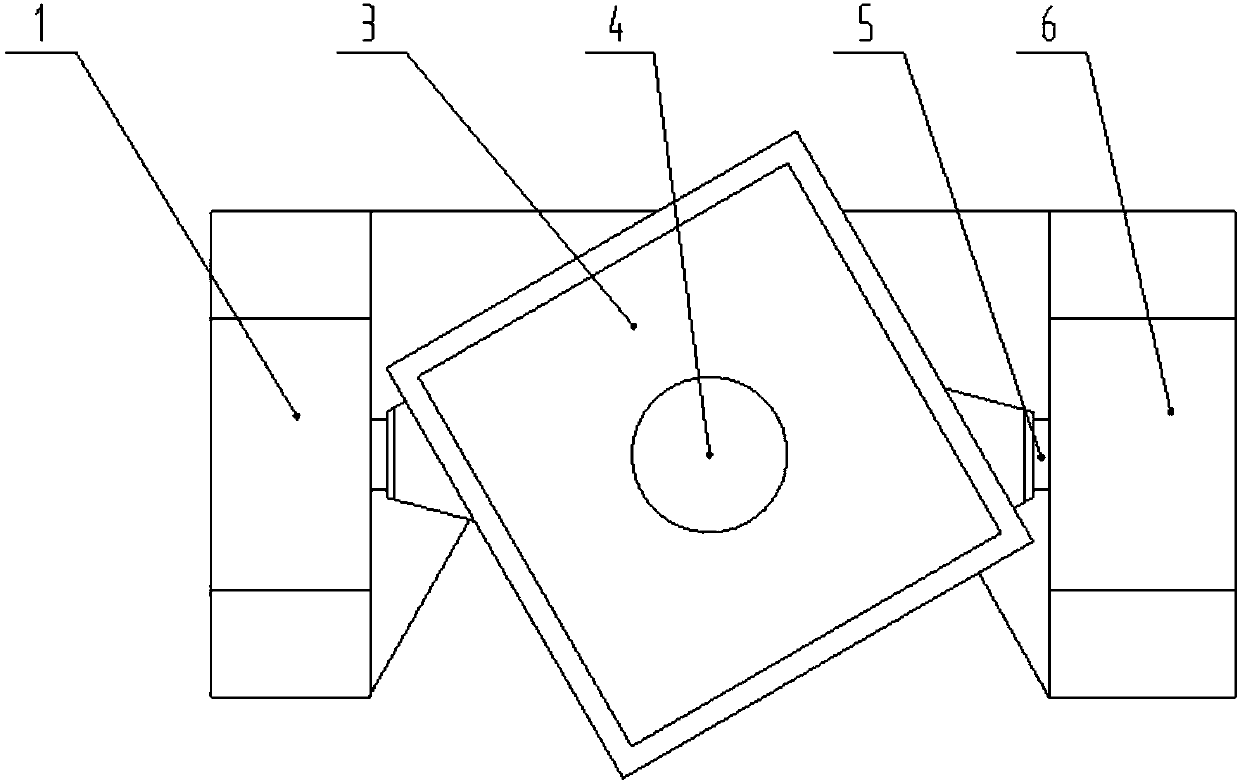

[0015] This embodiment provides a square cone mixer with a structure such as figure 1 , figure 2 As shown, it includes: a left bracket 1, a right bracket 6, a barrel 3 and a frame 2, the left bracket 1 is installed on one end of the base 8, the right bracket 6 is installed on the other end of the base 8, and a rotating shaft is installed at both ends of the frame 2 5. The frame 2 is connected with the left bracket 1 and the right bracket 6 through the bearings of the rotating shaft 5. The material cylinder 3 is fixed in the frame 2. The material cylinder 3 is a cone with the tip facing downward and protruding above. The upper end of the material cylinder 3 is provided with an inlet. Material port 4, the lower end of barrel 3 is provided with discharge port 9, motor and speed reducer are installed inside right support 6, the shaft of speed reducer and the rotating shaft 5 on the frame 2 are connected by belt.

[0016] Adopt single-cone rotary stacking material ratio, cross di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com