Patents

Literature

36results about How to "Poor bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

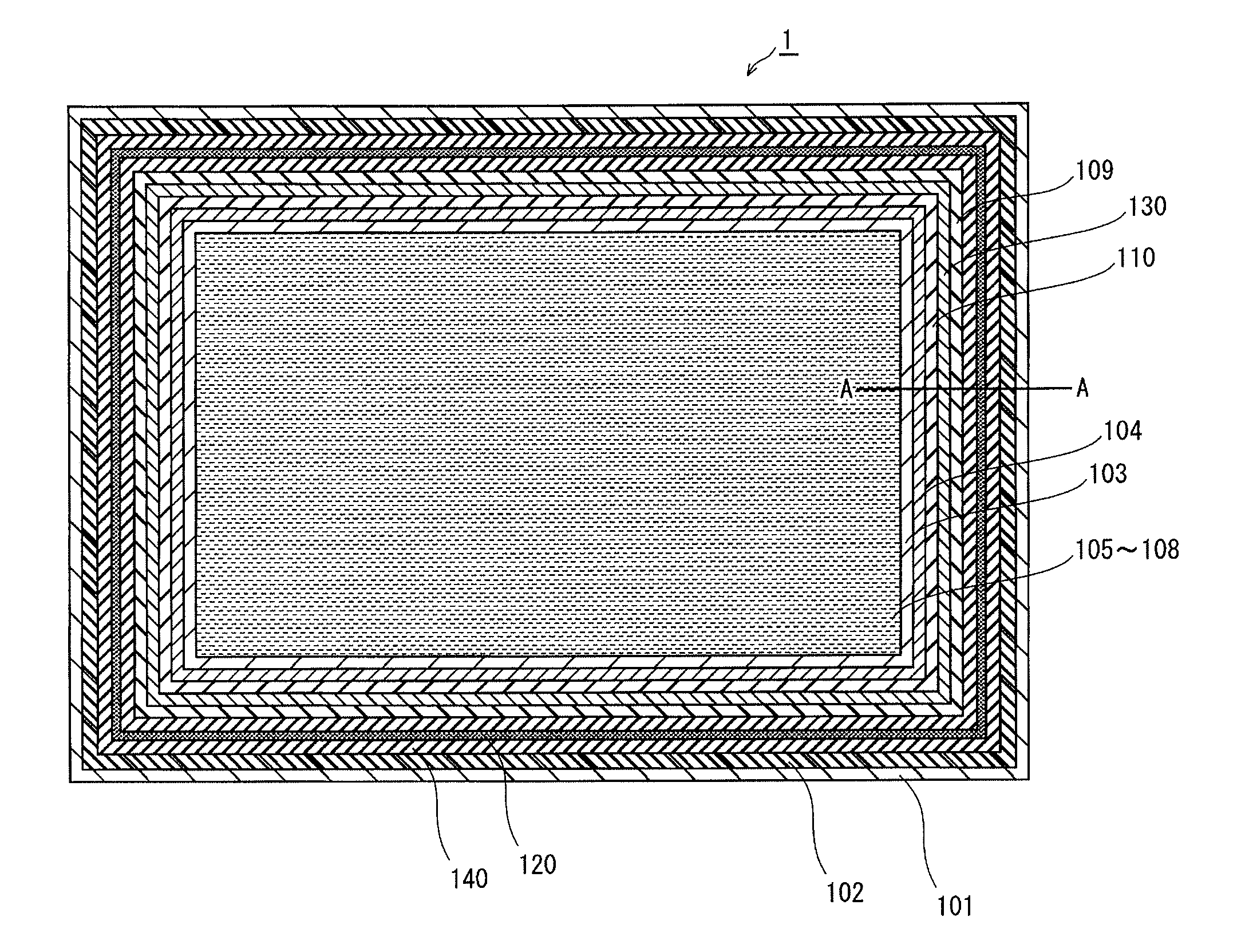

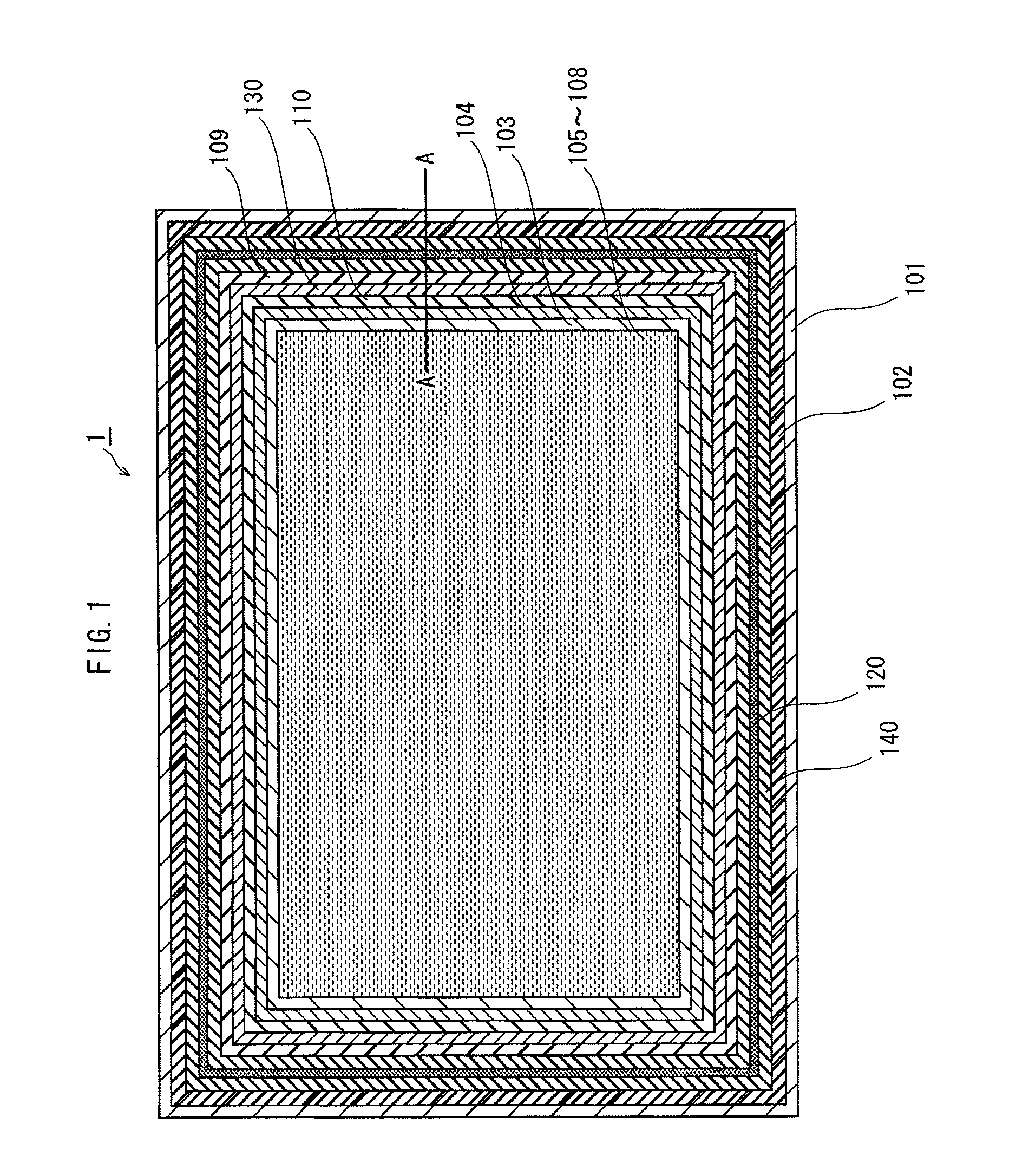

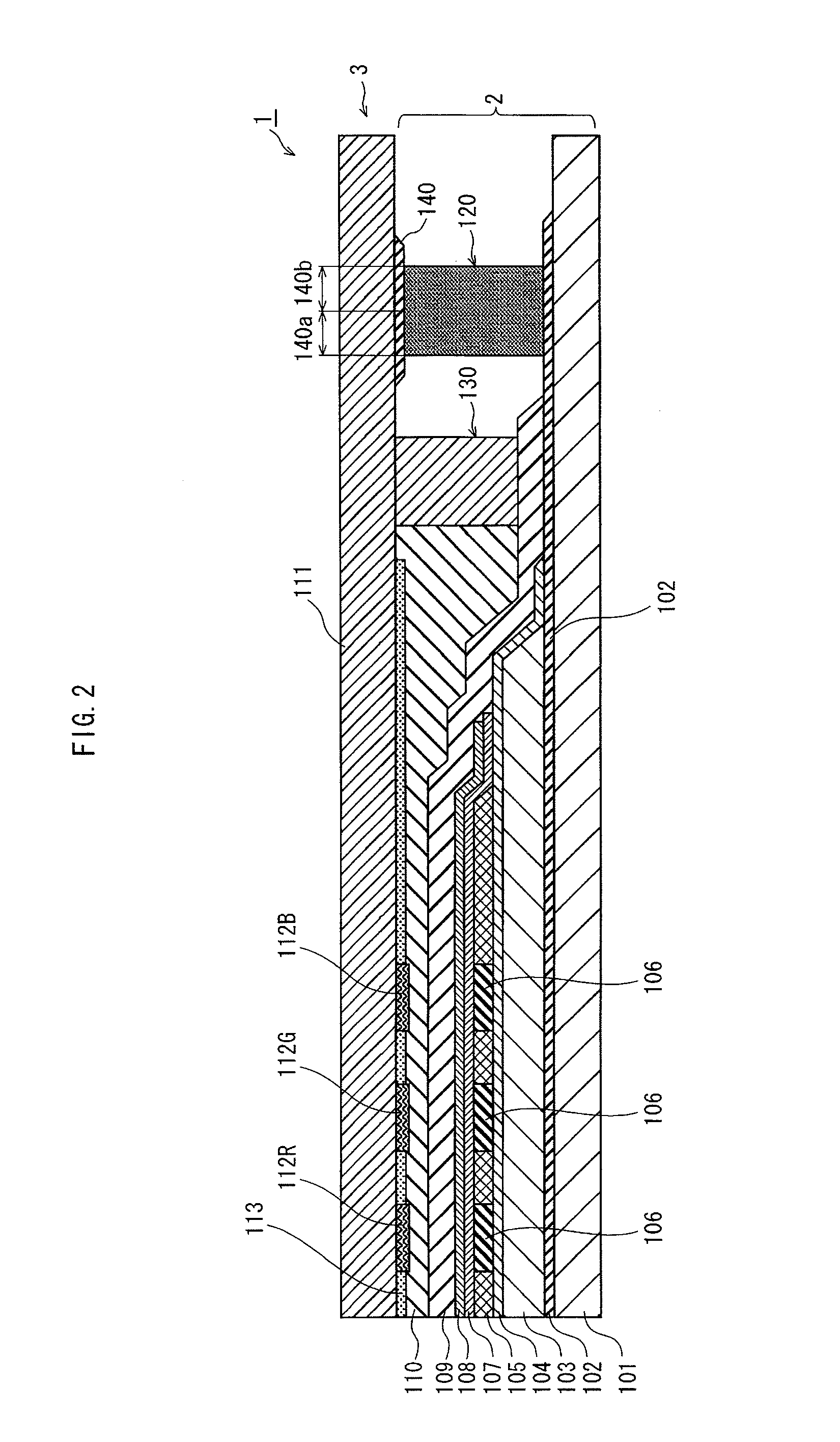

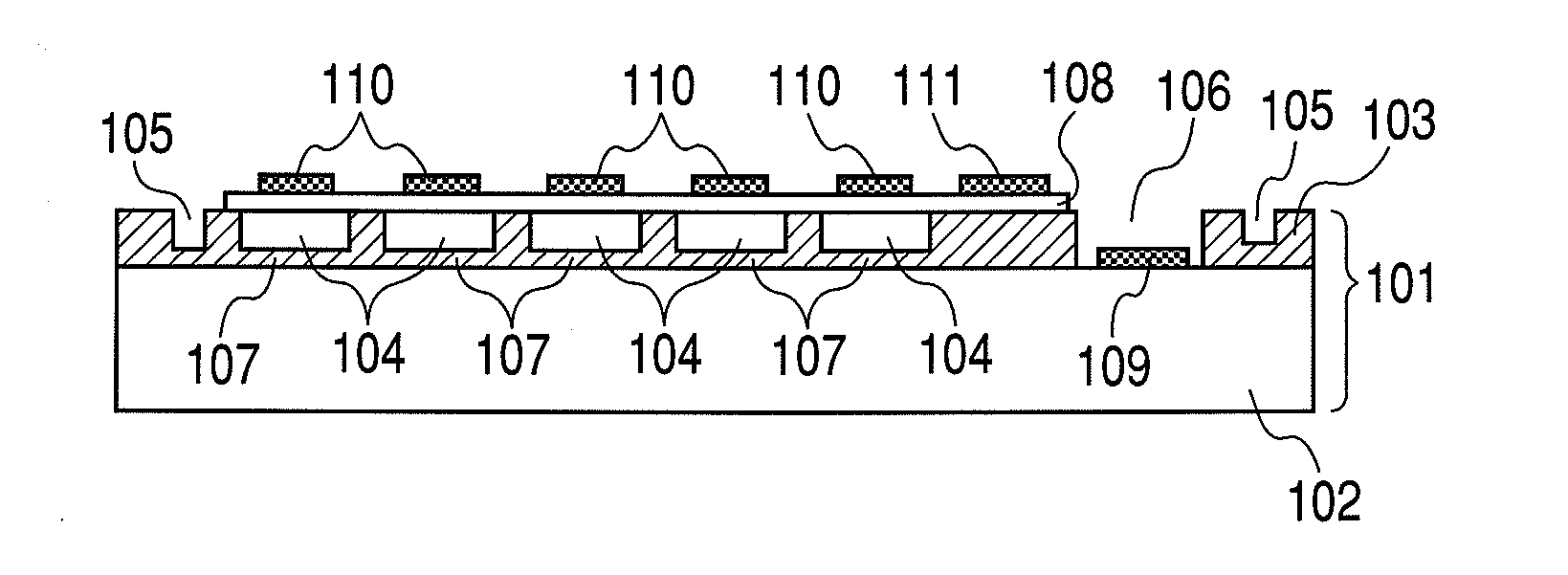

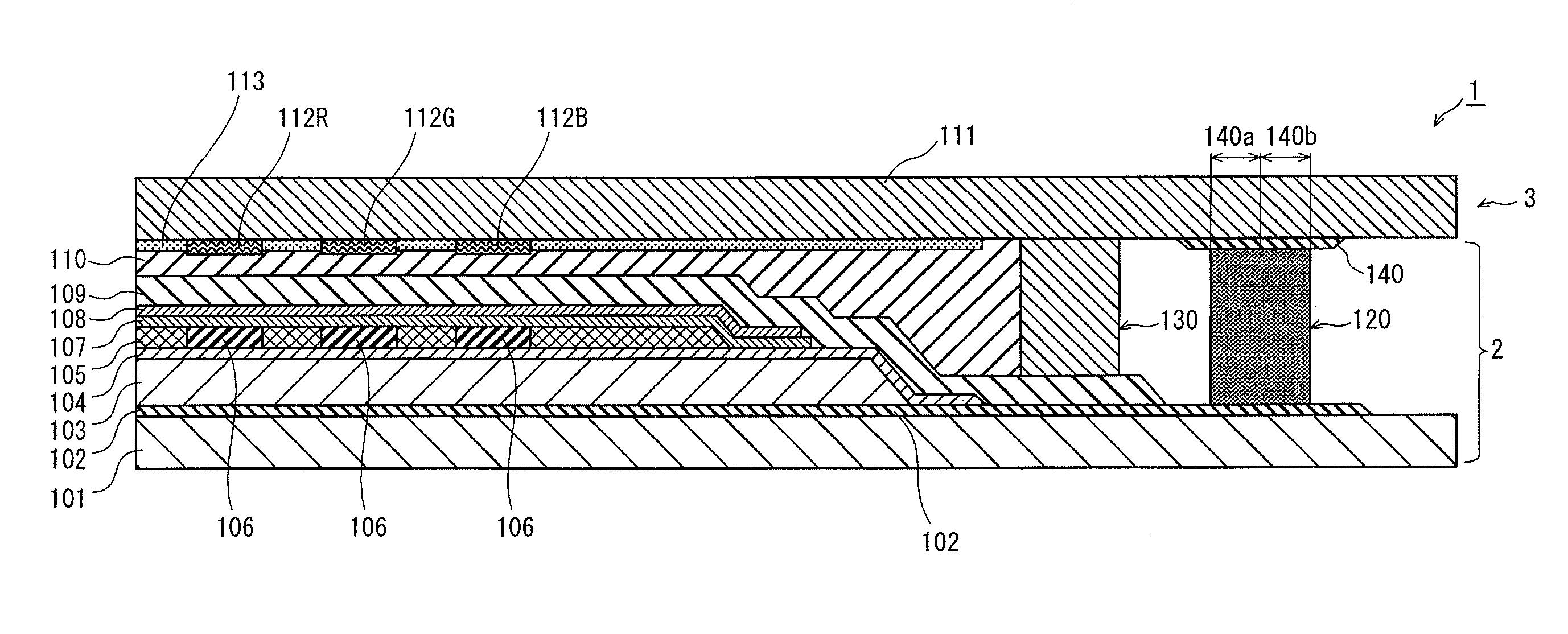

