Method for producing iron ore concentrate by magnetizing and reducing limonite through biomass

A biomass raw material, limonite technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of iron ore concentrate grade difficult to reach 60%, high metal recovery rate, difficult to obtain, etc. Achieve the effect of facilitating equipment fabrication and maintenance, saving investment, and preventing sticking problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

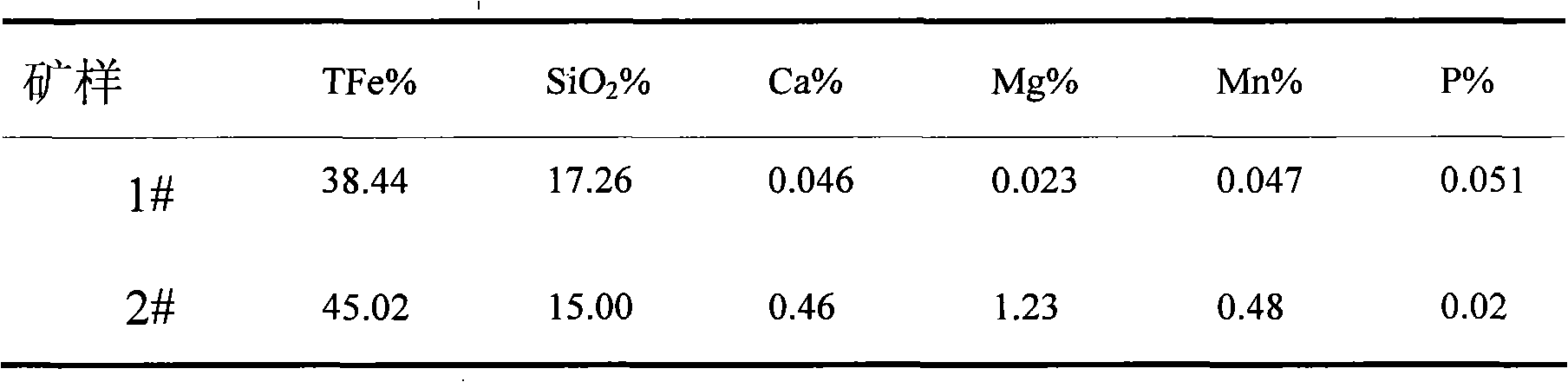

[0031] Take 200kg of poor limonite powder in Chongzuo, Guangxi (crushed to 100 mesh) and mix with 40kg of rice straw crushed to 10 mesh, and then mix evenly with 8kg of initiator additive (firewood and coal crushed to 80 mesh), and place the uniformly mixed material in the reaction In the furnace, roast at 420°C for 2 hours, cool the roasted material to below 80°C, and adopt dry magnetic separation to obtain iron concentrate with a grade of 61% and a recovery rate of 72%.

Embodiment 2

[0033] Take 200kg of lean brown ore powder in Chongzuo, Guangxi (crushed to 100 mesh), mix with 20kg of wheat straw crushed to 10 mesh and 20kg of corn stalks crushed to 10 mesh, and then mix evenly with 4kg of initiator additive (coal gangue crushed to 80 mesh), and mix well The raw material was placed in a reaction furnace and roasted at 550°C for 1 hour. The roasted raw material was cooled to below 80°C, and dry magnetic separation was used to obtain iron concentrate with a grade of 62% and a recovery rate of 75%.

Embodiment 3

[0035] Get Yunnan Qujing limonite powder 200kg (crushed to 100 mesh) and be crushed to 20 mesh 20kg sawdust and crush to 20 mesh 20kg corn stalks and mix, then mix with 4kg initiation additive (brown coal crushed to 80 mesh), mix The uniform material is placed in a reaction furnace and roasted at 500°C for 1 hour. The roasted material is cooled to below 80°C and wet magnetic separation is used to obtain iron concentrate with a grade of 65% and a recovery rate of 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com