High-doped erbium intermediate infrared tellurium germinate glass and preparation method thereof

A tellurium-germanate and infrared technology is applied in glass manufacturing equipment, glass molding, manufacturing tools and other directions, which can solve problems such as differential thermal stability, and achieve the effects of improved luminous intensity, low production cost and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

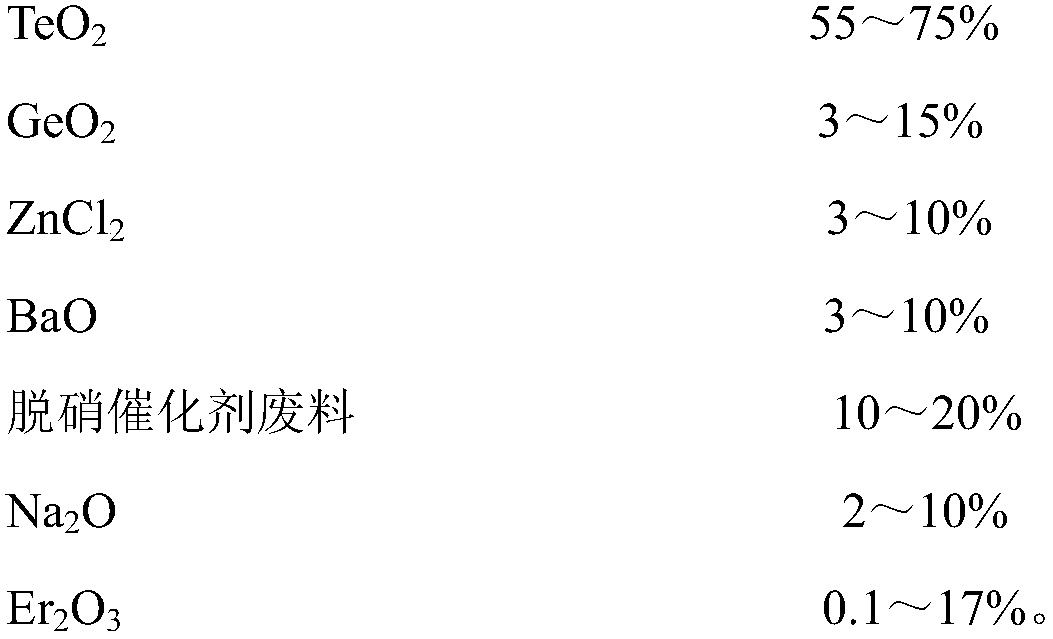

[0022] Embodiment 1: a kind of tellurite glass;

[0023] A kind of tellurate glass, raw material composition is as shown in 1# in table 1;

[0024] According to the mass percent of 1# glass composition in Table 1, calculate the corresponding weight of each composition, and take by weighing each raw material component;

[0025] Grind the raw materials evenly to form a mixture, put it into a gold crucible, and place it in a silicon carbide rod electric furnace at 980 ° C for 30 minutes to obtain molten glass. During the glass melting process, high-purity oxygen is always introduced into the atmosphere Protected to remove moisture from the molten glass. The glass liquid from which moisture has been removed is homogenized and clarified, and then quickly poured onto a mold preheated to 370°C, and then placed in a muffle furnace heated to 370°C, which has been heated to the glass liquid, and kept for 3 hours, then Cool down to 110°C at a rate of 11°C / hour, then close the muffle fu...

Embodiment 2

[0030] Embodiment 2: a kind of germanate tellurite glass;

[0031] A kind of germanate tellurite glass, the composition of raw materials is as shown in 2# in Table 1;

[0032] According to the mass percentage that 2# glass forms among the table 1, calculate the corresponding weight of each composition, and take each raw material component;

[0033] Grind the raw materials evenly to form a mixture, put it into a gold crucible, and place it in a silicon carbide rod electric furnace at 900 ° C for 30 minutes to obtain molten glass. During the glass melting process, high-purity oxygen is always introduced into the atmosphere Protected to remove moisture from the molten glass. The dehydrated glass liquid is homogenized and clarified, then quickly poured onto the mold that has been preheated to 450°C, and then put into the muffle furnace that has been heated to 460°C. The temperature was lowered to 110° C., then the muffle furnace was closed, and the temperature was lowered to roo...