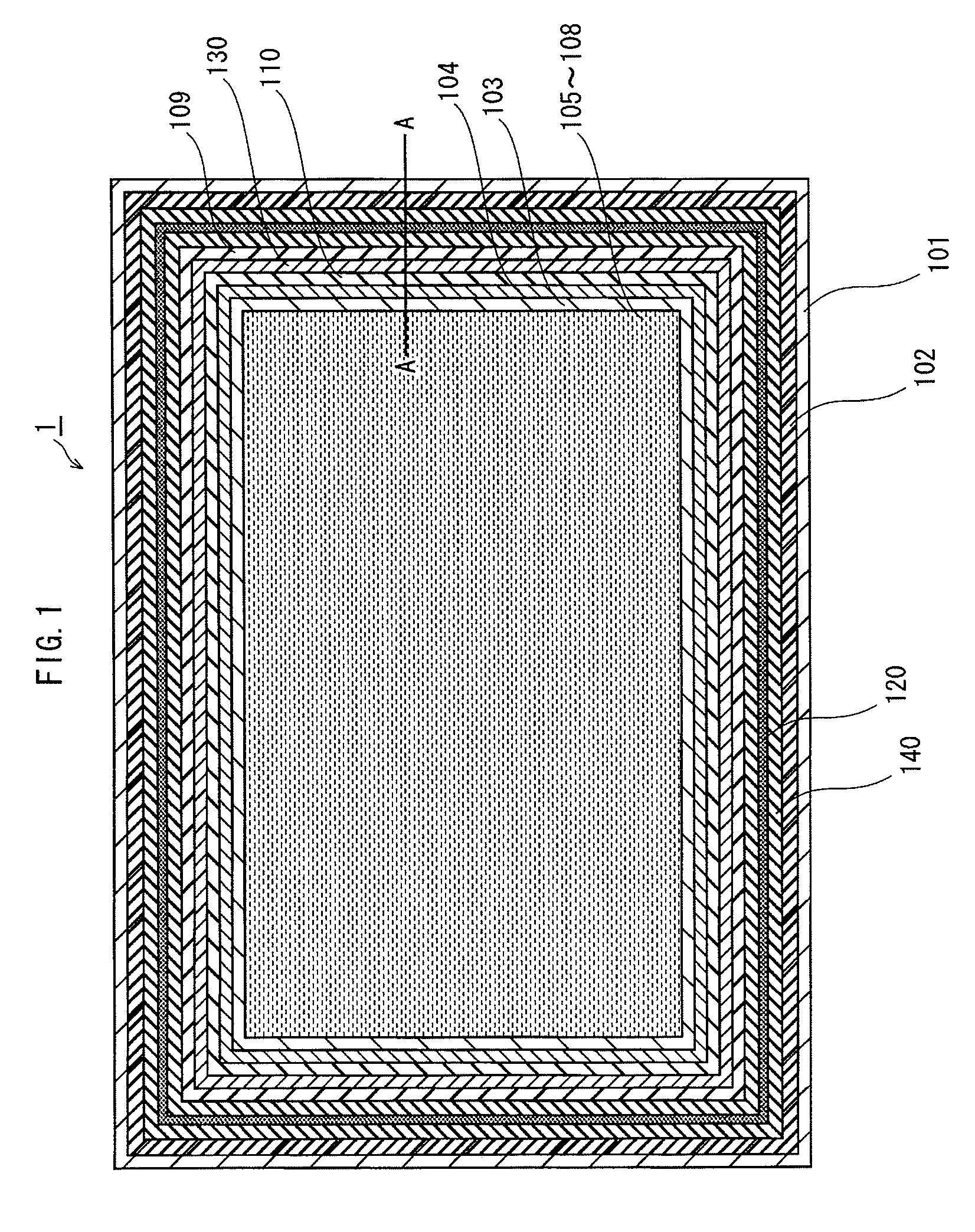

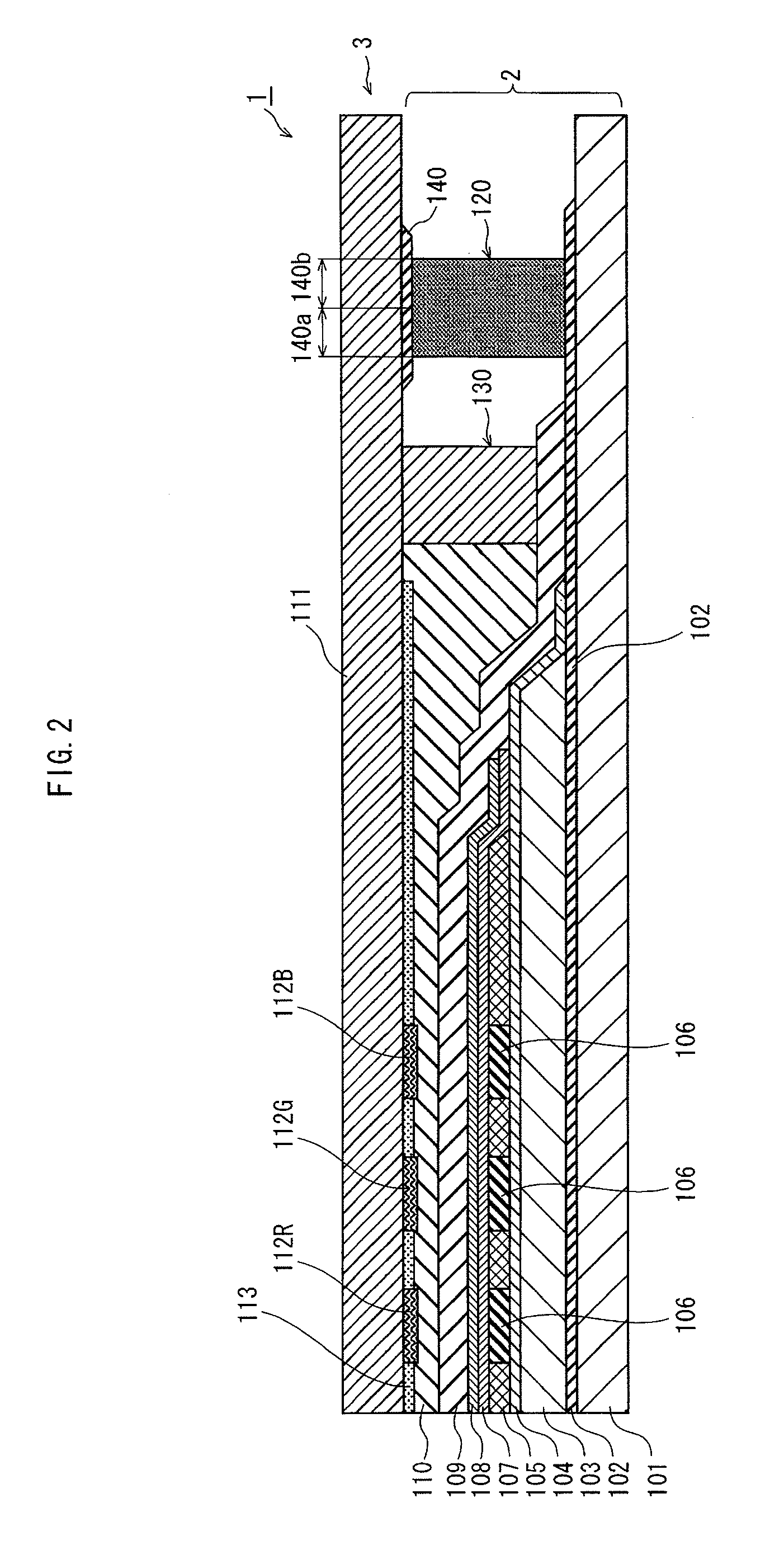

Display panel and production method thereof

ActiveUS20120287026A1Improve deteriorationReduced Surface Flatness RequirementsLamination ancillary operationsStatic indicating devicesPhoto irradiationHermetic seal

