Integral conical pick and method for producing the same

An integrated, conical technology, used in earth-moving drilling, cutting machinery, improving energy efficiency, etc., can solve the problems of reduced service life and low hardness, and achieve the effect of improving service life, high hardness and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

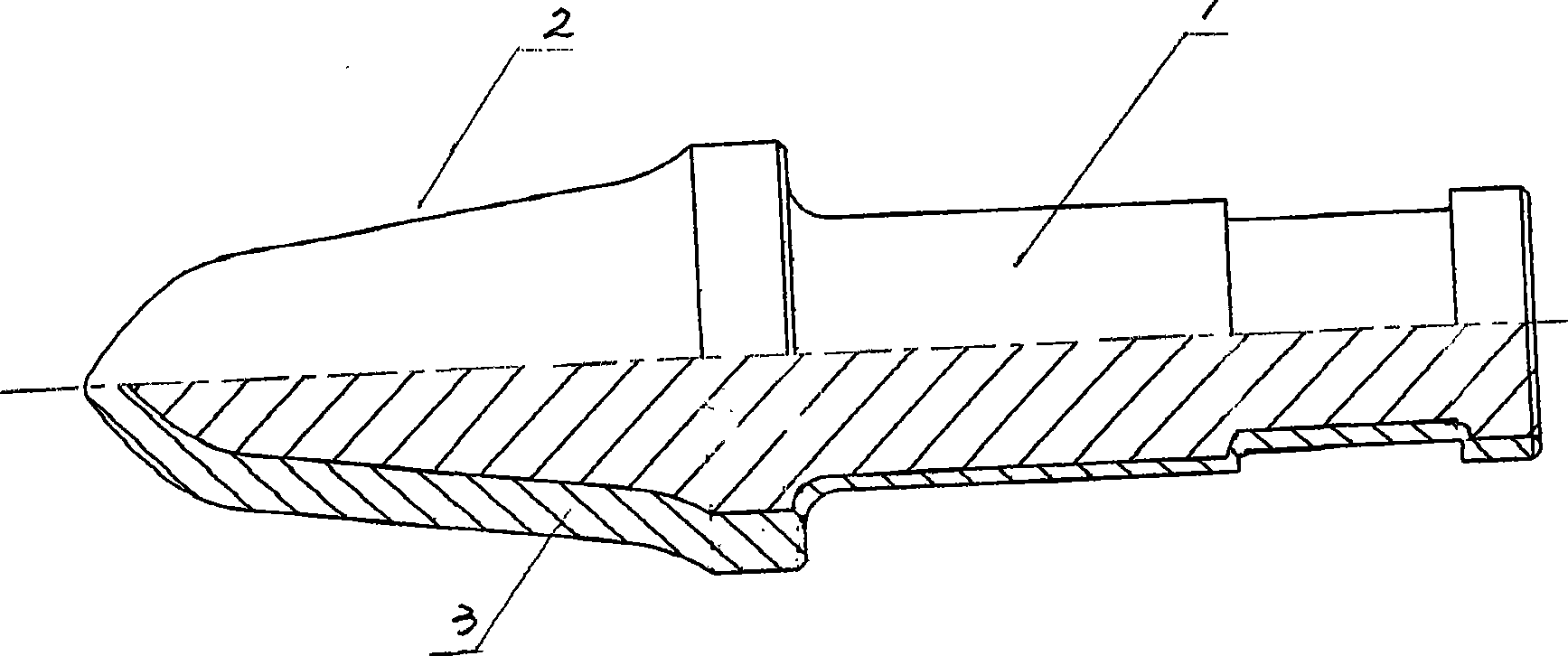

[0025] Such as figure 1 As shown, the one-piece conical pick of the present invention includes a conical pick body, the conical pick body contains a tooth body 1 and a tooth tip 2, the tooth body 1 is cylindrical, and the tooth tip 2 is a cone The tooth body 1 and the tooth tip 2 are made of the same material, and one end of the tooth body 1 and the large end of the tooth tip 2 are integrally formed by casting. A wear-resistant layer 3 is formed on the surface of the tapered pick body.

[0026] One-piece conical pick production method of the present invention comprises the following steps successively:

[0027] First select carbon tool steel rod, the carbon tool steel rod is T9A high-quality carbon tool steel;

[0028] Then, precision forging

[0029] Forge carbon tool steel rods into conical pick blanks of required specifications. Among them, the initial forging temperature is 1000°C, and the final forging temperature is 700°C.

[0030] After that, spheroidizing annealin...

Embodiment 2

[0046] Such as figure 1 As shown, the one-piece conical pick of the present invention includes a conical pick body, the conical pick body contains a tooth body 1 and a tooth tip 2, the tooth 1 body is cylindrical, and the tooth tip 2 is a cone The tooth body 1 and the tooth tip 2 are made of the same material, and one end of the tooth body 1 and the large end of the tooth tip 2 are integrally formed by casting. A wear-resistant layer 3 is formed on the surface of the tapered pick body.

[0047] One-piece conical pick production method of the present invention comprises the following steps successively:

[0048] First select carbon tool steel rod, the carbon tool steel rod is T10A high-quality carbon tool steel;

[0049] Then, precision forging

[0050] Forge carbon tool steel rods into conical pick blanks of required specifications. Among them, the initial forging temperature is 1100°C, and the final forging temperature is 760°C.

[0051] After that, spheroidizing anneali...

Embodiment 3

[0067] Such as figure 1 As shown, the one-piece conical pick of the present invention includes a conical pick body, the conical pick body contains a tooth body 1 and a tooth tip 2, the tooth body 1 is cylindrical, and the tooth tip 2 is a cone The tooth body 1 and the tooth tip 2 are made of the same material, and one end of the tooth body 1 and the large end of the tooth tip 2 are integrally formed by casting. A wear-resistant layer 3 is formed on the surface of the tapered pick body.

[0068] One-piece conical pick production method of the present invention comprises the following steps successively:

[0069] First select carbon tool steel rod, the carbon tool steel rod is T11A high-quality carbon tool steel;

[0070] Then, precision forging

[0071] Forge carbon tool steel rods into conical pick blanks of required specifications. Among them, the initial forging temperature is 1160°C, and the final forging temperature is 820°C.

[0072] After that, spheroidizing anneali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com