Pulverized coal oxygen-enriched burner meeting requirements of set deep peak load regulation, and system thereof

An oxygen-enriched combustion and pulverized coal technology, which is applied to burners, burners, combustion methods and other directions of burning powder fuel, can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

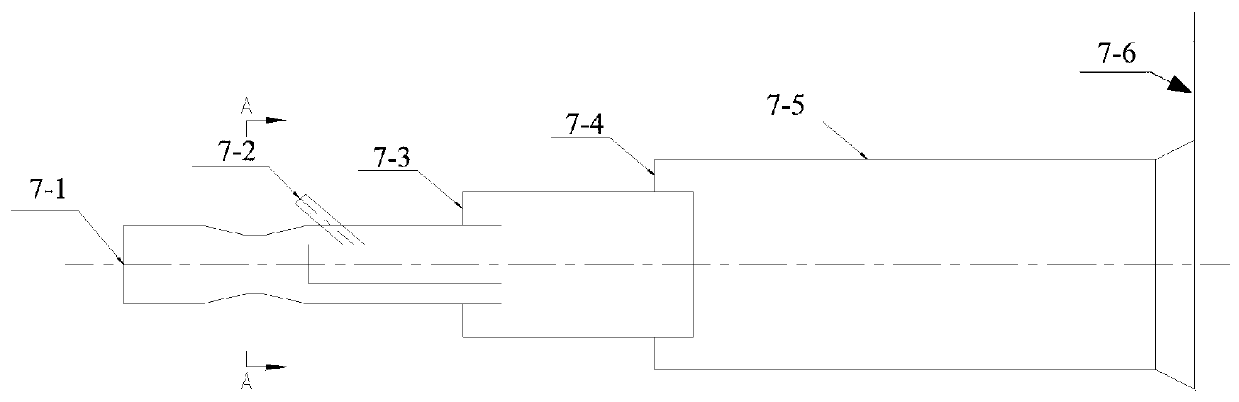

[0016] Embodiment one: if Figure 2-3 As shown, a pulverized coal oxygen-enriched burner that meets the requirements for deep peak regulation of the unit involved in this embodiment includes a primary air channel, a high-temperature oxygen channel, a secondary air channel, an overburned air channel, and a fuel mixing chamber. The chamber is connected to the water-cooled wall of the boiler, and the other side of the fuel mixing chamber is provided with a burn-off air channel, a secondary air channel is provided in the burn-out air channel, and a primary air channel and a high-temperature oxygen channel are provided in the secondary air channel. The air intake hole of the high-temperature oxygen channel protrudes from the side to the outside of the primary air channel.

[0017] The pulverized coal oxygen-enriched combustion system used to meet the requirements of deep peak regulation of the unit proposes a new type of burner that uses high-temperature oxygen-enriched gas to igni...

Embodiment 2

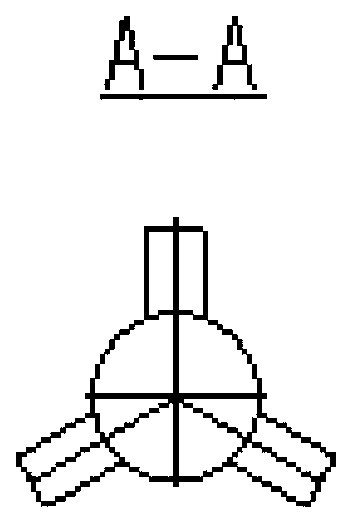

[0018] Embodiment two: if image 3 As shown, in the pulverized coal oxygen-enriched burner that meets the requirements of deep peak regulation of the unit involved in this embodiment, there are three air intake holes in the high-temperature oxygen channel.

[0019] The high-temperature oxygen-enriched gas enters the three inlets of the burner, forming a tangential swirl flow to enhance mixing.

Embodiment 3

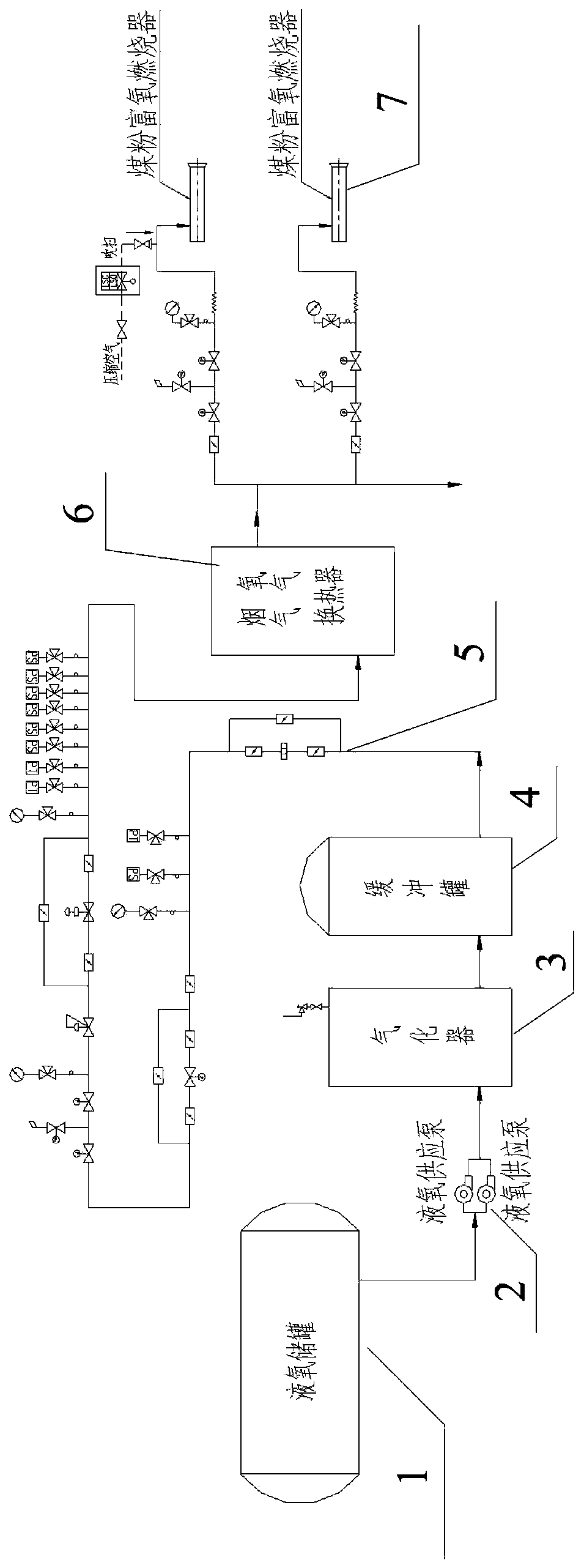

[0020] Embodiment three: as figure 1 As shown, the pulverized coal oxygen-enriched combustion system that meets the deep peak-shaving requirements of the unit involved in this embodiment includes a liquid oxygen storage tank, a liquid oxygen supply pump, a gas carburetor, buffer tank, pipeline valve, flue gas-oxygen heat exchanger and the pulverized coal oxygen-enriched burner as claimed in claim 1, the liquid oxygen is stored in the liquid oxygen storage tank, and the liquid oxygen supply pump connects the liquid oxygen storage tank The liquid oxygen in the gas is transported to the gasifier and evaporated into oxygen, and the pressure is controlled through the oxygen buffer tank. The oxygen enters the flue gas-oxygen heat exchanger through the pipeline valve to heat the oxygen, and the high-temperature oxygen enters the pulverized coal for oxygen-enriched combustion through the high-temperature oxygen channel. In the fuel mixing chamber of the burner; in the pulverized coal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com