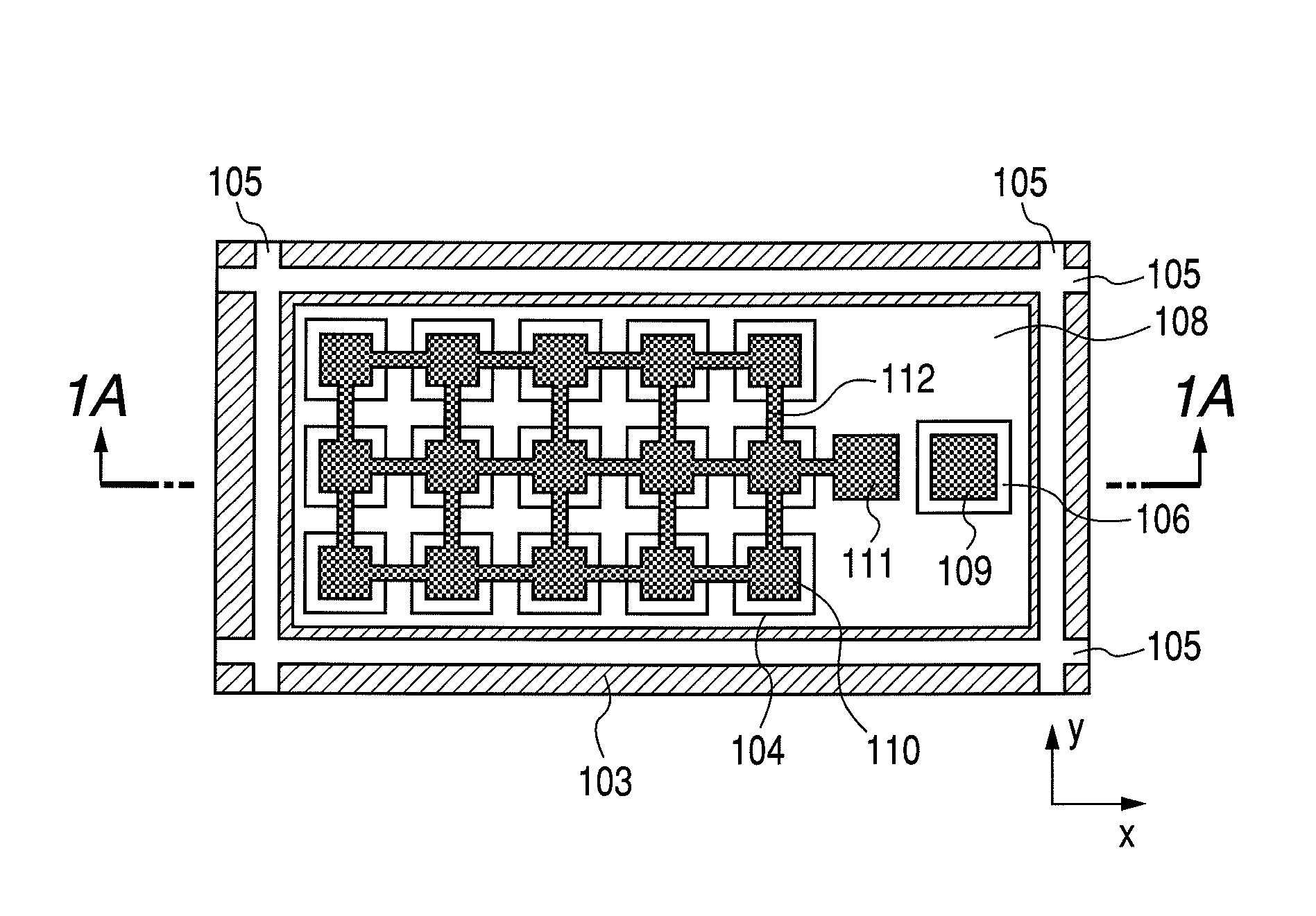

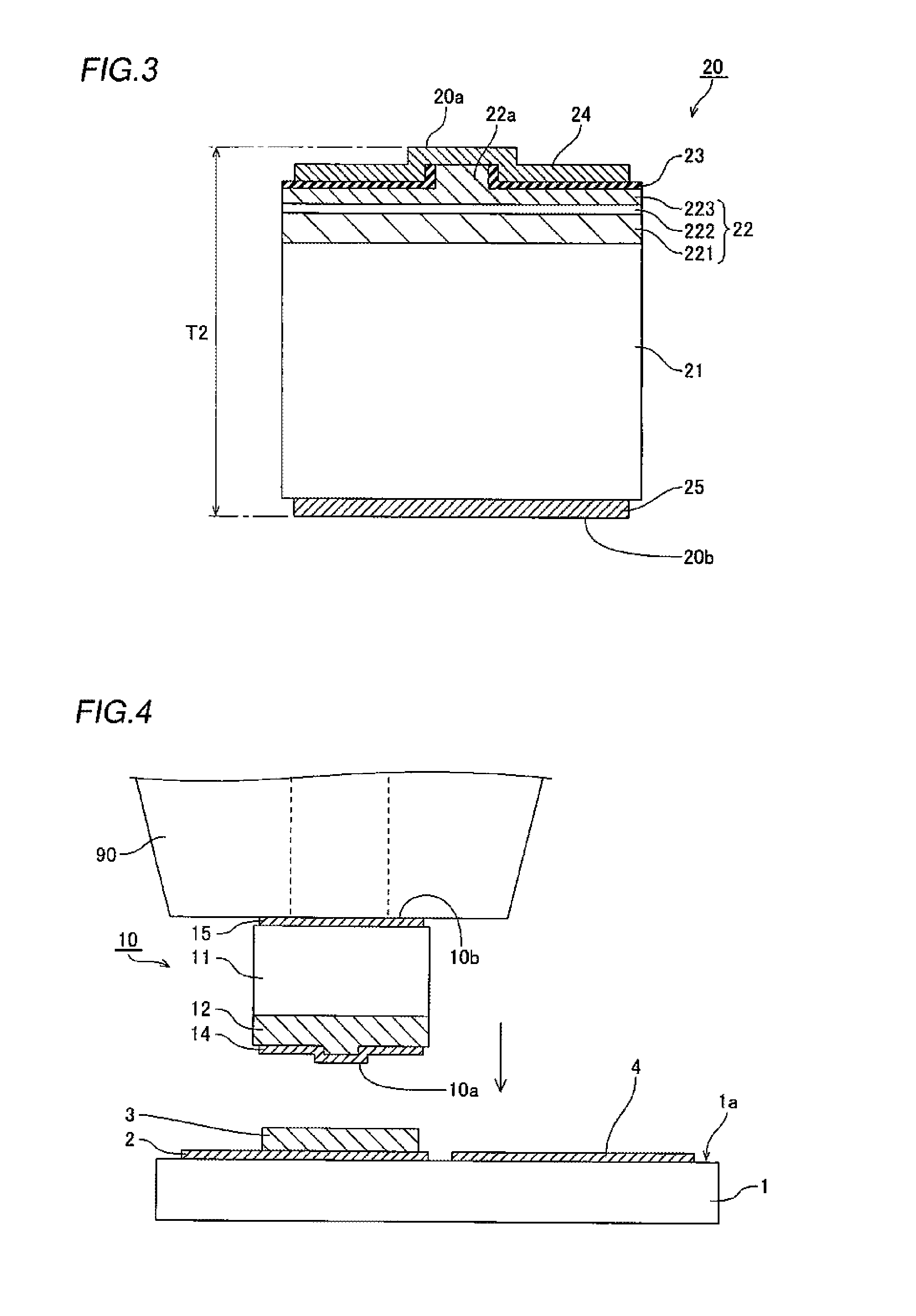

A display panel includes: a first substrate; light-emitting elements on a region of the first substrate; a second substrate facing the first substrate with the light-emitting elements therebetween; a glass frit between the first substrate and the second substrate so as to surround the region of the first substrate in which the light-emitting elements are disposed, the glass frit providing a hermetic seal between the first substrate and the second substrate; and a light-shielding part formed on one of the first substrate and the second substrate so as to extend along the glass frit, the light-shielding part shielding light. The light-shielding part has a lower light-shielding property in a region corresponding to the outer region of the glass frit than in a region corresponding to the inner region of the glass frit. The glass frit has been irradiated with light through the light-shielding part.

