Assembling type embedded beam-column joint structure

A beam-column node and node structure technology, which is applied in building construction, construction, etc., can solve the problems that beam-column nodes cannot realize industrialized mass production, complicated on-site installation and construction procedures, etc., and achieves convenient processing and manufacturing, flexible use conditions, and safety. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention will be further described:

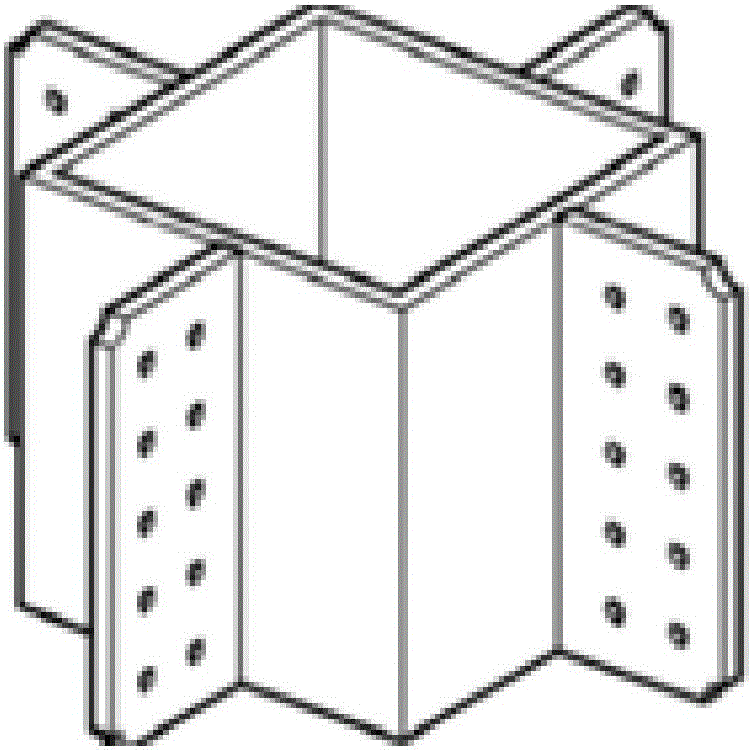

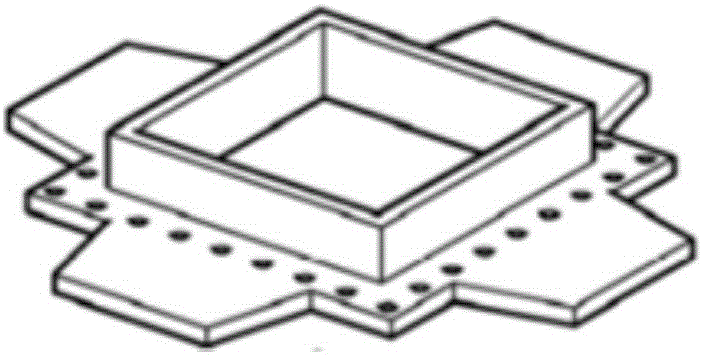

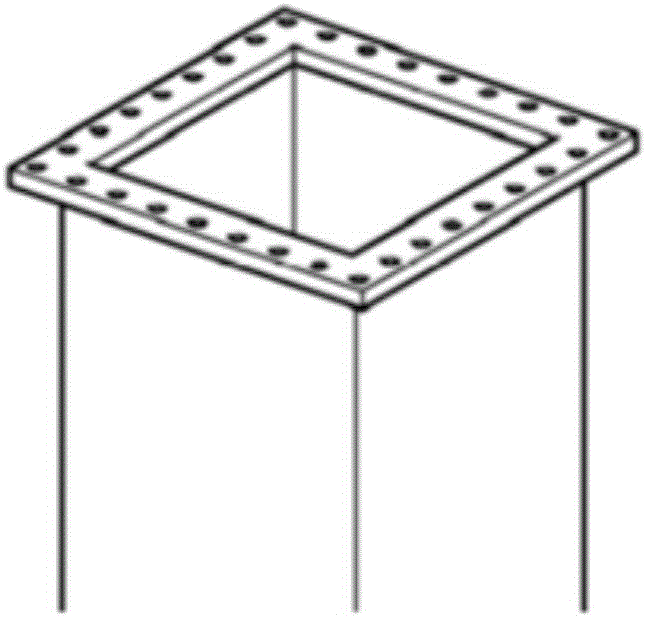

[0022] Such as Figure 1-1 to Figure 1-4 , figure 2 and image 3 As shown, an assembled embedded beam-column node structure can connect the steel column 2 and the steel beam 3 into a whole through high-strength bolts. The outer walls are respectively protrudingly provided with connecting plates 1a, and correspondingly provided on the steel beam 3 are convex plates 3a connected with the connecting plates 1a. In this embodiment, two rows of bolts are correspondingly provided on the connecting plates 1a and the convex plates 3a. hole;

[0023] The upper and lower ends of the core piece 1 are symmetrically provided with connecting pieces 4 for connecting the steel columns 2. In this embodiment, there is a weld seam between the core piece 1 and the connecting pieces 4 and they are connected by a welding process. A flange 4a fitted with a groove of the steel column 2 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com