Preparation method of Si-B-C-N (silicon-boron-carbon-nitrogen) ceramic with PBSZ (polyborosilazane) as additive

A polysilaborazane and silicon boron carbonitride technology, which is applied in the field of preparation of silicon boron carbonitride ceramics, and can solve the problems of difficult sintering and dense materials, unfavorable high temperature performance of materials, and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

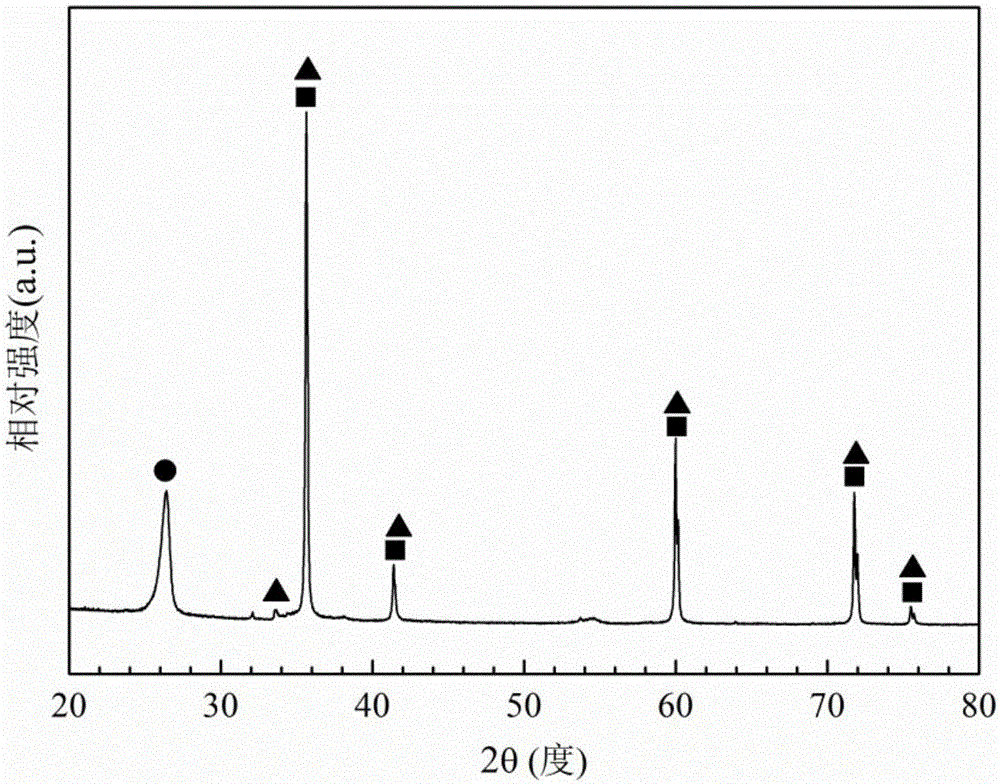

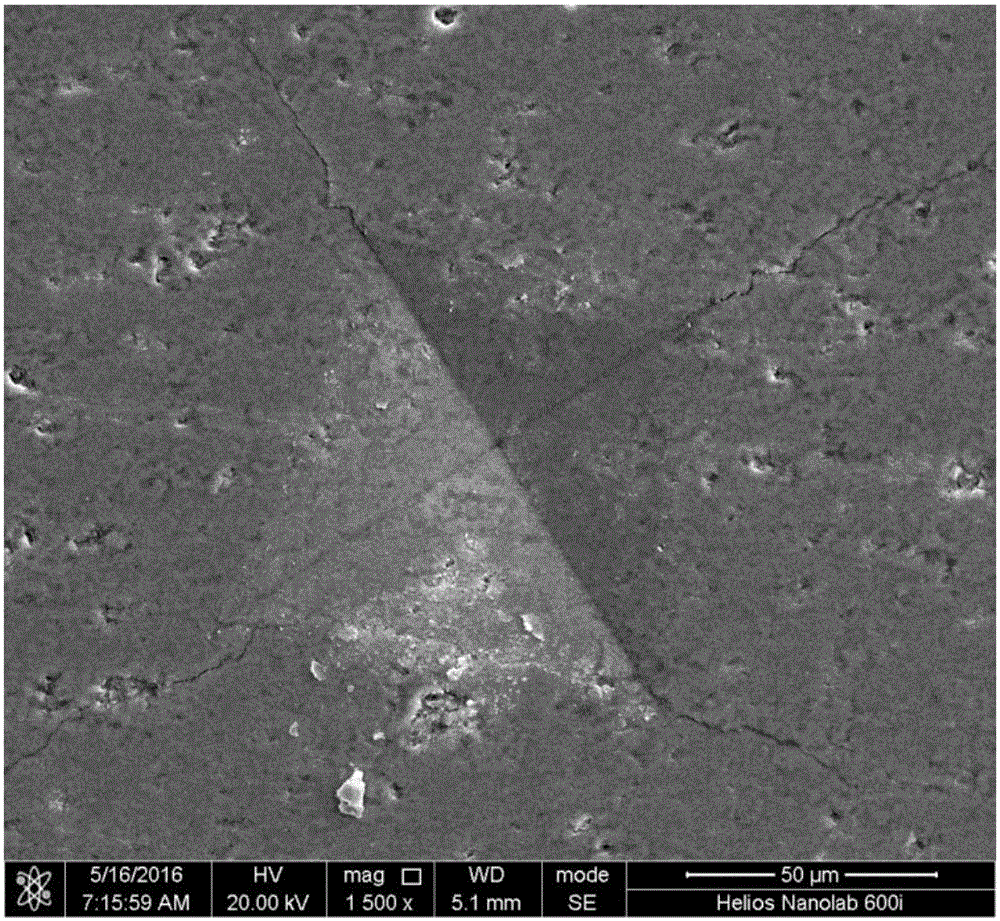

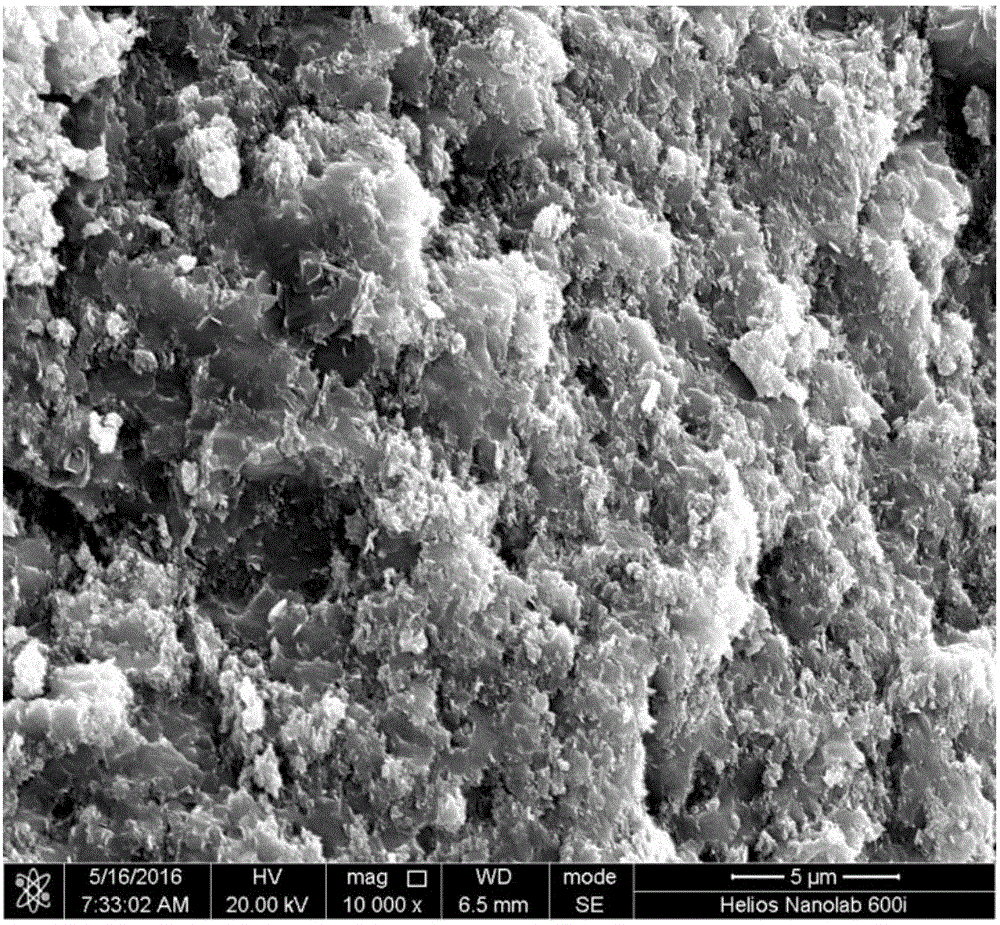

[0023] The preparation method of a kind of silicon boron carbon nitrogen ceramics that uses polysilaborazane as an additive involved in this embodiment is specifically carried out in accordance with the following steps: 1. According to the Si:B:C:N molar ratio of 2:1:3 Cubic silicon powder, hexagonal boron nitride powder and graphite powder are weighed in a ratio of 1; the silicon powder has a purity of 99% to 99.9% and a particle size of 1 to 20 μm; the graphite powder has a purity of 99% to 99.9% and a particle size of 1~20μm; the purity of boron nitride powder is 99%~99.9%, and the particle size is 1~20μm; 2. Put the weighed raw materials into a ball mill jar, and perform high-energy ball milling under the protection of argon