Embodiment 3

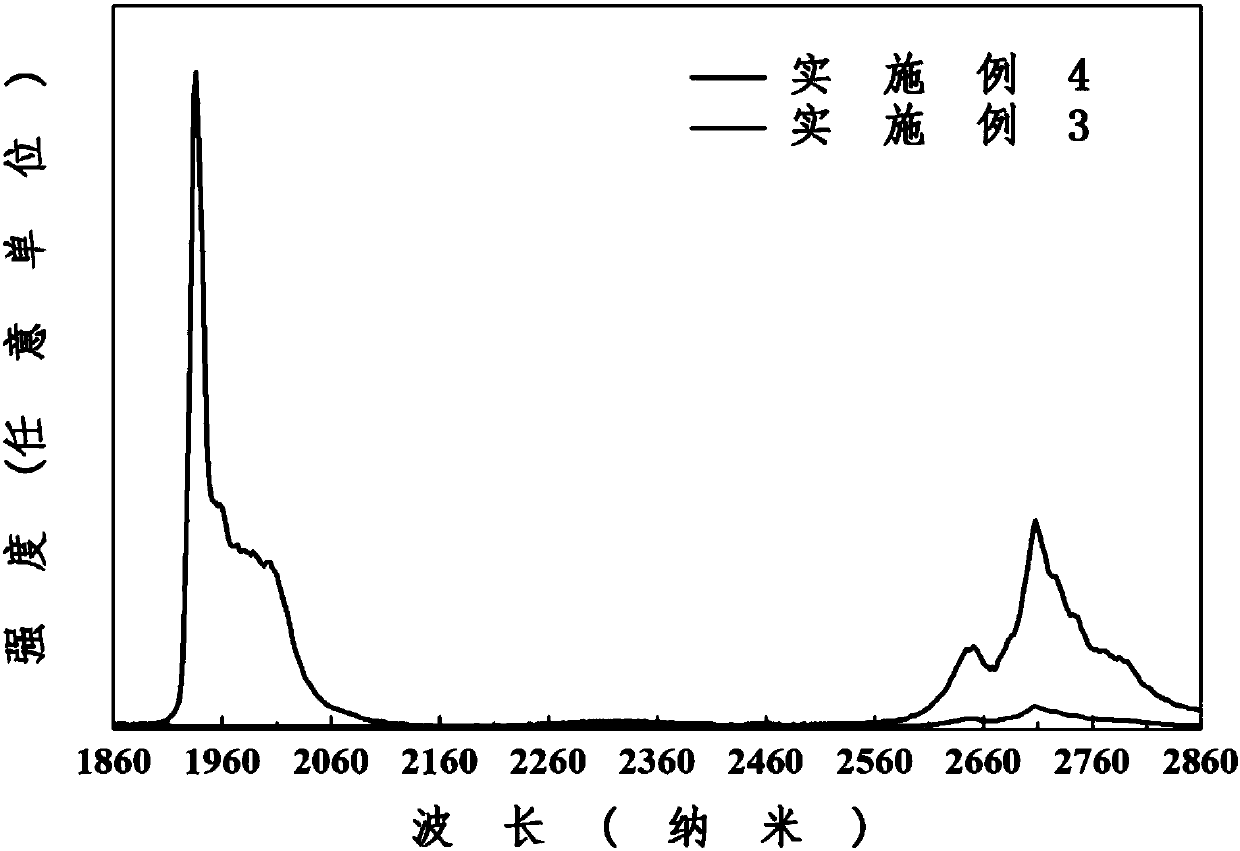

[0038] Embodiment 3: a kind of erbium-doped tellurium germanate glass;

[0039] A kind of erbium doped tellurium germanate glass, raw material composition is as shown in 3# in table 1;

[0040] According to the mass percent that 3# glass forms among the table 1, calculate the corresponding weight of each composition, and take each raw material component;

[0041] Grind the raw materials evenly to form a mixture, put it into a gold crucible, and place it in a silicon carbide rod electric furnace at 900 ° C for 30 minutes to obtain molten glass. During the glass melting process, high-purity oxygen is always introduced into the atmosphere Protected to remove moisture from the molten glass. The dehydrated glass liquid is homogenized and clarified, then quickly poured onto the mold that has been preheated to 460°C, and then put into the muffle furnace that has been heated to 460°C. The temperature was lowered to 110° C., then the muffle furnace was closed, and the temperature was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com