Owner:JOLED INC

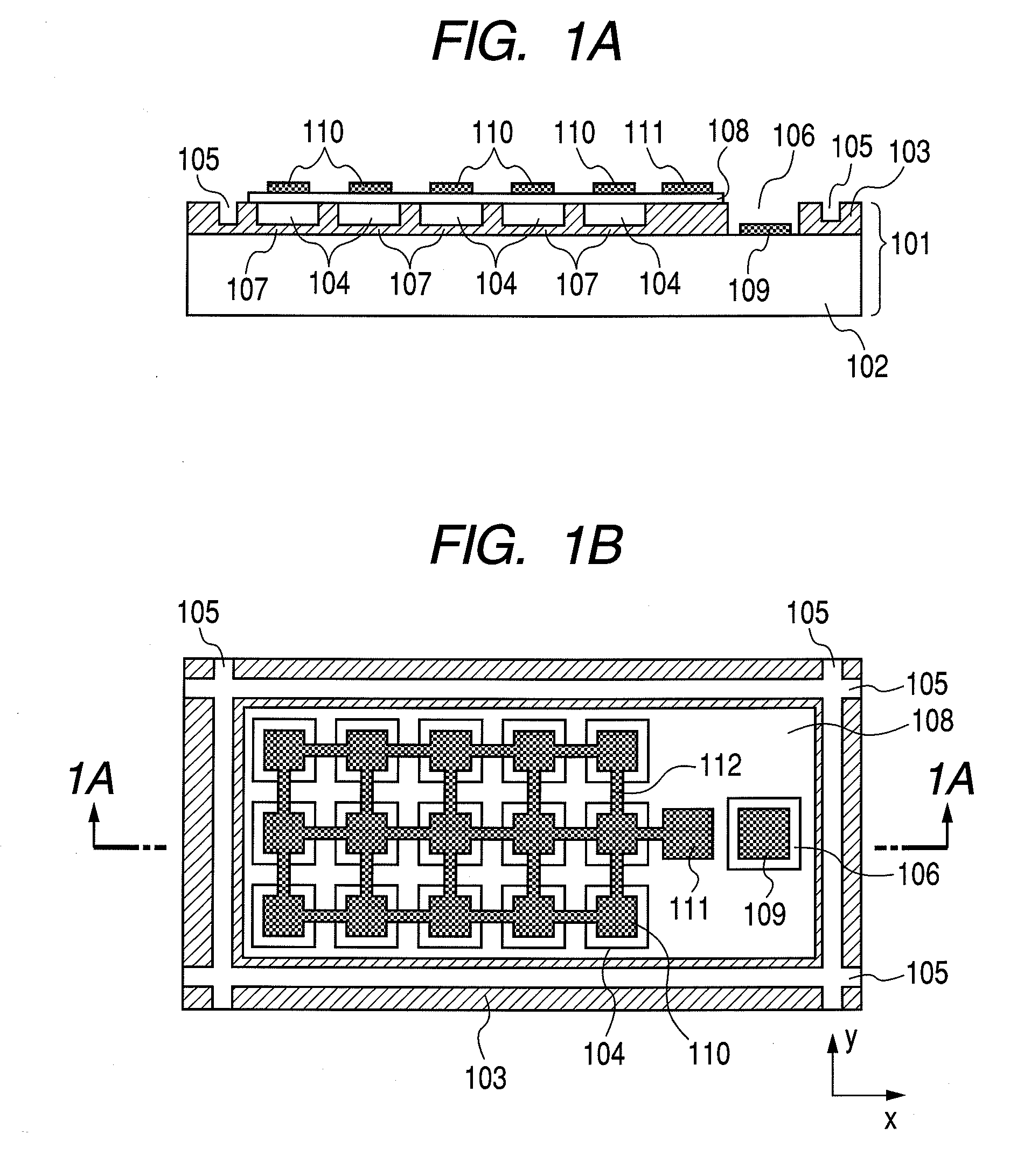

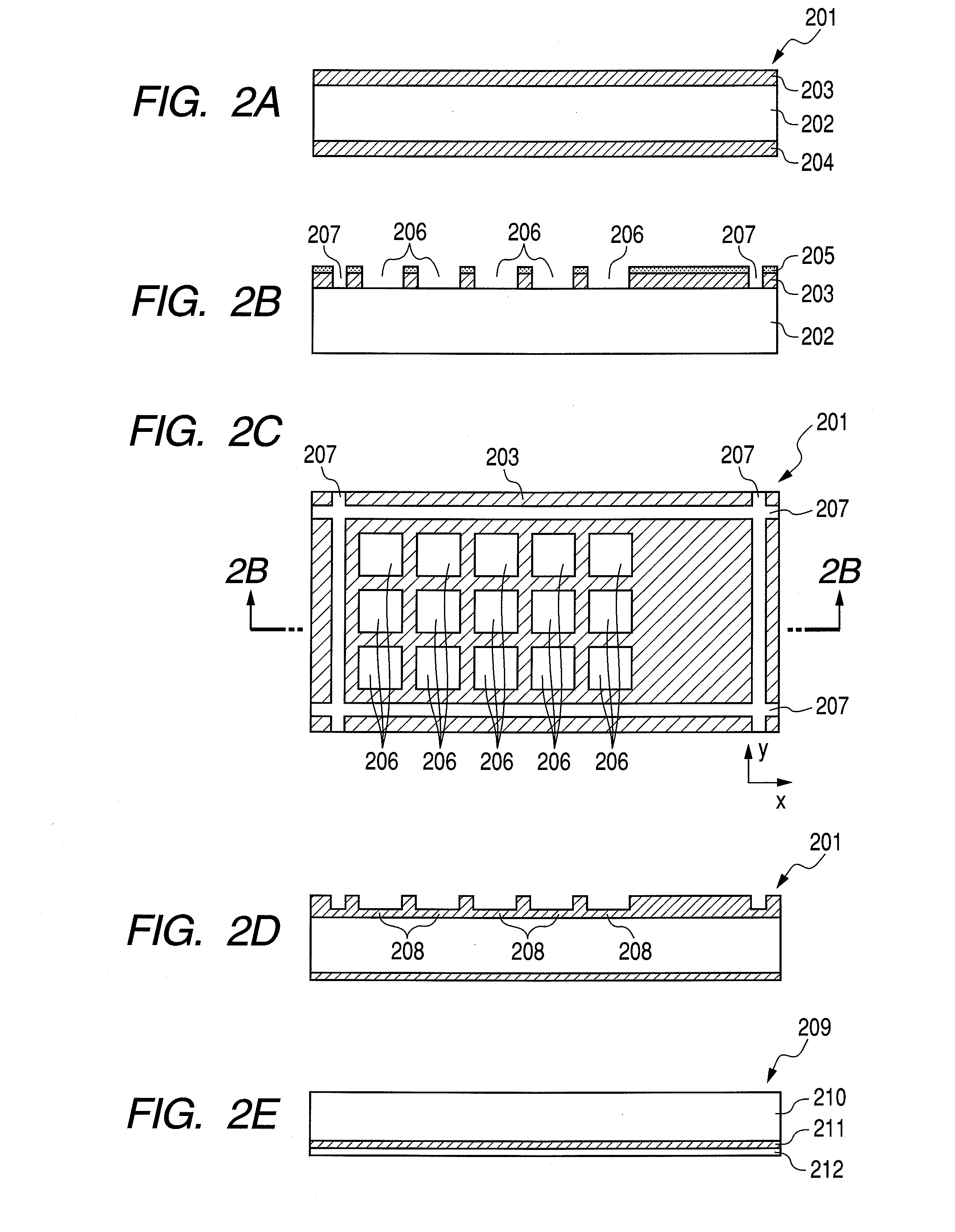

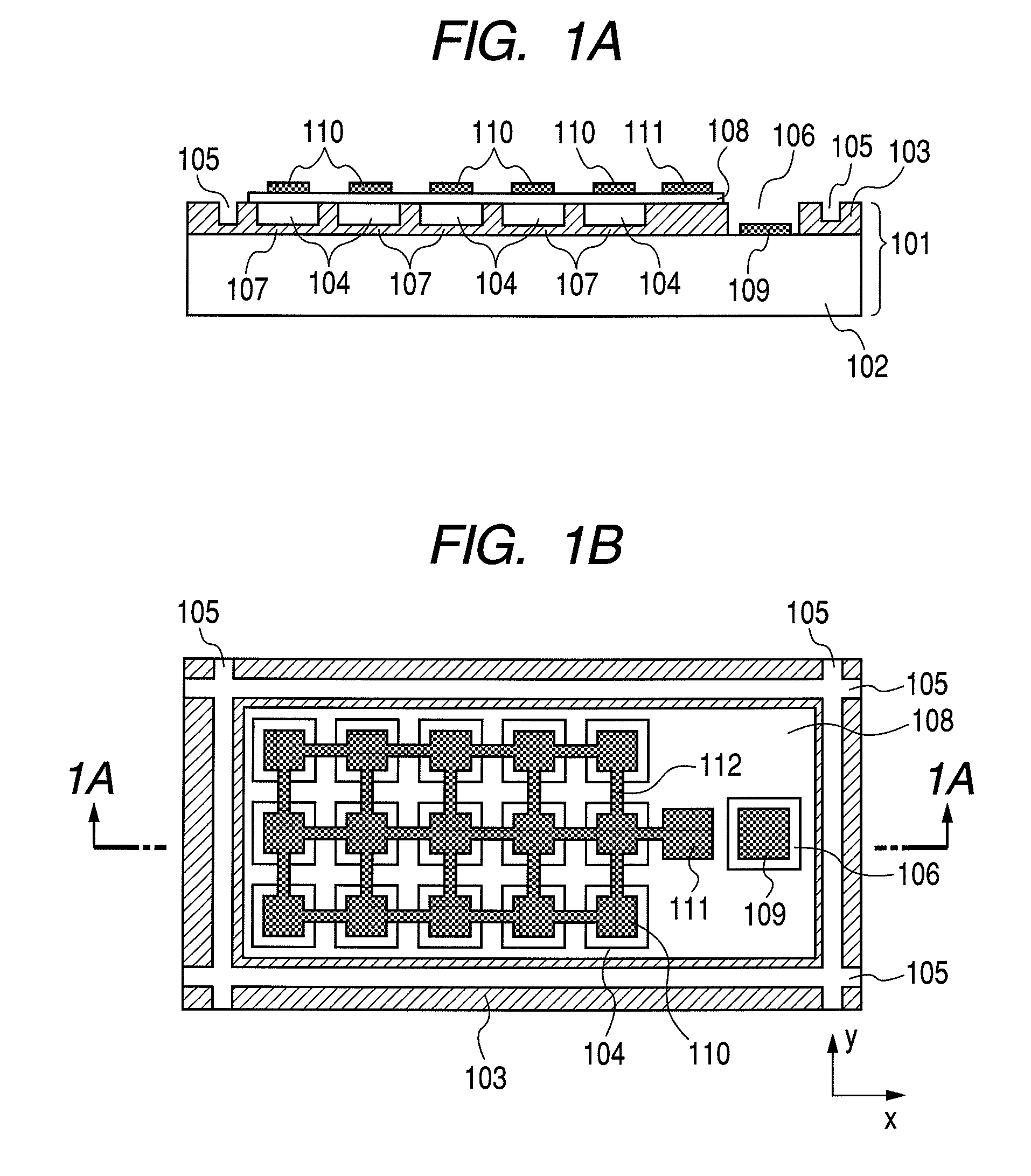

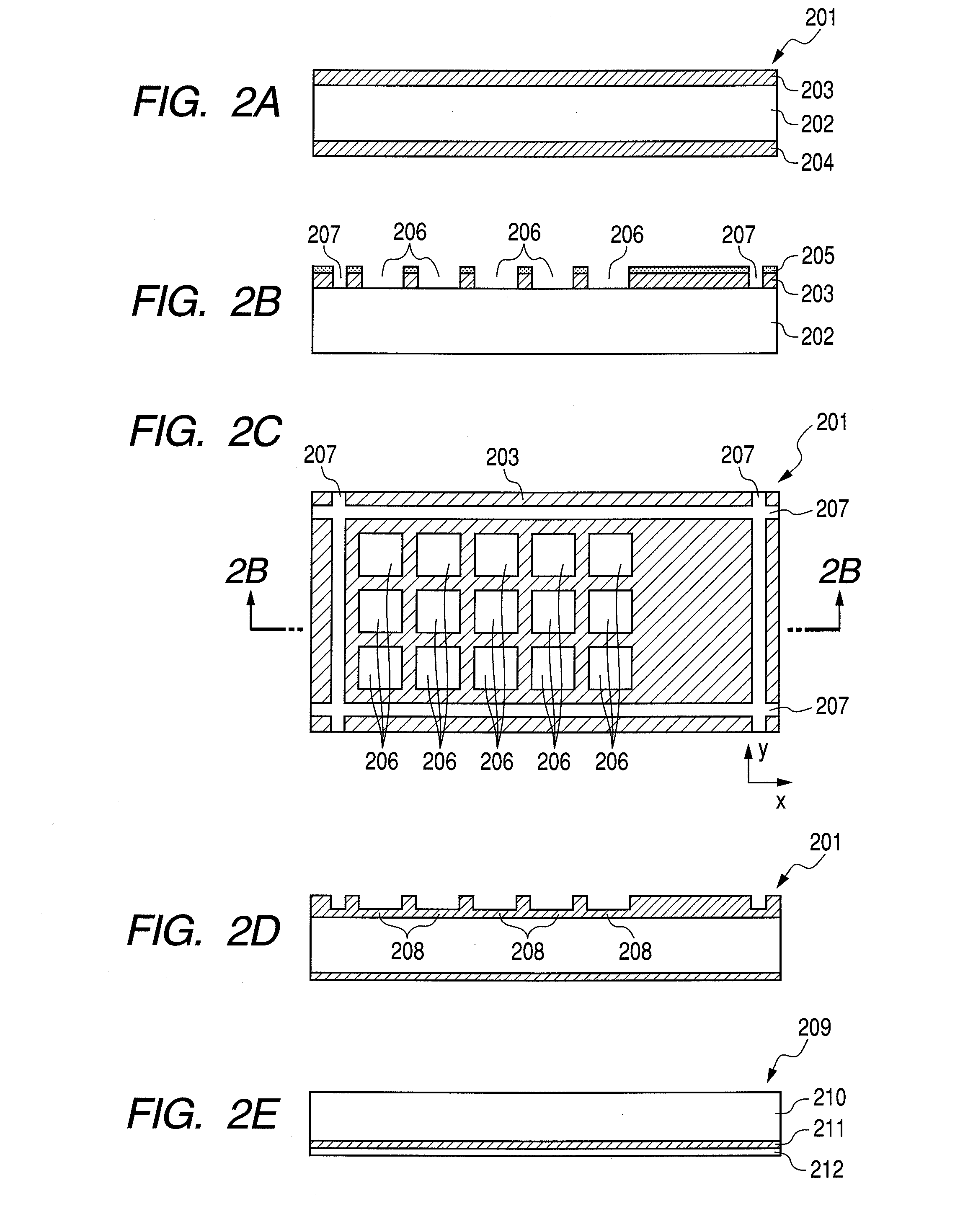

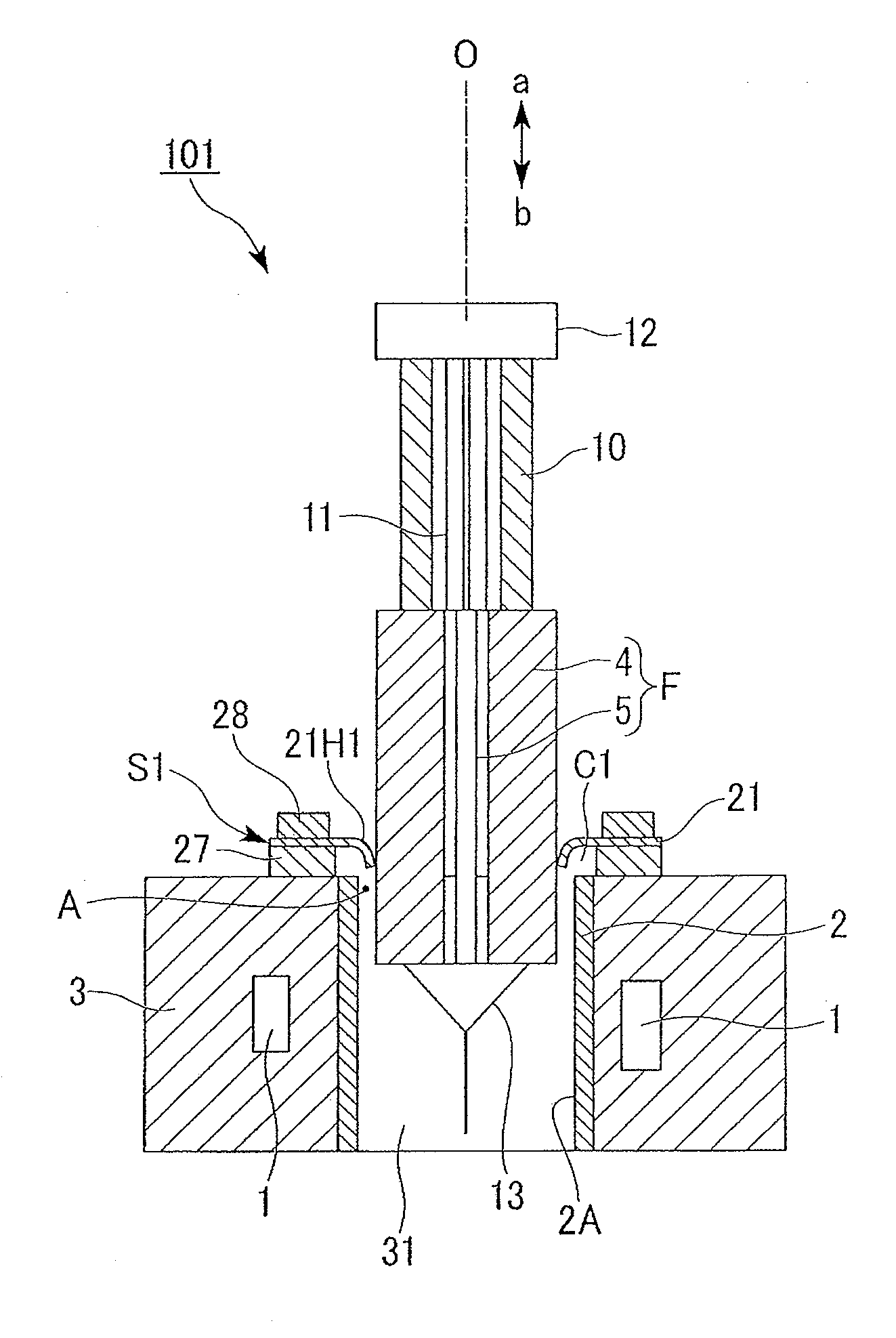

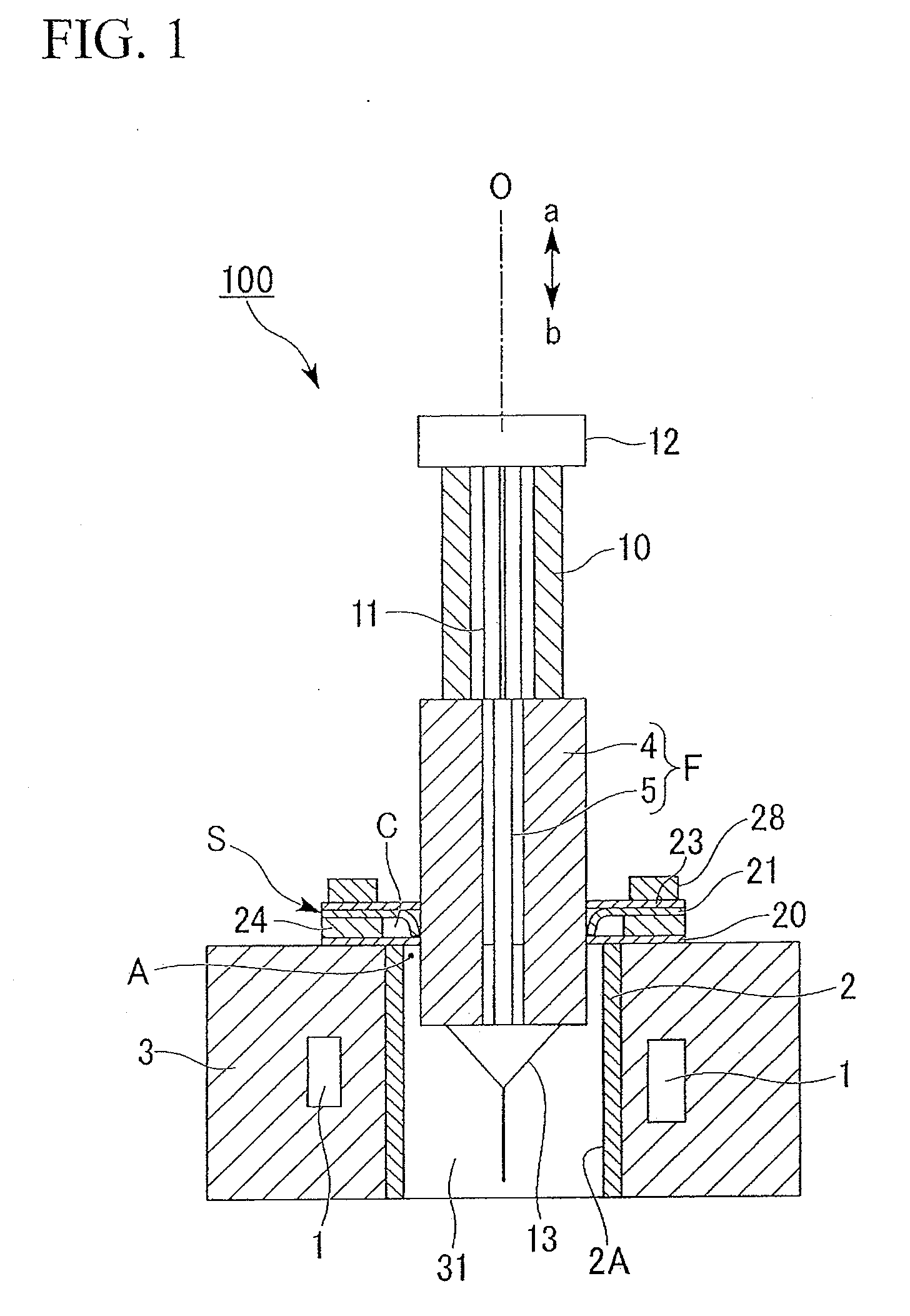

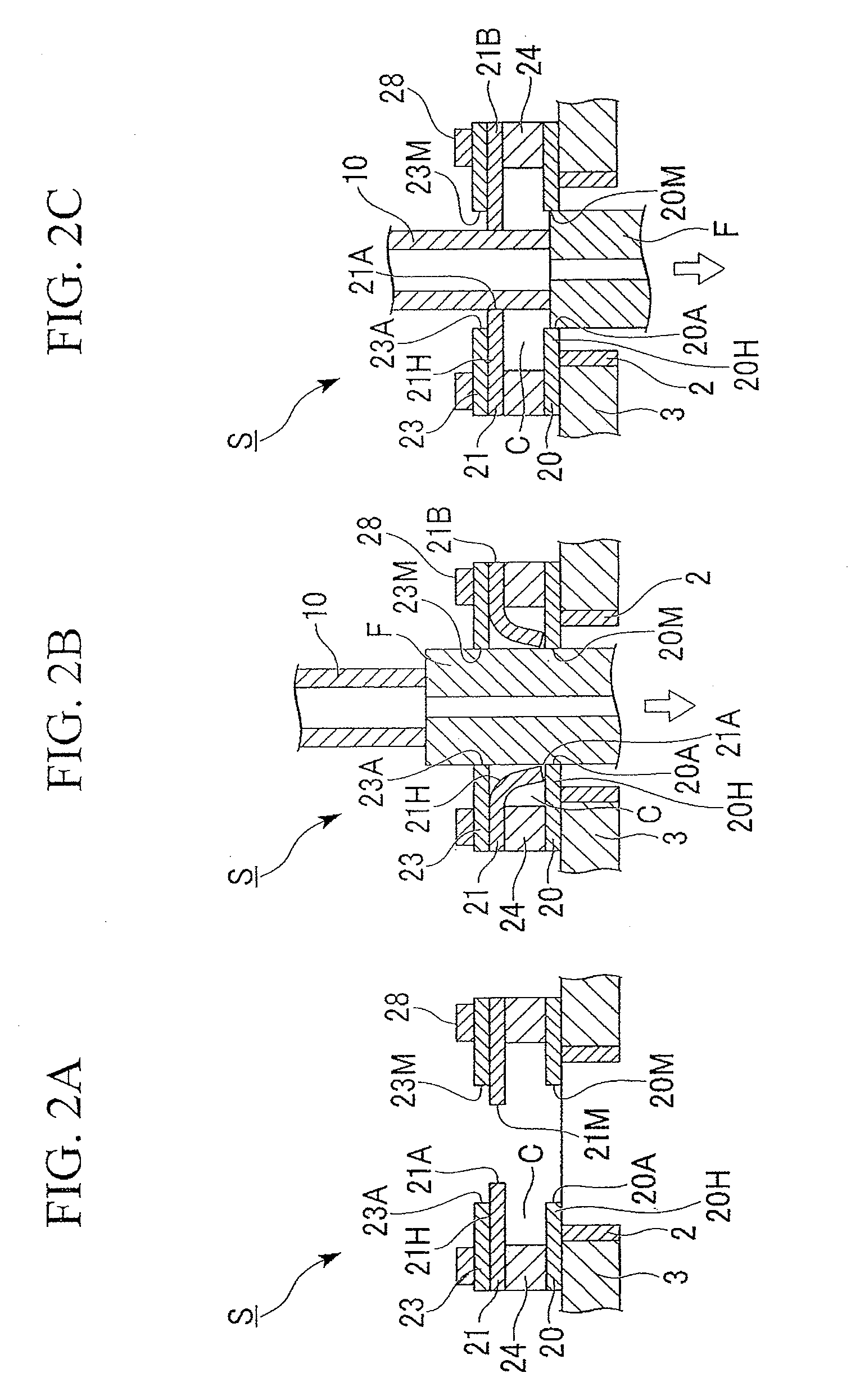

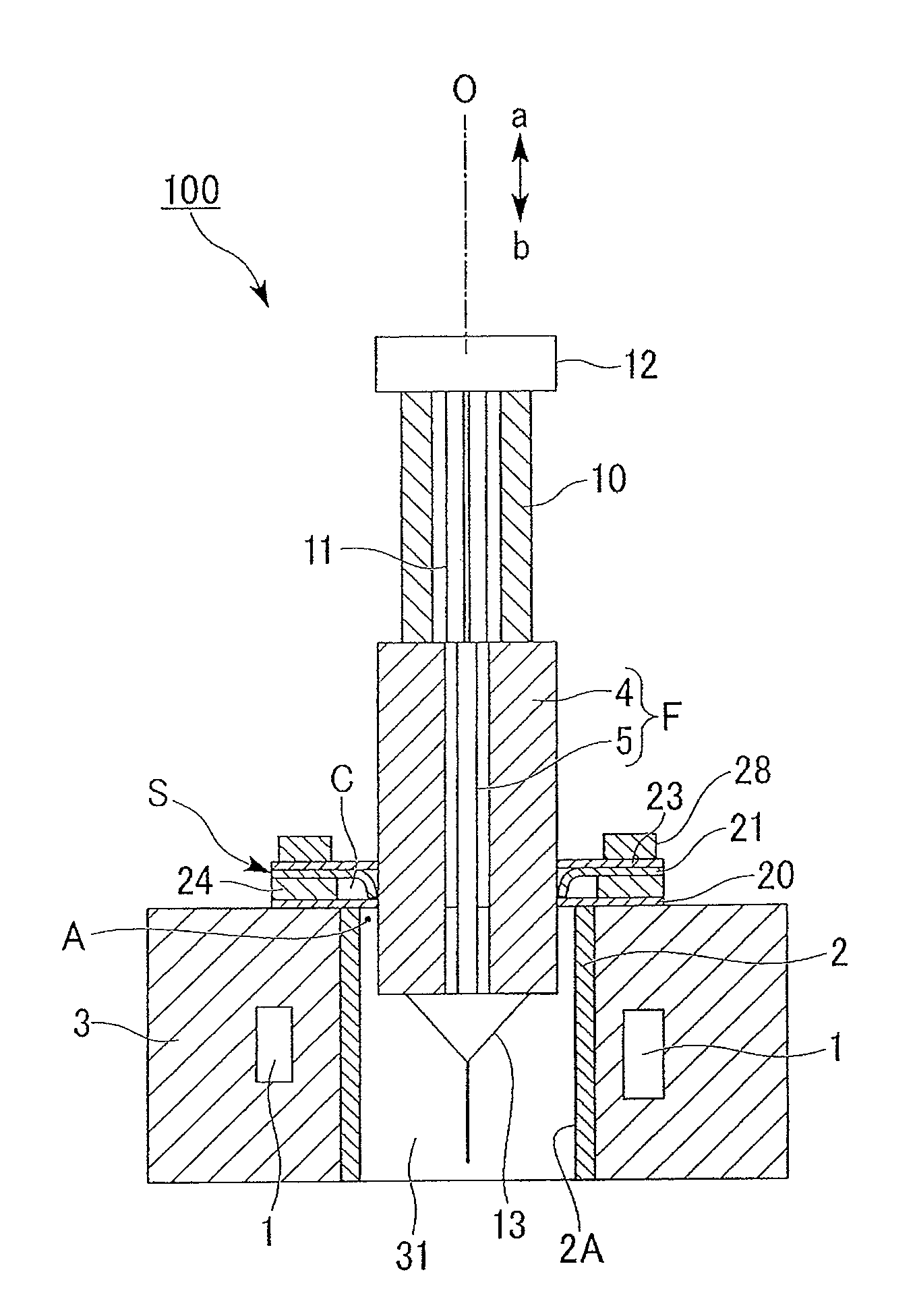

