Method for preparing graphene-based support membrane of transmission electron microscope grid by directly etching metal substrate

A metal substrate, transmission electron microscope technology, applied in the direction of material analysis, instruments, measurement devices, etc. using wave/particle radiation, can solve the problems of difficulty in obtaining single-layer or even few-layer graphene support films, difficulty in batch preparation, and high cost , to achieve the effect of high integrity, avoiding transfer process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

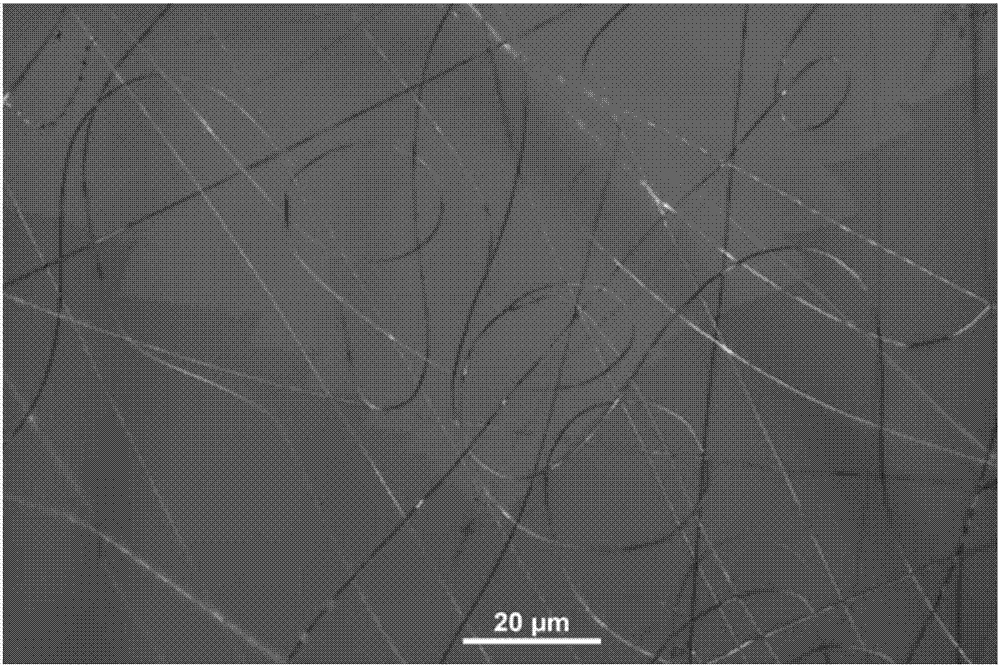

[0078] Example 1. Direct etching of copper foil substrate to produce graphene transmission net support film

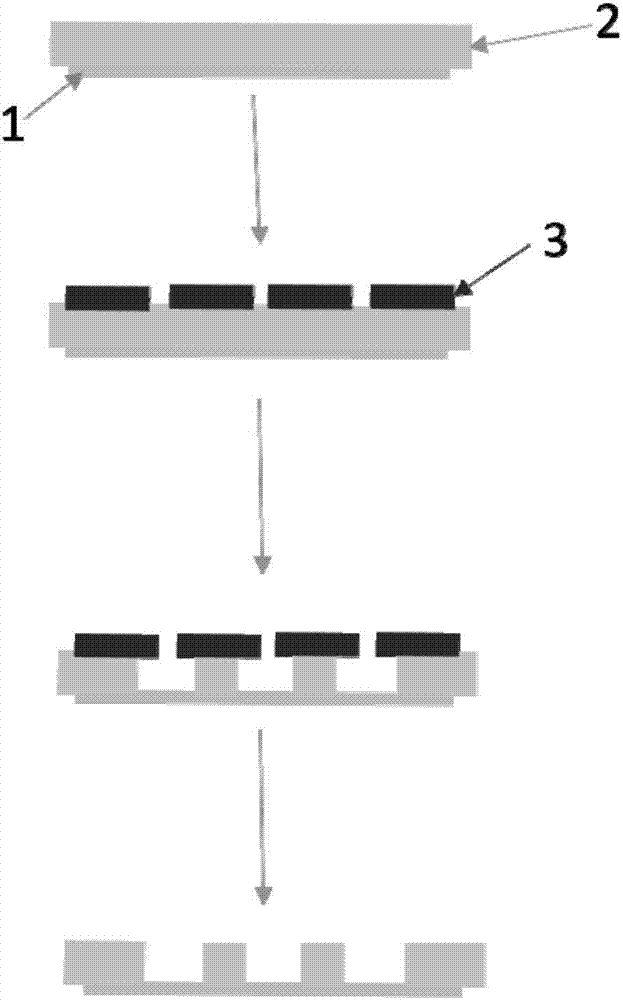

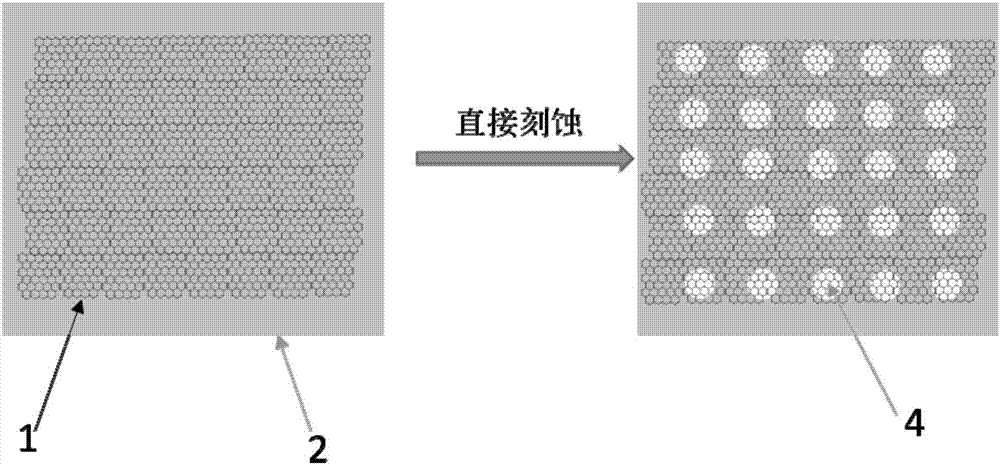

[0079] Such as figure 1 Shown is a schematic flow diagram of the preparation method of the present invention, such as figure 2 Shown is the overall concept of the preparation method of the present invention. The specific implementation process is as follows:

[0080] 1) The growth of graphene on a copper foil substrate uses a low pressure chemical vapor deposition system (LPCVD). The copper foil (purity 99.8%, thickness 25mm) is annealed in a hydrogen atmosphere for 30 minutes at 1000℃, the hydrogen flow rate is 300sccm, the system pressure is maintained at 350Pa, and then annealed in an argon atmosphere for 30 minutes, the argon flow rate is 500sccm , The system pressure is maintained at 500Pa. The effect of annealing under hydrogen atmosphere is to reduce the oxide layer on the surface of the copper foil, and the effect of annealing under argon atmosphere is to reduce ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com