Preparation method of transparent ceramic for nuclear reactor observation window

A technology for observation windows and transparent ceramics, which is applied in the preparation of transparent ceramics for nuclear reactor observation windows and Y2O3 transparent ceramics. It can solve the problems of high ceramic density and cannot meet the special needs of nuclear reactor observation window materials, and achieve high ceramic density. , short preparation cycle, uniform powder size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: a kind of Y 2 o 3 The preparation method of transparent ceramics, the steps are as follows:

[0049] (1) Weigh 47.88g of yttrium nitrate hexahydrate and 19.12g of yttrium acetate tetrahydrate in a molar ratio of 1:0.45, mix them, add 250g of deionized water, stir at 70°C until a clear precursor solution is formed, and then continue stirring 1 hour to ensure that the components in the solution are uniform;

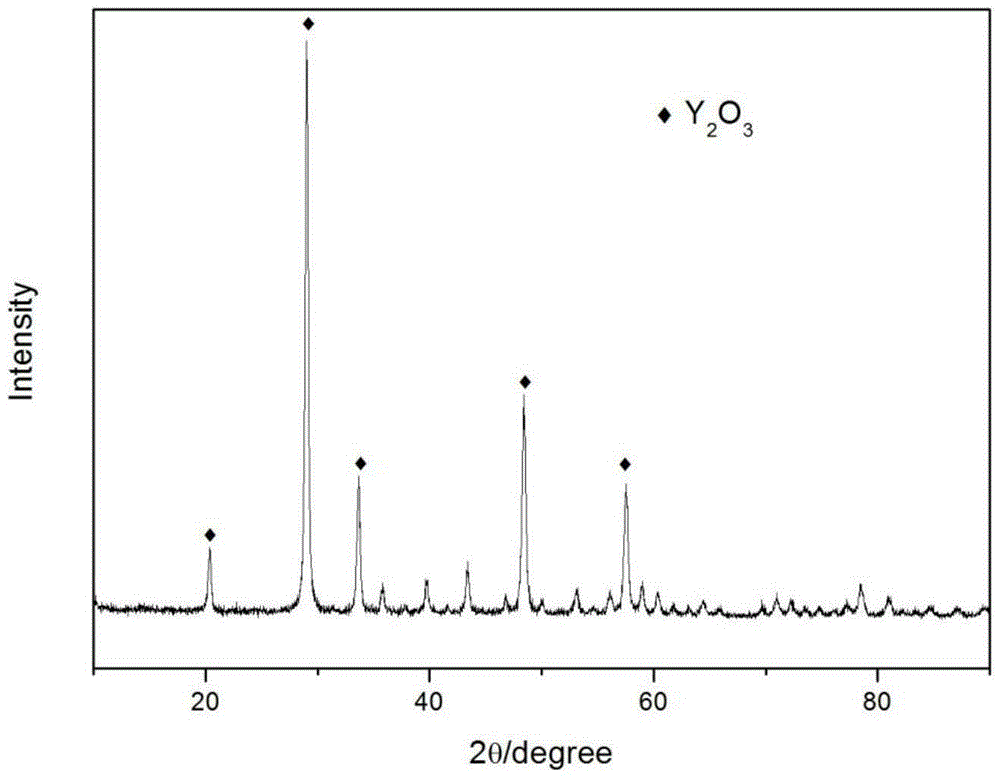

[0050] Weigh 30 g of the obtained clarified precursor solution and put it in a corundum crucible, place it in a microwave oven with a frequency of 2.45 GHz, heat it for 15 min at a power of 300 W, and undergo rapid boiling, evaporation and self-propagating combustion of the solution to obtain the average particle size 17.2nm Y 2 o 3 Powder;

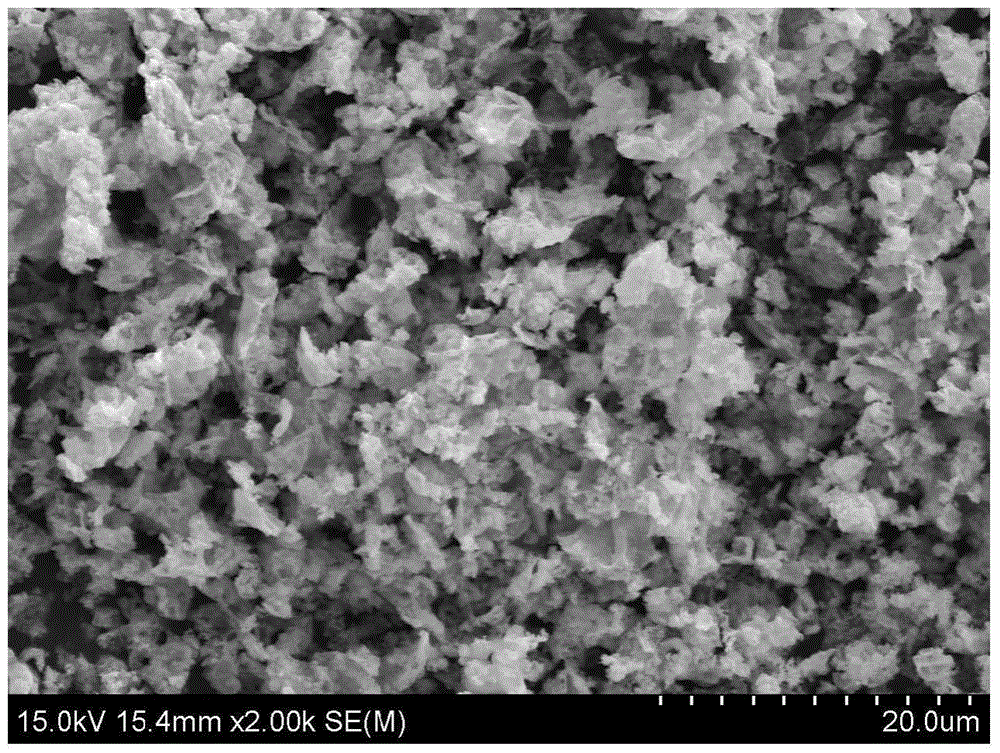

[0051] (2) Weigh 10 g of nano powder body obtained in step (1), ZrO 2 Put 200g of balls and 45g of absolute ethanol in a ball mill jar, place the ball mill jar in a planetary ball mill, and mill at a speed of...