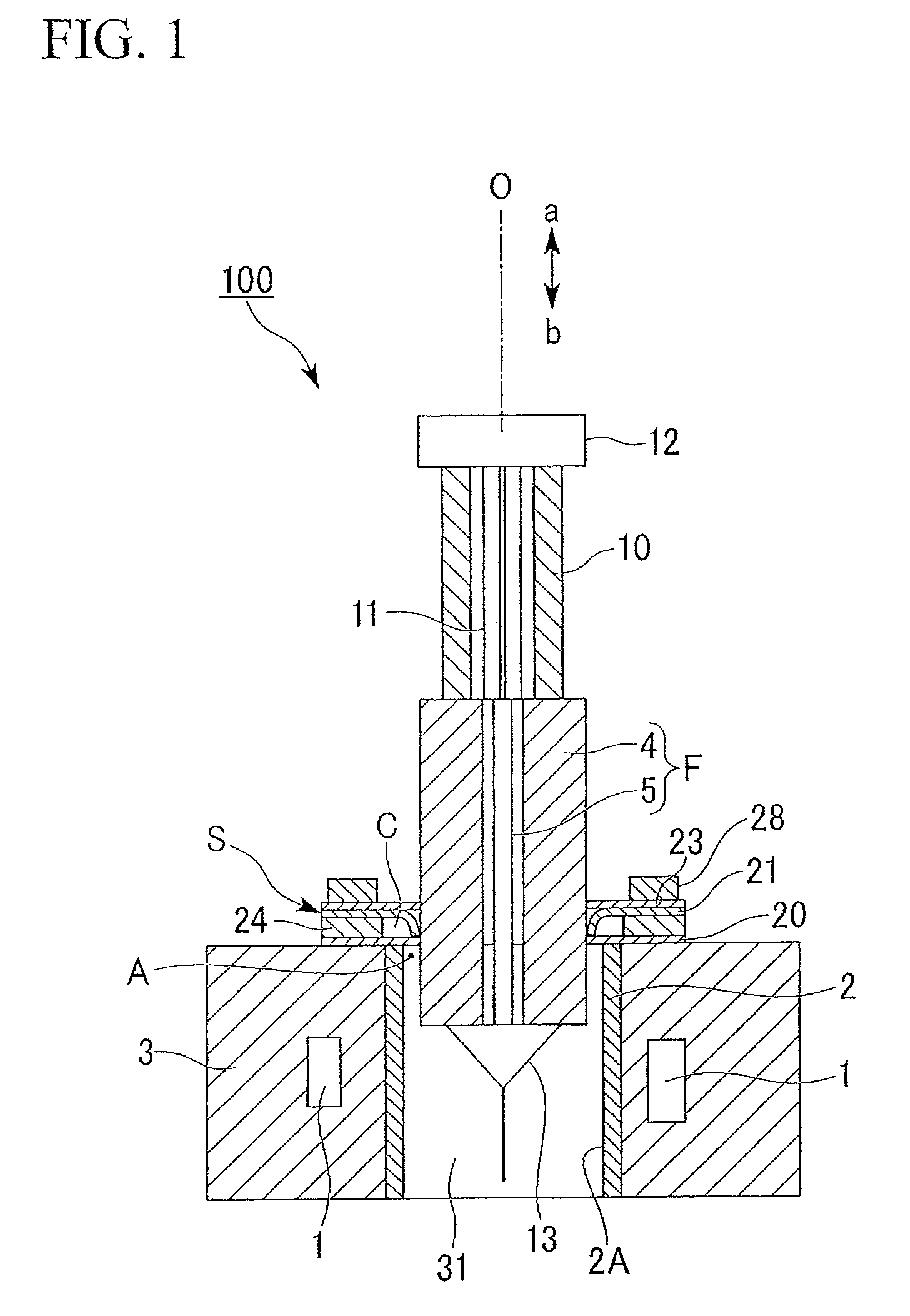

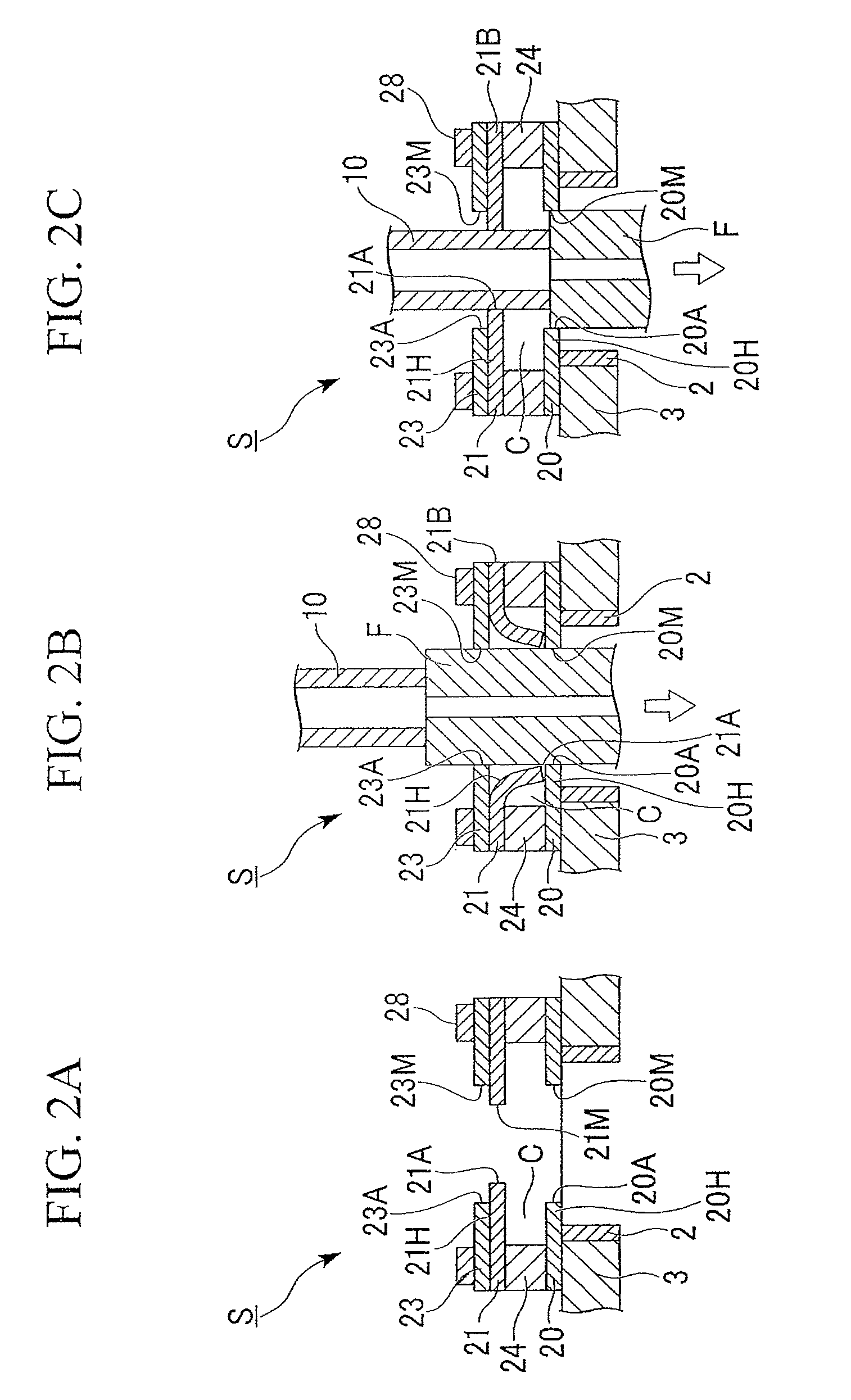

Process for producing capacitive electromechanical conversion device, and capacitive electromechanical conversion device

InactiveUS20110084570A1Poor bondingBeacon systems using ultrasonic/sonic/infrasonic wavesWave amplification devicesBond interfaceEngineering

A process for producing a capacitive electromechanical conversion device by bonding together a substrate and a membrane member to form a cavity sealed between the substrate and the membrane member, the process for producing a capacitive electromechanical conversion device comprises the steps of: providing a gas release path penetrating from a bonded interface between the substrate and the membrane member to the outside, and forming the cavity by bonding the membrane member with the substrate with the gas release path provided; the gas release path being provided at a location where the path does not communicate with the cavity.

