Polyvinylidene fluoride (PVDF) thin film for single-sided frosted and high-reflection solar backplate and preparation method of PVDF thin film

A technology of solar backsheet and high reflection, which is applied in the field of optical film, can solve the problem that the solar backsheet cannot take into account EVA adhesive force and high reflectivity, etc., and achieve the effect of strong adhesive force, stable performance, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 Preparation of acrylic acid grafted polyvinylidene fluoride copolymer PVDF-g-P (AA)

[0025] Add 40mL DMF to the four-neck flask, dissolve 2g PVDF powder in the DMF solution, heat, blow nitrogen for 30min to remove air, add acrylic acid AA (mass fraction is 10%), heat in a water bath at 70°C, after 30min, add trigger Agent BPO 0.1g, reacted for 5h, after the reaction was finished, cooled at room temperature, precipitated with 50mL of absolute ethanol to remove acrylic acid homopolymer and impurities, and then vacuum dried for 24h to obtain PVDF-g-P (AA), grafting rate = (Amount of polymer after grafting-Amount of polymer before grafting) / Amount of polymer before grafting=0.8%.

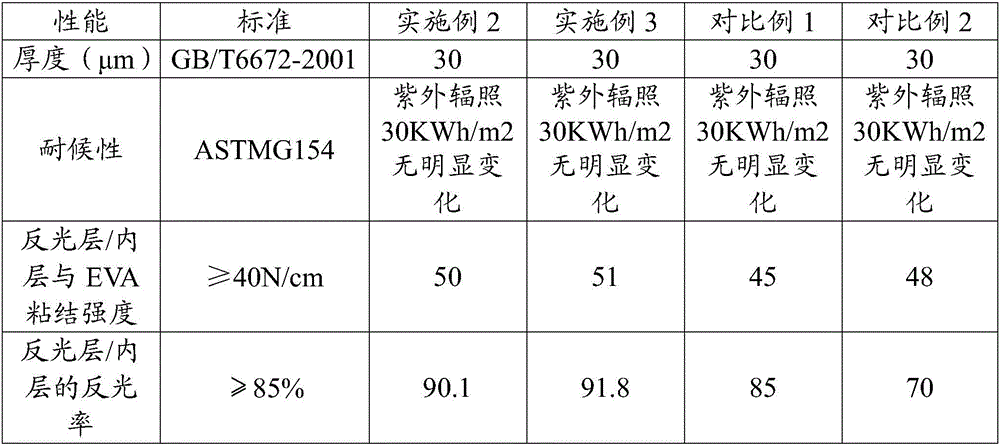

Embodiment 2

[0027] The outer layer is a frosted polyvinylidene fluoride film, and the components of the outer layer raw materials are: 1 part by weight of titanium dioxide (particle size 20 μm), 1 part by weight of silicon dioxide and 50 parts by weight of polyvinylidene fluoride resin melted blend.

[0028] The middle layer is a polymethyl methacrylate film, and the specific configuration method can refer to the existing PMMA film forming method.

[0029] The inner layer is a polyvinylidene fluoride film, and each component of the inner layer raw material is: 1 weight part of titanium dioxide (particle size: 20 μm) and 50 weight parts of polyvinylidene fluoride resin melted and blended.

[0030] The reflective layer is an acrylic modified polyvinylidene fluoride film, and each component of the reflective layer raw material is: 1 weight part of titanium dioxide (20 μm in particle size) and 50 weight parts of PVDF-g-P (AA) prepared in Example 1. blend.

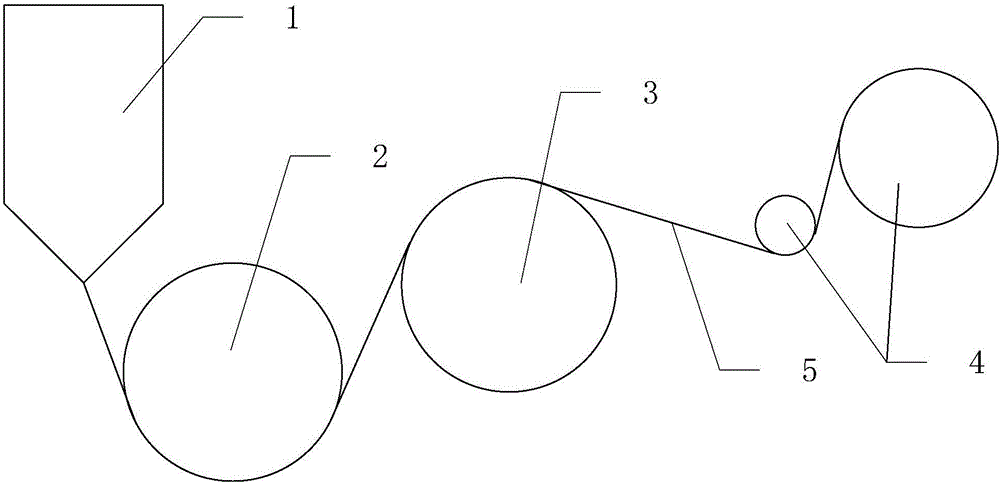

[0031] Such as figure 1 As shown...

Embodiment 3

[0038] The outer layer is a frosted surface polyvinylidene fluoride film, and the components of the outer layer raw materials are: 5 parts by weight of titanium dioxide (particle size 50 μm), 5 parts by weight of silicon dioxide and 50 parts by weight of polyvinylidene fluoride resin melt blend.

[0039] The middle layer is a polymethyl methacrylate film, and the specific configuration method can refer to the existing PMMA film forming method.

[0040] The inner layer is a polyvinylidene fluoride film, and each component of the inner layer raw material is: 5 parts by weight of titanium dioxide (particle size: 50 μm) and 50 parts by weight of polyvinylidene fluoride resin are melt blended.

[0041] The reflective layer is an acrylic modified polyvinylidene fluoride film, and each component of the reflective layer raw material is: 5 parts by weight of titanium dioxide (50 μm in particle size) and 50 parts by weight of PVDF-g-P (AA) prepared in Example 1. blend.

[0042] Such a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com