Wire type magnetic slot-wedge preparation process

A technology of magnetic slot wedge and preparation process, which is applied in the direction of manufacturing motor generators, electrical components, electromechanical devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1 The magnetic slot wedge preparation process of the present invention is sequentially divided into two steps: the preparation of the magnetic slot wedge adhesive and the forming of the iron wire type magnetic slot wedge.

[0019] The preparation process of magnetic slot wedge adhesive is as follows:

[0020] 1) Add 100 parts of epoxy resin, 8 parts of toughening agent and 2 parts of release agent zinc stearate into the stirring axe, heat the above materials to 50°C, and continue stirring for 30 minutes to process into component A.

[0021] 2) Take 100 parts of component A, then add 40 parts of curing agent pyromellitic dianhydride to component A, stir manually for 10 minutes, and finely grind the stirred material three times on a three-roller machine.

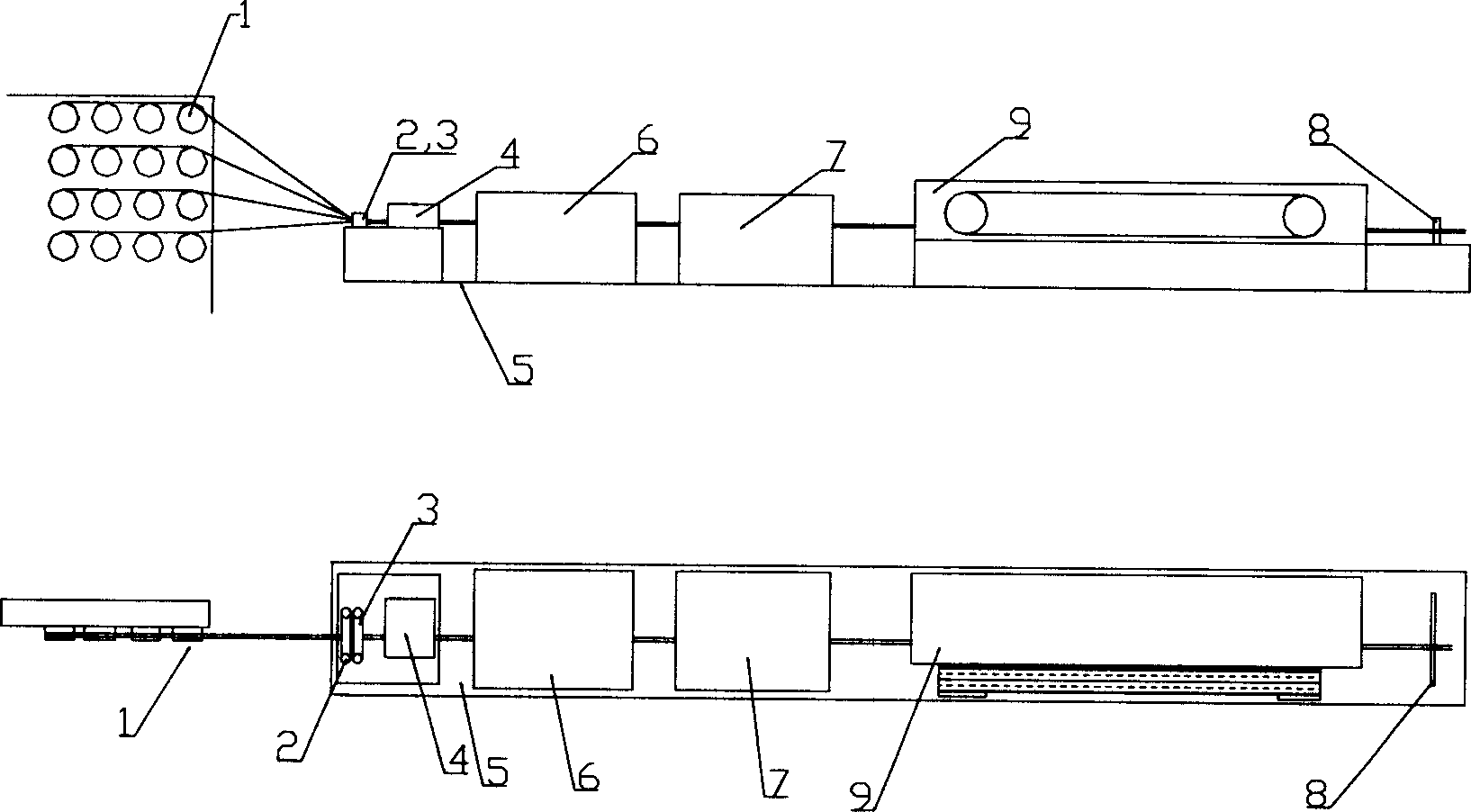

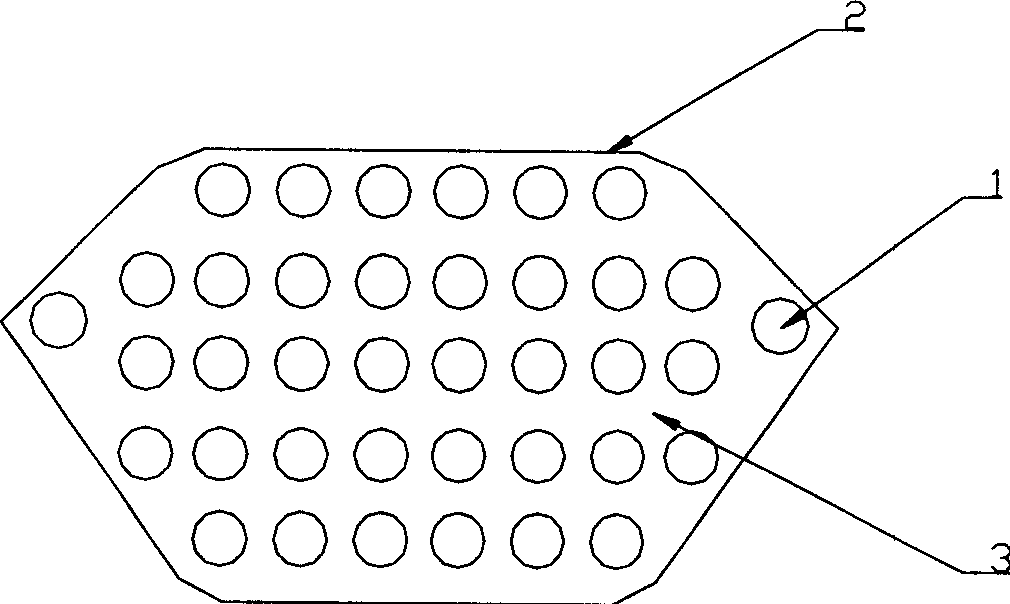

[0022] The forming process of the wire type magnetic slot wedge is as follows (see the structure of the slot wedge forming machine figure 1 ):

[0023] 1) After the galvanized iron wire is annealed, the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com