Polymer micro-channel machining method based on space-time shaping femtosecond laser

A femtosecond laser and processing method technology, applied in the field of laser applications, can solve the problems of insufficient micro-nano manufacturing of space-time shaping technology, poor micro-channel structure quality and reachable depth, and horizontal and vertical asymmetry of processing results, etc., to improve Repeatability and quality, improving detection efficiency and stability, and meeting dimensional requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

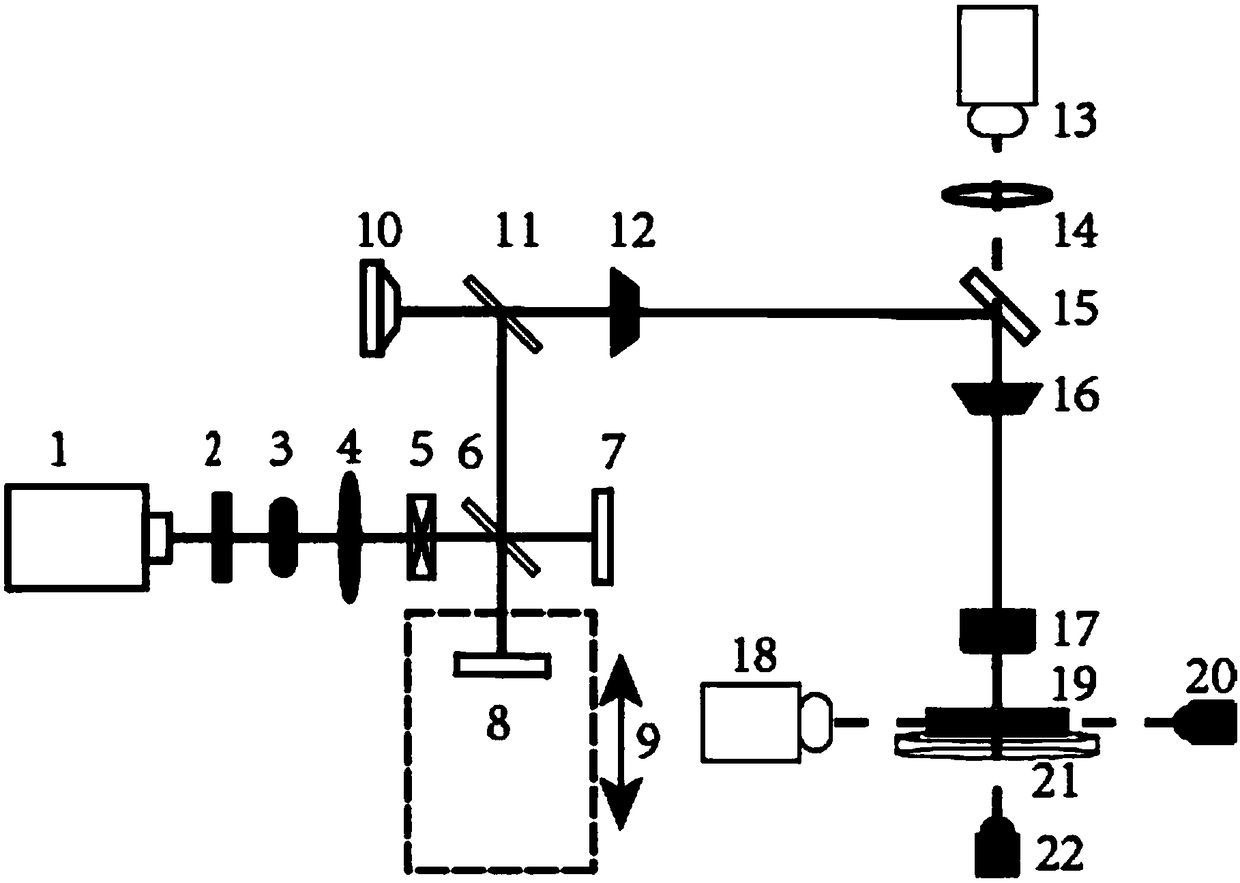

[0023] Example 1: Taking the longitudinal processing of gelatin with a spatiotemporal shaping double-pulse femtosecond laser sequence to obtain a microchannel structure as an example. The main equipment and raw materials involved in this embodiment are as follows:

[0024] The femtosecond laser is Coherent's titanium sapphire laser, with a center wavelength of 800nm, a pulse width of 35fs, a repetition rate of up to 1000Hz, a maximum single pulse energy of 7mJ, and a Gaussian distribution of light field.

[0025] The spatial light modulator (SLM) is the Pluto-2 model of Holoeye Company.

[0026] The raw material of gelatin is the raw material of Aladdin bottle.

[0027] The specific processing steps of the present embodiment are as follows:

[0028] Step 1, prepare gelatin base sample: weigh 3.35g of gelatin particles, weigh 46.65ml of deionized water as a dispersion medium, mix the two to prepare a gelatin aqueous solution, heat at 70°C for 30 minutes, and wait until the ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com