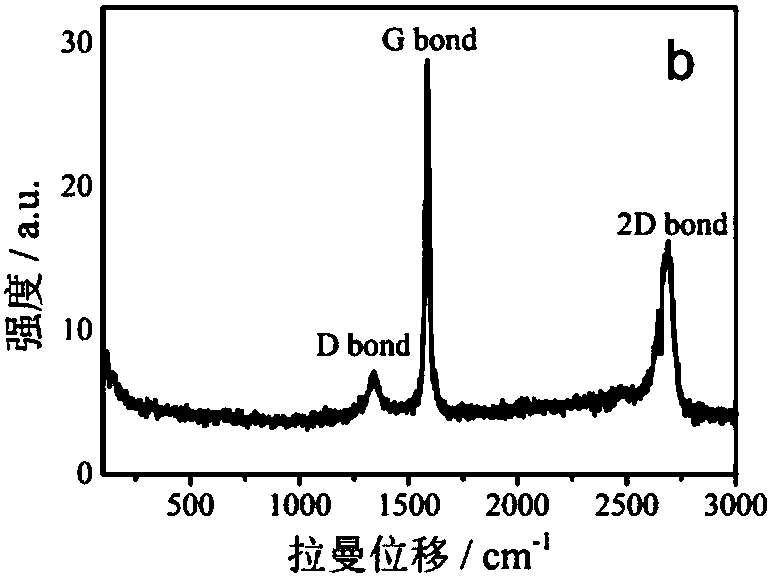

Preparation of intermediate-temperature graphene/silver composite conductive slurry and application thereof

A composite conductive and graphene technology, which can be used in equipment for manufacturing conductive/semiconducting layers, conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, etc., and can solve problems such as stable separation and dispersion. , to achieve the effect of reducing the dosage, low sintering temperature, and solving the bonding problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of preparation method of medium temperature graphene / silver composite conductive paste, comprises the following steps:

[0036] (1) Dissolve 0.5wt.% tributyl phosphate and 0.5wt.% ethyl cellulose in terpineol by magnetic stirring at 50°C;

[0037] (2) At 50°C, by magnetic stirring, add 0.5wt.% silane coupling agent, 0.5wt.% simethicone oil, 0.5wt.% dibutyl phthalate in proportion, stirring time Be 10h, obtain the organic carrier phase of this conductive paste;

[0038] (3) Weighing the organic carrier phase and placing it in a vacuum stirred tank, under a stirring condition of 100r / min, adding nano-silver powder and low-melting-point glass powder mixed uniformly in batches to obtain a mixed slurry of nano-silver; adding nano-silver powder, The ratio of the organic carrier phase to the glass powder is 30:20:2;

[0039] (4) under the stirring condition of 120r / min, take by weighing dry, activated graphene powder and place in the nano-silver mixed slurry that abov...

Embodiment 2

[0045] A kind of preparation method of medium temperature graphene / silver composite conductive paste, comprises the following steps:

[0046] (1) Dissolve 9wt.% tributyl phosphate and 9wt.% ethyl cellulose in terpineol by magnetic stirring at 100°C;

[0047] (2) Under the condition of 100 ℃, by magnetic stirring, add 4wt.% silane coupling agent, 6wt.% ethylene glycol dibutyl ether, 4wt.% dibutyl phthalate successively according to the proportion, and the stirring time is 0h, obtain the organic vehicle phase of the conductive paste;

[0048] (3) Weighing the organic carrier phase and placing it in a vacuum stirred tank, under the stirring condition of 800r / min, adding nano-silver powder and low-melting-point glass powder mixed uniformly in batches to obtain a mixed slurry of nano-silver; adding nano-silver powder, The ratio of the organic carrier phase to the glass powder is 80:75:15;

[0049] (4) under the stirring condition of 800r / min, take by weighing dry, activated graph...

Embodiment 3

[0055] A kind of preparation method of medium temperature graphene / silver composite conductive paste, comprises the following steps:

[0056] (1) Dissolve 1wt.% tributyl phosphate and 1wt.% ethyl cellulose in terpineol by magnetic stirring at 60°C;

[0057] (2) Under the condition of 60°C, by magnetic stirring, 1wt.% silane coupling agent, 1wt.% simethicone oil, 1wt.% dibutyl phthalate were added sequentially according to the proportion, and the stirring time was 12h to obtain the organic vehicle phase of the conductive paste;

[0058] (3) Take a certain amount of organic carrier phase and place it in a vacuum stirred tank. Under the condition of stirring at a low speed of 200r / min, then add uniformly mixed nano-silver powder (provided by Aladdin Reagent Co., Ltd.) and low melting point powder in batches. Glass powder, the ratio of adding nano-silver powder, organic vehicle and glass powder is 35:25:5;

[0059] (4) Under the condition of stirring at a low speed of 200r / min, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com