Embodiment 2

[0056] Embodiment 2: a kind of preparation Y 2 o 3 The method of transparent ceramics, the steps are as follows:

[0057] (1) Weigh 47.88g of yttrium nitrate hexahydrate and 21.13g of yttrium acetate tetrahydrate in a molar ratio of 1:0.5, mix them, add 200g of deionized water, and stir at 50°C until a clear precursor solution is formed, then continue stirring 2 hours to ensure that the components in the solution are uniform;

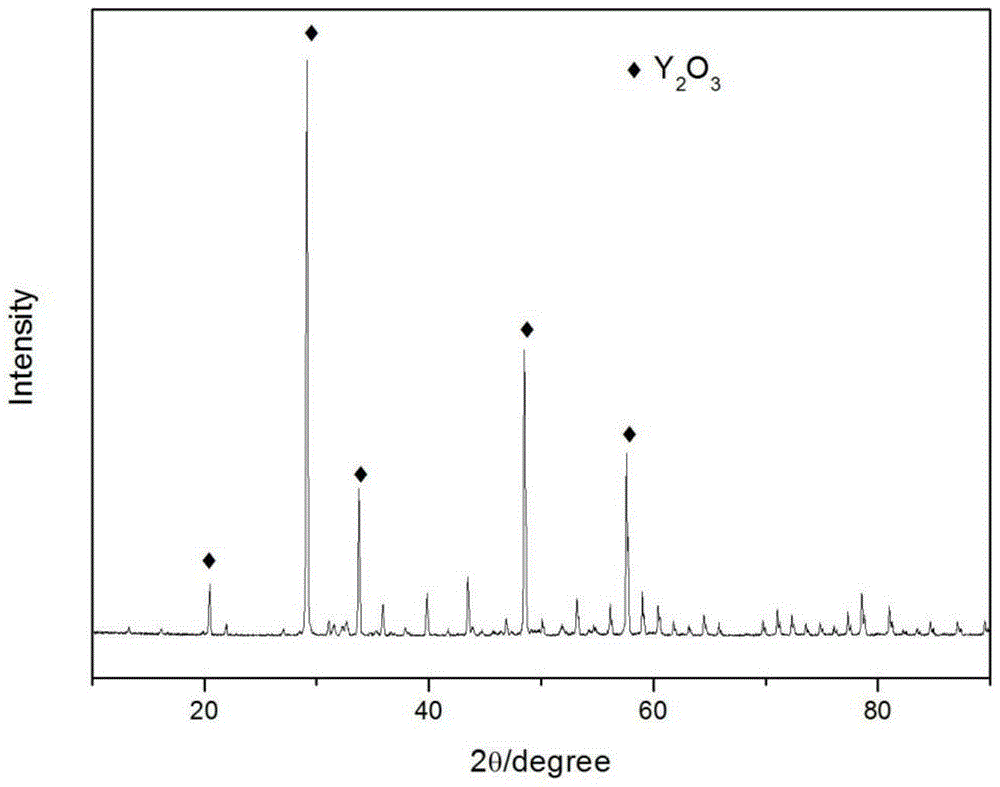

[0058] Weigh 20 g of the obtained clarified precursor solution and put it in a corundum crucible, place it in a microwave oven with a frequency of 2.45 GHz, heat it for 10 min at a power of 400 W, and undergo rapid boiling, evaporation and self-propagating combustion of the solution to obtain the average particle size 20nm Y 2 o 3 Powder;

[0059] (2) Weigh the Y obtained in step (1) 2 o 3 Powder 10g, ZrO 2 Put 160g of balls and 40g of anhydrous ethanol in a ball mill jar, put the ball mill jar in a planetary ball mill, and mill at a speed of 20...

Embodiment 3

[0061] Embodiment 3: a kind of preparation Y 2 o 3 The method of transparent ceramics, the steps are as follows:

[0062] (1) Weigh 47.88g of yttrium nitrate hexahydrate and 23.25g of yttrium acetate tetrahydrate in a molar ratio of 1:0.55, mix them, add 230g of deionized water, stir at 50°C until a clear precursor solution is formed, and then continue stirring 1.5 hours to ensure that the components in the solution are uniform;

[0063] 25g of the obtained clarified precursor solution was weighed and packed in a corundum crucible, placed in a microwave oven with a frequency of 2.45GHz, heated for 15min at a power of 4500W, and rapidly boiled, evaporated, and self-propagating combustion of the solution to obtain Y 2 o 3 Nano powder;

[0064] (2) Weigh the Y obtained in step (1) 2 o 3 Nano powder 10g, ZrO 2 Put 220g of balls and 50g of absolute ethanol in a ball mill jar, place the ball mill jar in a planetary ball mill, and mill at a speed of 200r / min for 1h; place the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com