Solid insulation complete enclosed switch isolation cover

A solid insulation and fully sealed technology, which is applied to the board/panel/desk of the substation/switchgear, etc., can solve the problems that cannot be installed in the miniaturized switchgear, and the volume is large, so as to meet the size requirements, enhance the insulation level, reduce the The effect of small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

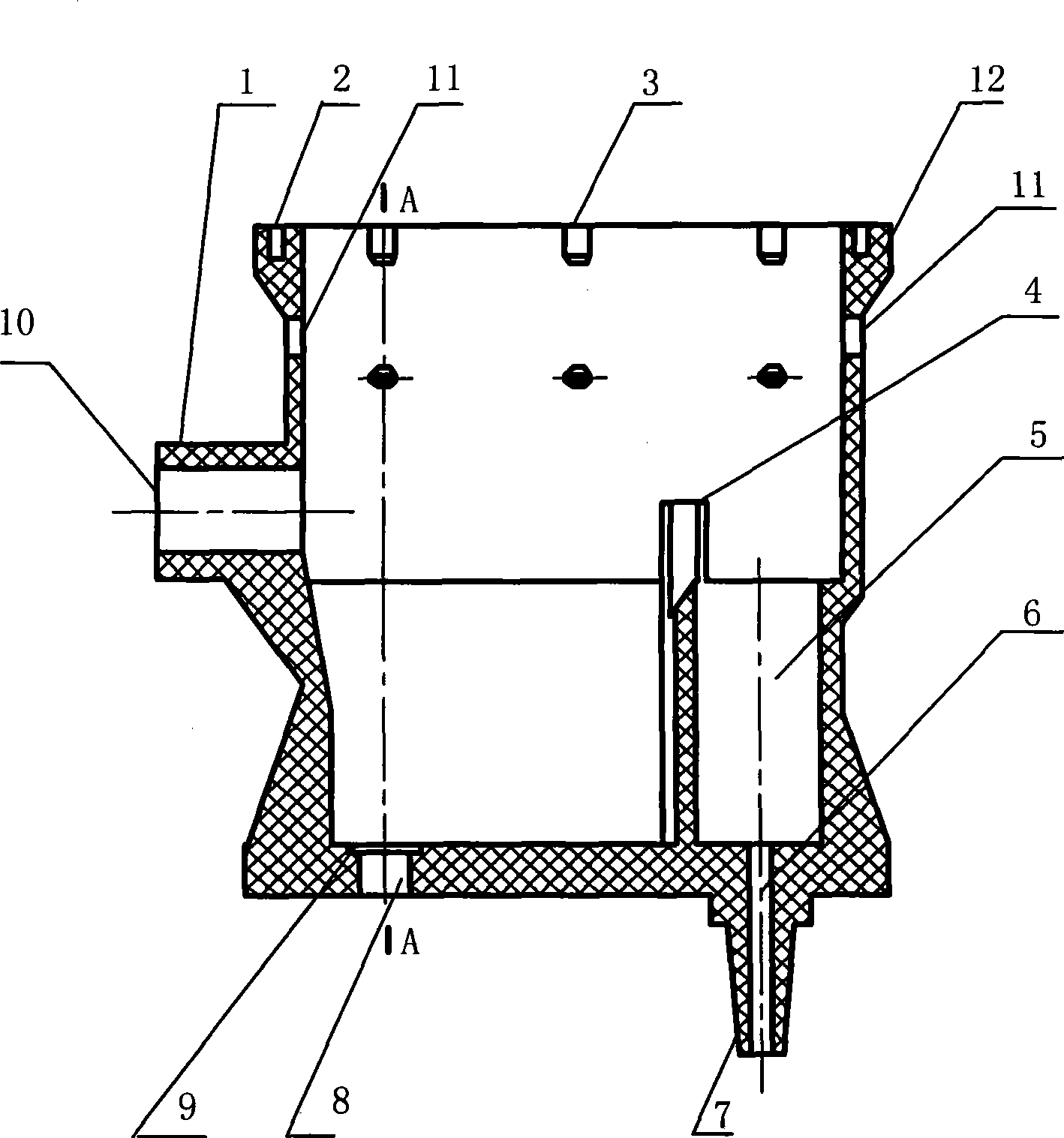

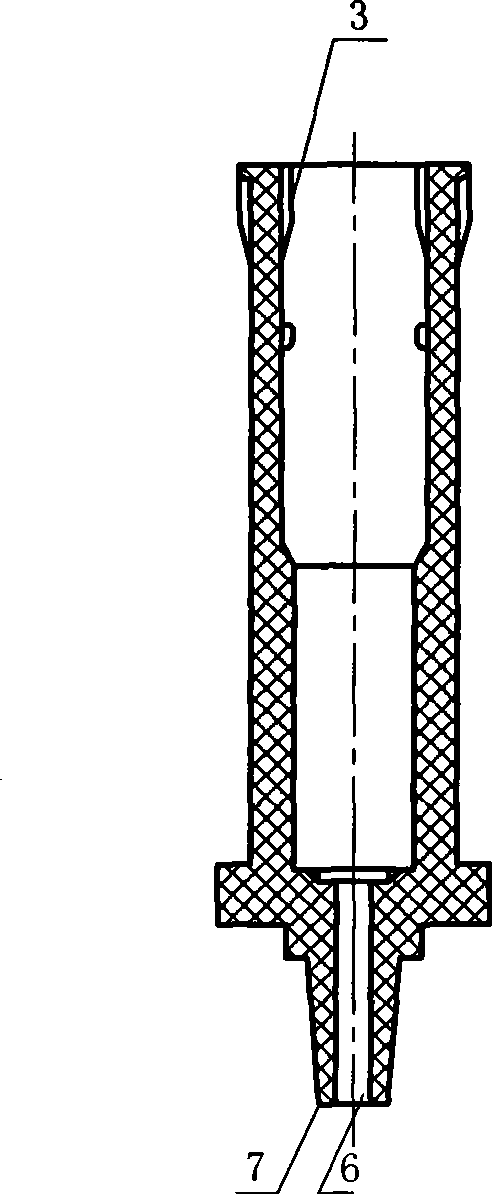

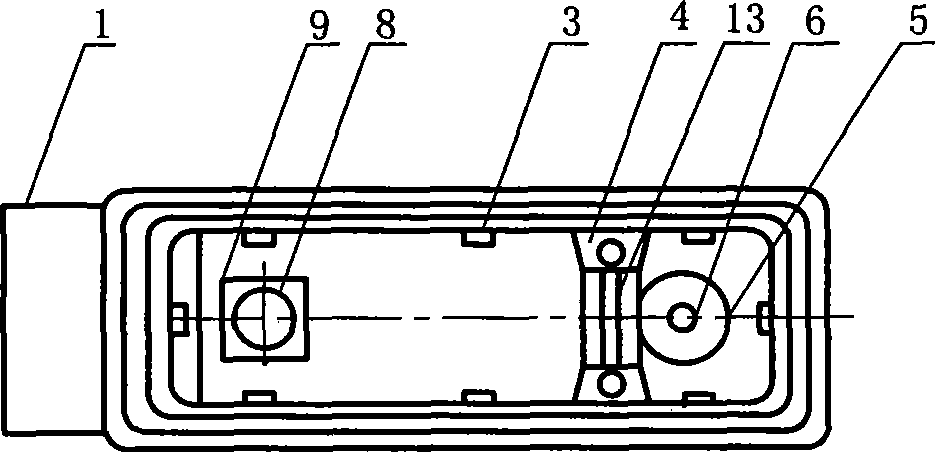

[0018] like Figure 1 to Figure 3 As shown, a solid insulating fully sealed switch insulating cover of the present invention, the solid insulating fully sealed switch insulating cover is made of integral casting of epoxy resin. The solid insulation fully sealed switch insulation cover 10 is a long tube with a rectangular cross section. There is a large boss 1 on one side of the long tube. There is a double-pass bushing hole 10 inside the big boss 1. The double-pass bushing hole 10 communicates with the inside of the solid insulation full-sealed switch insulation cover, and is used to install the double-pass bushing. There is an observation hole 11 on the long tube above the large boss 1, and there is also an observation hole 11 at the opposite symmetrical position, which is convenient for the user to observe the solid state. The movement state of the parts in the insulation cover of the fully insulated switch. Have a grounding contact head hole 8 on the bottom surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com