atmosphere to obtain amorphous Si- B-C-N ceramic powder; wherein the mass ratio of the ball to material is 40:1, the diameter of the ball is 8mm, and the ball milling time is 25h; 3. Mix the amorphous Si-B-C-N ceramic powder obtained in step 2 with PBSZ...

Embodiment 2

[0027] The preparation method of a kind of silicon boron carbon nitrogen ceramics that uses polysilaborazane as an additive involved in this embodiment is specifically carried out in accordance with the following steps: 1. According to the Si:B:C:N molar ratio of 2:1:3 Cubic silicon powder, hexagonal boron nitride powder and graphite powder are weighed in a ratio of 1; the purity of cubic silicon powder is 99% to 99.9%, and the particle size is 1 to 20 μm; the purity of graphite powder is 99% to 99.9%. The particle size is 1-20 μm; the purity of the hexagonal boron nitride powder is 99%-99.9%, and the particle size is 1-20 μm; 2. Put the weighed raw materials into a ball mill jar, and perform high-energy ball milling under the protection of an argon atmosphere Obtain amorphous Si-B-C-N ceramic powder; wherein the mass ratio of ball to material is 35:1, the diameter of the ball is 8mm, and the ball milling time is 30h; three, the amorphous Si-B-C-N ceramic powder obtained in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com