Method for preparing diamond film on stainless steel surface with Cr/CrAlN as transition layer

A diamond thin film and stainless steel technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve the problems of difficult formation of diamond thin film, poor thermal expansion coefficient, low hardness of the film, etc., and achieve excellent film-base bonding force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

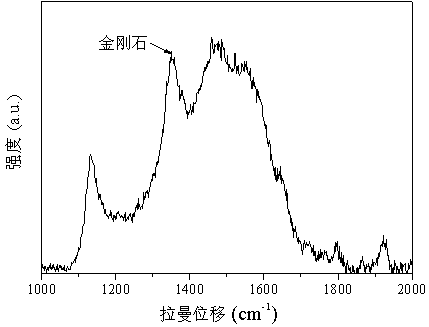

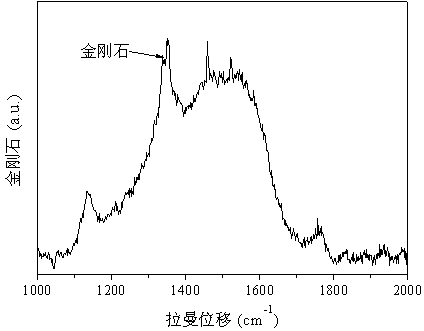

[0031] Grind 3Cr13 stainless steel with 600#, 800#, 1200#, 1500#, 2000# sandpaper in sequence, then ultrasonically shake the polished samples with acetone and absolute ethanol for 20 minutes, dry them quickly with a hair dryer, and put them into PVD Cr / CrAlN transition layer deposition is carried out in the equipment. The purity of the Cr target and the Al target used in the deposition process are both 99.999%, and the target base distance is 70 mm. The process parameters for depositing the Cr layer are: vacuum degree 1×10 –3 Pa, the Ar gas flow is 20 sccm, the working pressure is 0.8 Pa, the Cr target power is 100 W, the substrate temperature is 300 °C, and the deposition time is 20 min. The process parameters for preparing the CrAlN layer are: Ar gas flow rate is 20 sccm, N 2 The gas flow rate is 5 sccm, the working pressure is 1 Pa, the Al target power is 120 W, the Cr target power is 100 W, the substrate temperature is 300 °C, and the deposition time is 60 min; In an a...

Embodiment 2

[0034] Grind 3Cr13 stainless steel with 600#, 800#, 1200#, 1500#, 2000# sandpaper in sequence, then ultrasonically shake the polished samples with acetone and absolute ethanol for 20 minutes, dry them quickly with a hair dryer, and put them into PVD equipment The deposition of Cr / CrAlN transition layer is carried out in the middle. During the deposition process, the purity of both Cr and Al targets was 99.999%, and the target-base distance was 70 mm. The process parameters for depositing the Cr layer are: vacuum degree 0.8×10 –3 Pa, the Ar gas flow rate is 20 sccm, the working pressure is 0.8 Pa, the Cr target power is 100 W, and the deposition time is 40 min. The process parameters for preparing the CrAlN layer are: Ar gas flow rate is 20 sccm, N 2 The gas flow rate is 5 sccm, the working pressure is 1.0 Pa, the Al target power is 180 W, the Cr target power is 100 W, the substrate temperature is 300 °C, and the deposition time is 120 min; In an acetone solution containing ...

Embodiment 3

[0037] Grind the 3Cr13 stainless steel with 600#, 800#, 1200#, 1500#, 2000# sandpaper in sequence, ultrasonically shake the polished samples with acetone and absolute ethanol for 20 minutes, dry them quickly with a hair dryer, and put them into the PVD equipment A Cr / CrAlN transition layer deposition is performed. The purity of the Cr and Al targets used in the deposition process is both 99.999%, and the target base distance is 70 mm. The process parameters for depositing the Cr layer are: the degree of vacuum is 0.7×10 –3 Pa, the Ar gas flow rate is 20 sccm, the working pressure is 0.8 Pa, the Cr target power is 100 W, and the deposition time is 10 min. The process parameters for preparing the CrAlN layer are: Ar gas flow rate is 20 sccm, N 2 The gas flow is 5 sccm, the working pressure is 1 Pa, the Al target power is 30 W, the Cr target power is 100 W, the substrate temperature is 300 °C, and the deposition time is 20 min. Then the sample of the Cr / CrAlN film transition ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com