Blend fibers of alginate and sodium carboxymethyl cellulose and preparation method and application thereof

A technology of sodium carboxymethyl cellulose and blending fibers, applied in the field of fibers, can solve problems such as serious bonding and inconvenience in weaving, and achieve the effects of improving deficiencies, excellent hygroscopicity and physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

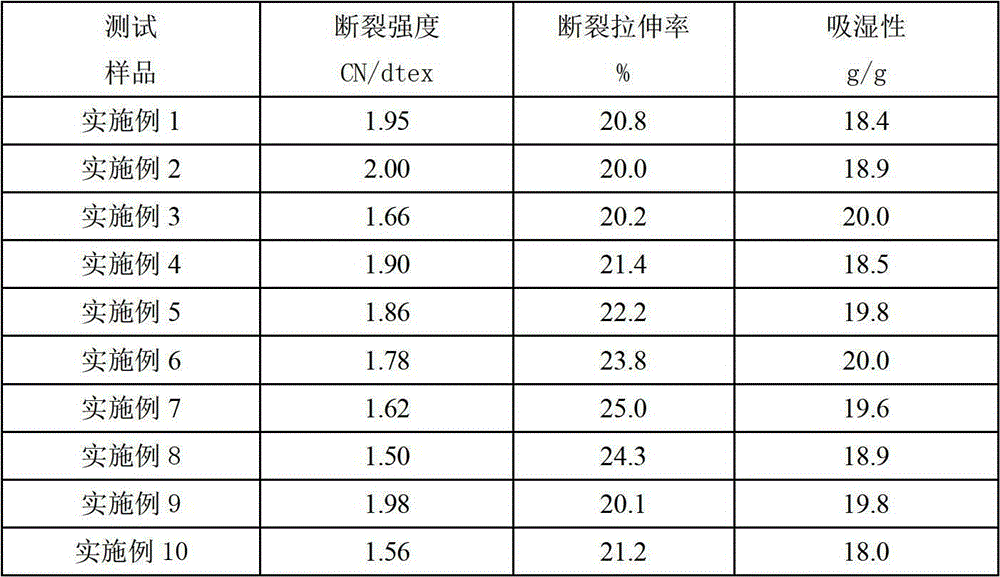

Examples

preparation example Construction

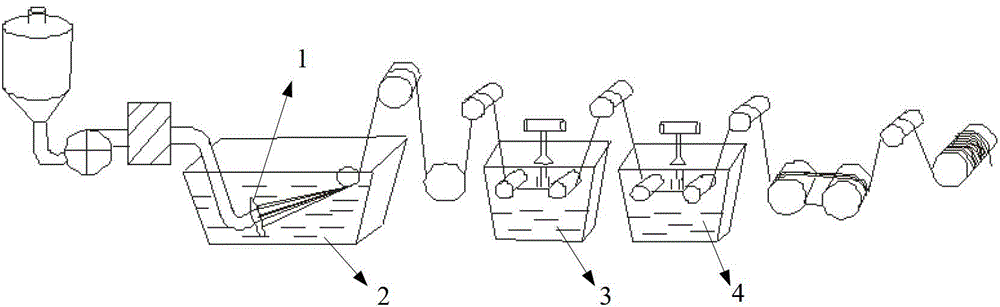

[0034] Specifically, the above-mentioned preparation method mainly includes: configuring sodium alginate-CMCNA blended spinning solution; passing the blended spinning solution through a spinning pump and a filter and then entering the spinneret; The flow enters the coagulation bath to form primary mixed fibers, and then the blended fibers of alginate and CMCNA fibers are obtained after stretching, washing, splitting, drying, winding and other processes.

[0035] Specifically, in the above sodium alginate-CMCNA blended spinning solution, the mass ratio of sodium alginate to CMCNA is 3-19:1, preferably, the mass ratio of sodium alginate to CMCNA is 9-19:1. The mass percentage of sodium alginate in the above sodium alginate-CMCNA blended spinning solution is 2%-8%, preferably 3%-5%. The M / G ratio in the above sodium alginate is greater than 1. Further preferably, the M / G ratio is 1.5-1.8. Among them, the M / G ratio is the content ratio of the M unit to the G unit in sodium algin...

Embodiment 1

[0041] Select sodium alginate with a mass ratio of 95:5 and mix it with CMCNA powder, wherein the M / G ratio of sodium alginate is 1.5. The mixed powder was placed in a dissolution tank, and a certain amount of warm distilled water was added to prepare a mixed solution, the mass fraction of sodium alginate in the mixed solution was 3%. Add distilled water while stirring, so that sodium alginate and CMCNA powder are fully dissolved in distilled water and mixed evenly. When the mixed solution becomes clear and transparent, filter it, and then vacuum defoam for 24 hours to prepare uniform sodium alginate-CMCNA co- Blended silk solution A.

[0042] Using wet spinning process, such as figure 1 As shown, the above-mentioned sodium alginate-CMCNA blended spinning solution A is filtered through a spinning pump and a filter, then enters the spinneret 1, and then is pressed out from the spinneret hole to form a thin stream of stock solution, which enters the 35°C In the calcium chlorid...

Embodiment 2

[0045] The mass fraction of sodium alginate in the mixed solution in Example 1 was changed to 5%, and other conditions and steps were basically the same as in Example 1, and the blended fiber B of alginate and CMCNA was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Performance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com