Controllable powder spray food 3D (three-dimensional) printing equipment and method

A 3D printing and powder spraying technology, which is applied in the field of controllable powder spraying food 3D printing equipment and printing, can solve the problems of slow development of printing and slow development of food graphics appearance processing technology, so as to improve printing efficiency and improve adhesion and firmness. degree, the effect of expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings.

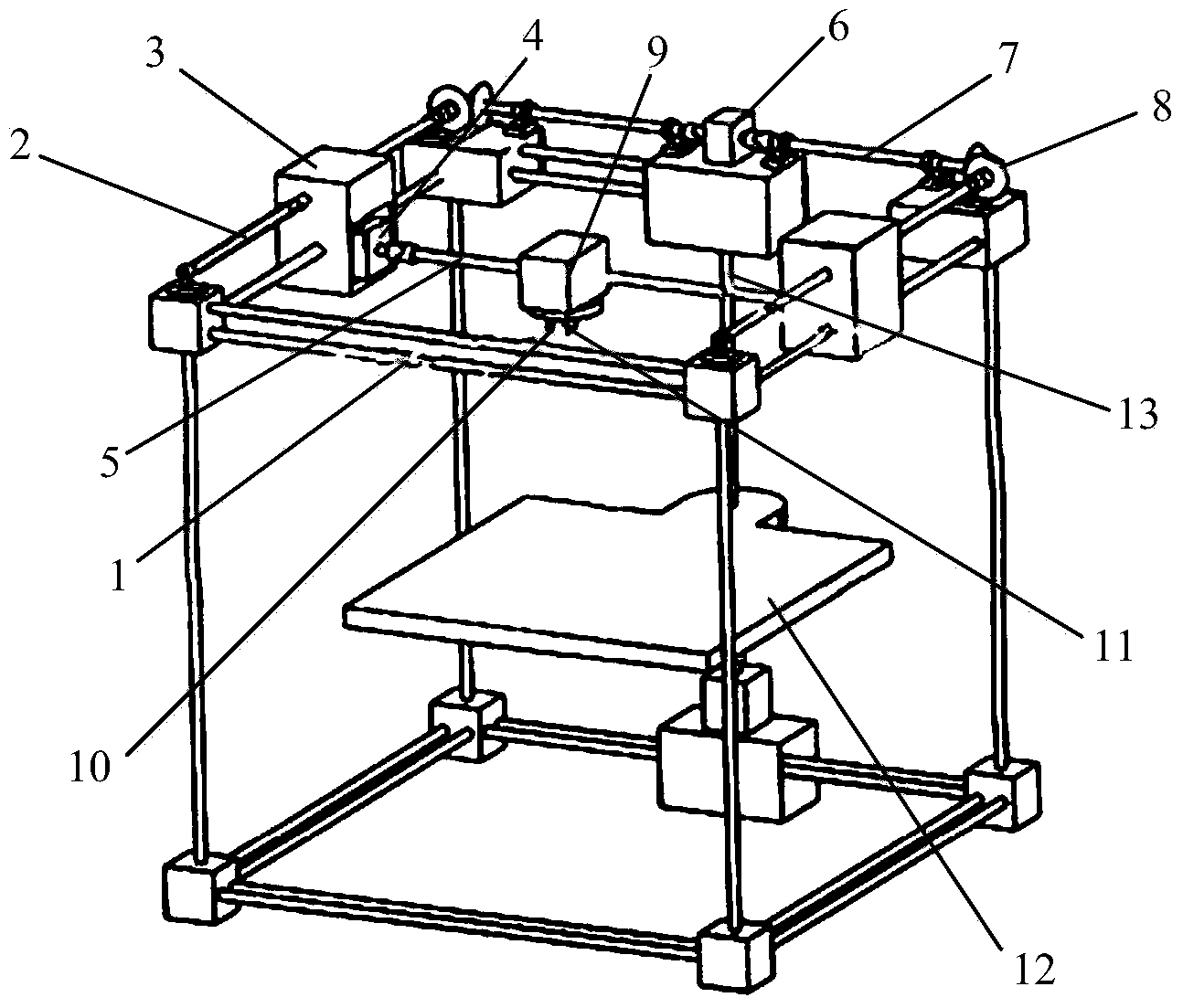

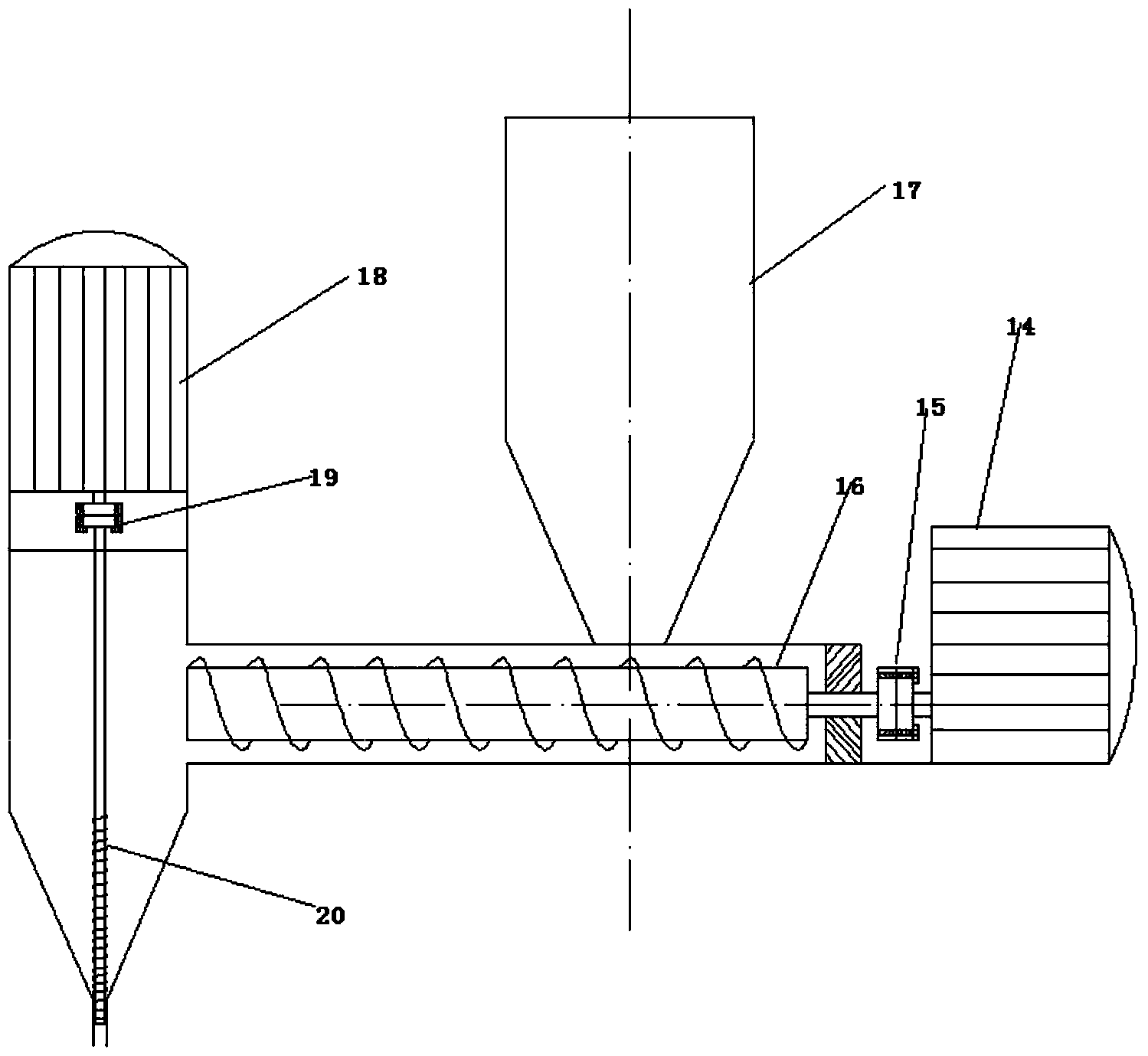

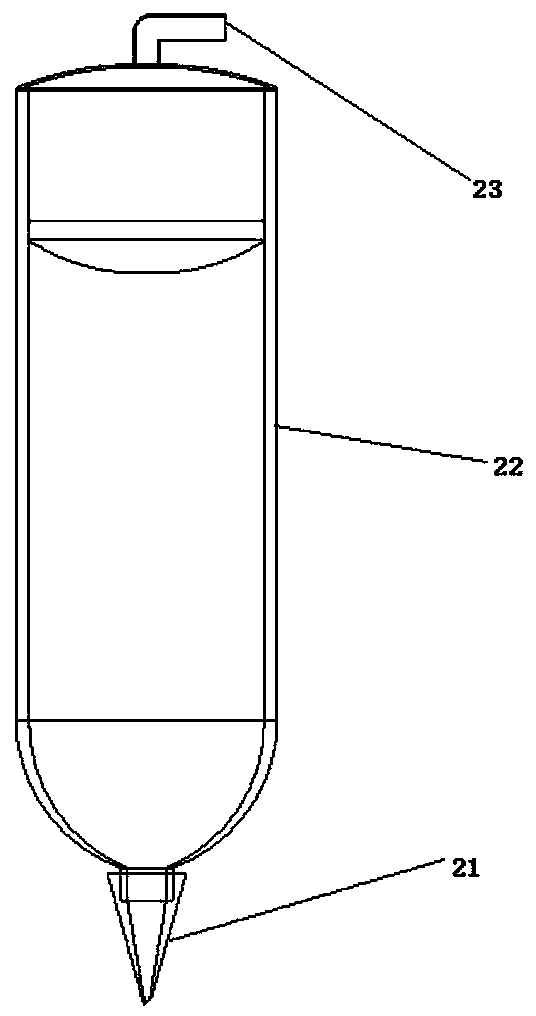

[0040] see Figure 1 to Figure 5 , a controllable powder spraying type food 3D printing equipment of the present invention, comprising a support frame 1, a three-dimensional positioning device is installed on the support frame 1, and a casing for protecting the internal structure of the support frame 1 is also provided on the periphery of the support frame 1, the machine The shell is made of glass material; the base plate 12 is made of plated alloy material; five nozzles 11 are fixedly installed on the rotary connection disc 10 . In the three-dimensional positioning device, the X-axis positioning device and the Y-axis positioning device are installed on the top of the support frame, and the Z-axis positioning device is installed on the side of the support frame; the X-axis positioning device is equipped with a rotating device for spraying powder food and liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com