Taper conformal omnidirectional double-frequency micro-strip antenna array

A technology of microstrip antenna and microstrip feeder, which is applied in the direction of antenna arrays, antenna arrays powered on separately, antennas, etc., can solve the problems of large area occupied by antenna arrays, difficult design, small antenna size, etc., so that it is not easy to break, Not prone to cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

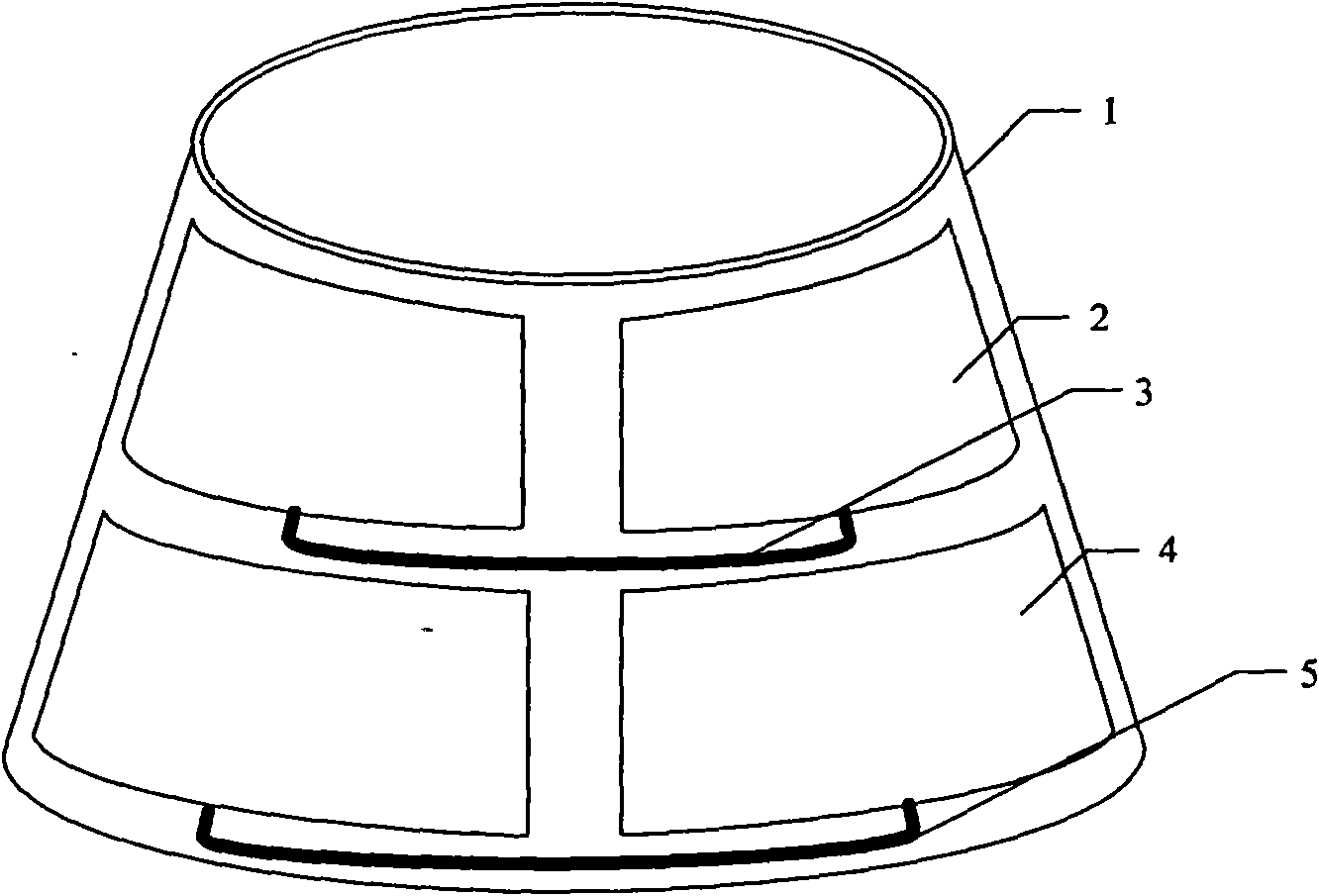

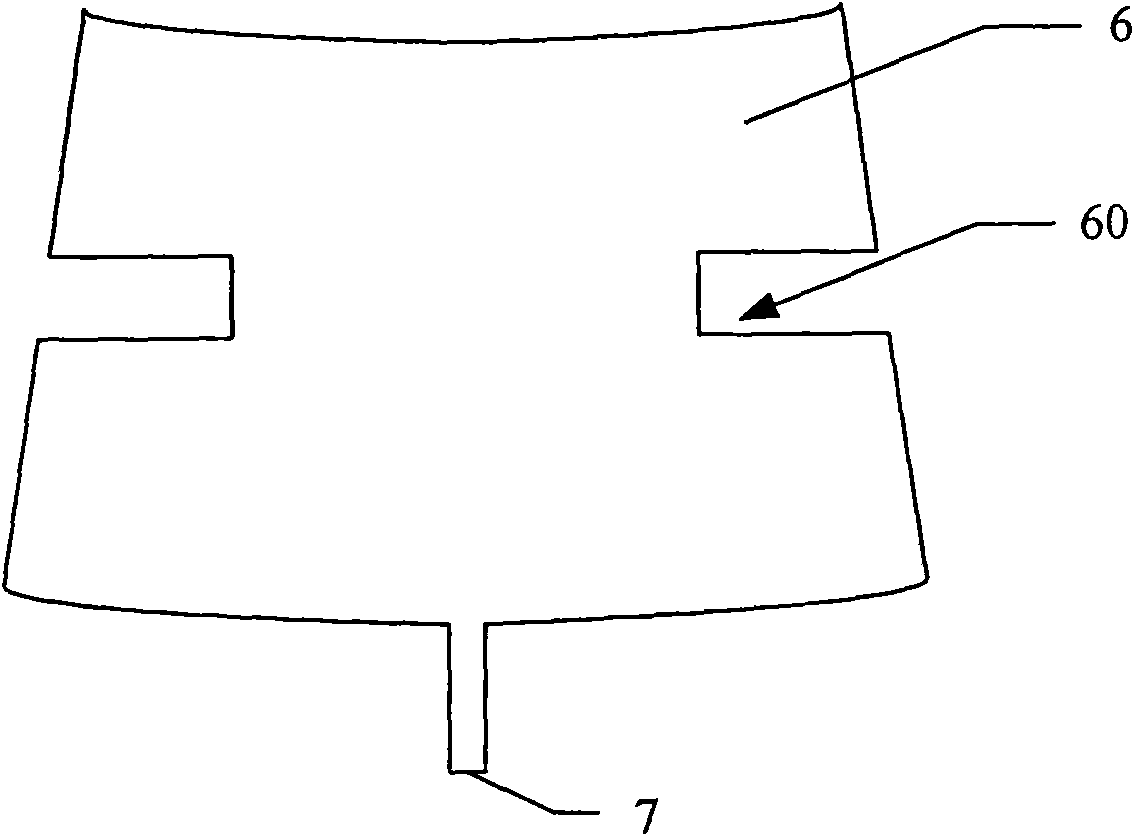

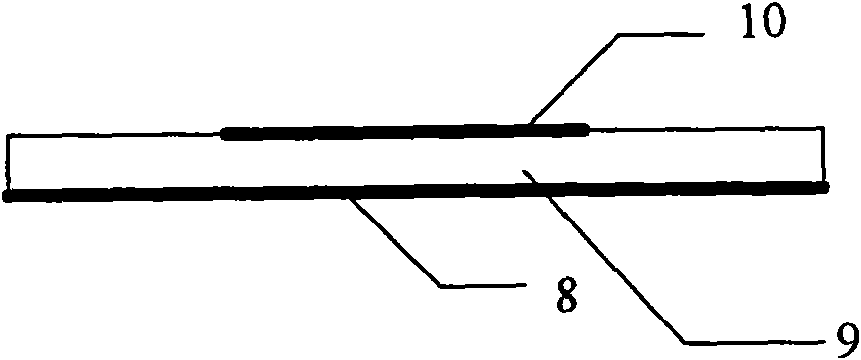

[0032] combine figure 1 , Figure 6 , a conical conformal omnidirectional dual-frequency microstrip antenna array, the surface of the cone surrounding the conical carrier 1 is provided with a high-frequency microstrip antenna array 2 and a low-frequency microstrip antenna array 4 that are arranged up and down and are conformal to the conical carrier 1 , the high-frequency microstrip antenna array 2 is close to the cone top of the conical carrier 1, and the low-frequency microstrip antenna array 4 is arranged below the high-frequency microstrip antenna array 2; the high-frequency microstrip antenna array 2 is connected by several parallel feeders. The low-frequency microstrip antenna array 4 is composed of several low-frequency microstrip antenna units 11 connected in parallel feed.

[0033] The high-frequency microstrip antenna unit 6 is connected in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com