Owner:CANON KK

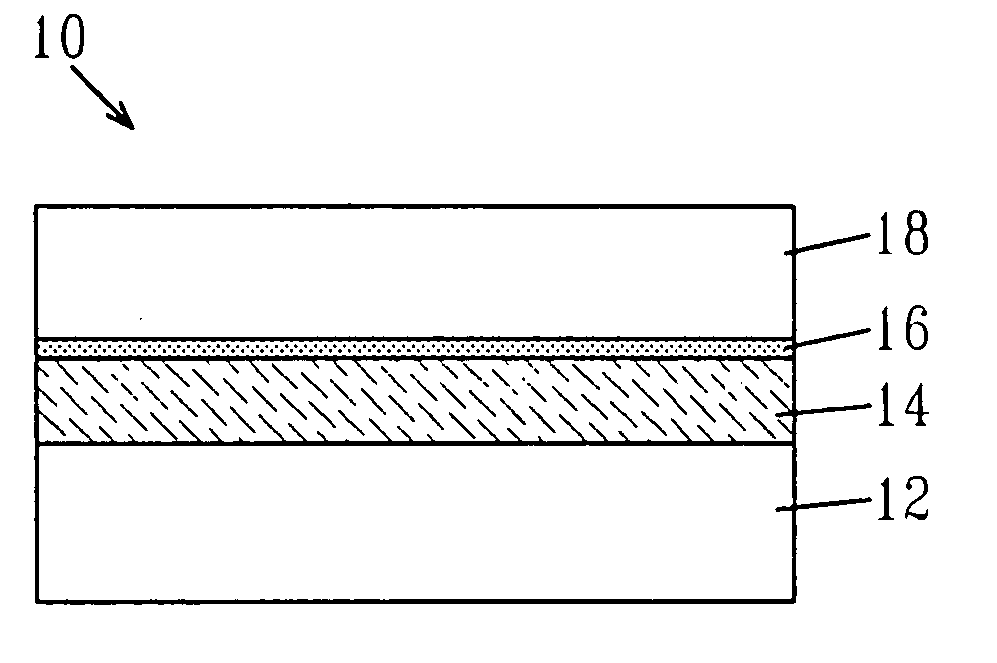

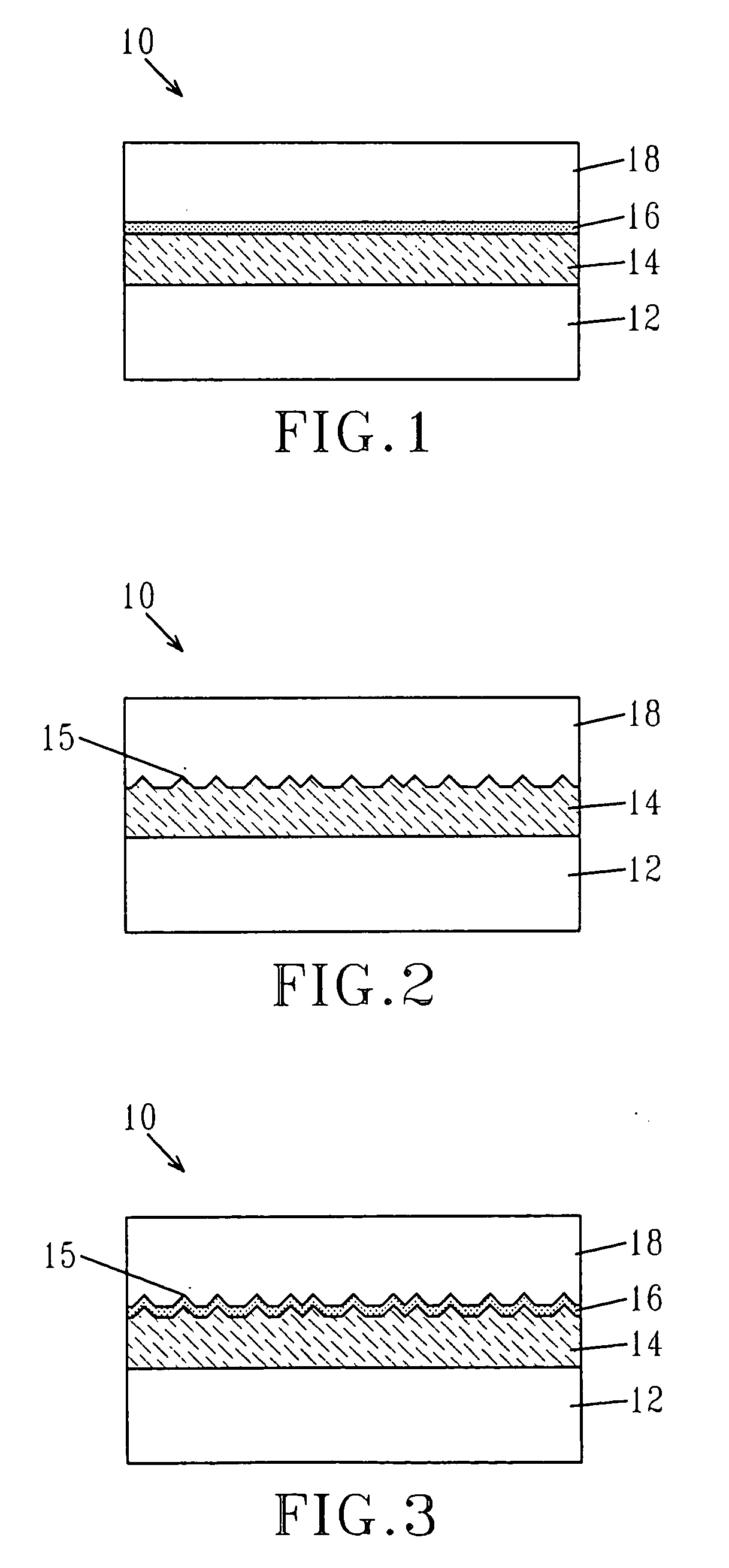

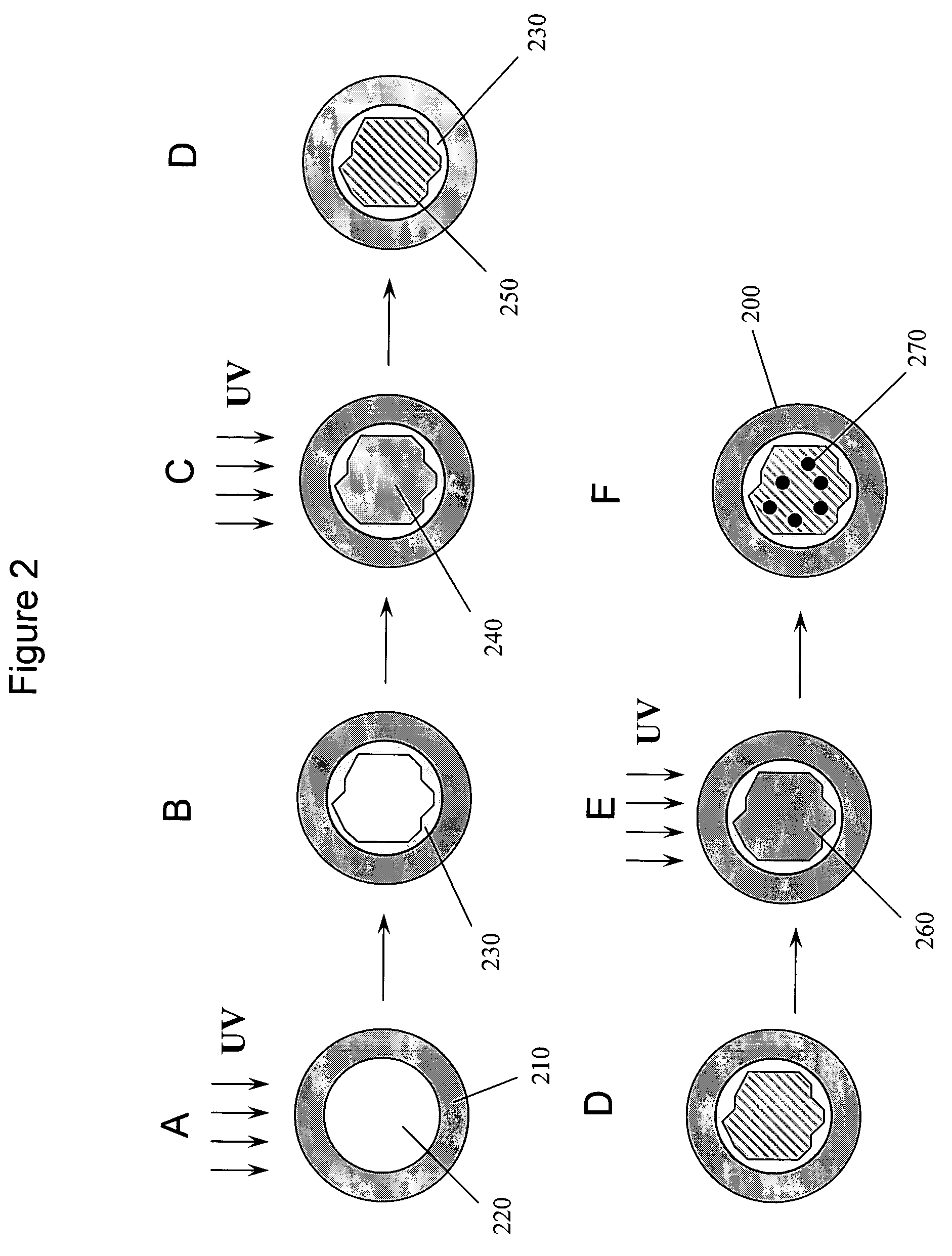

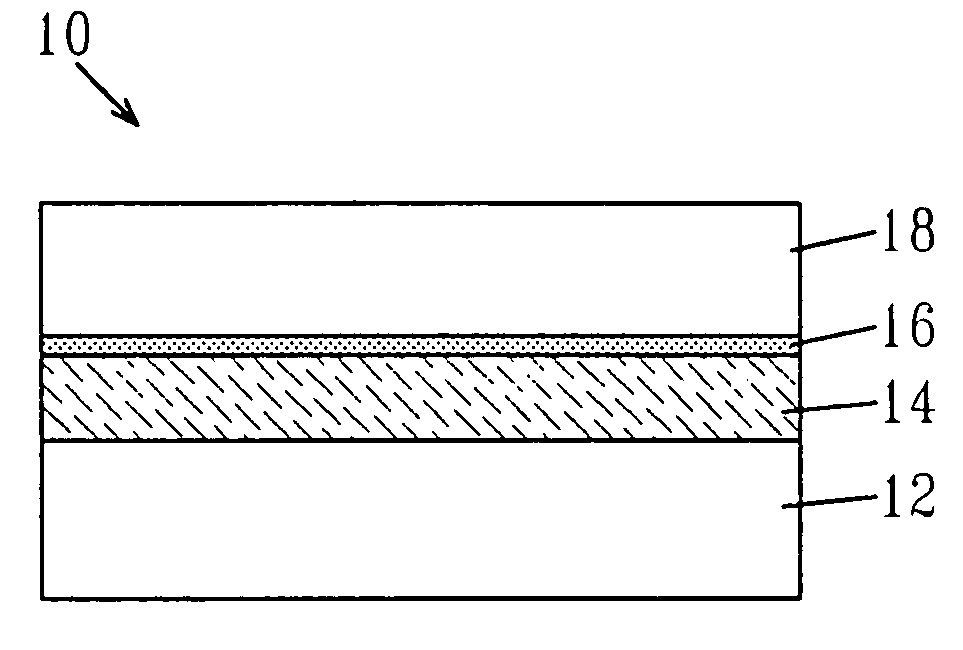

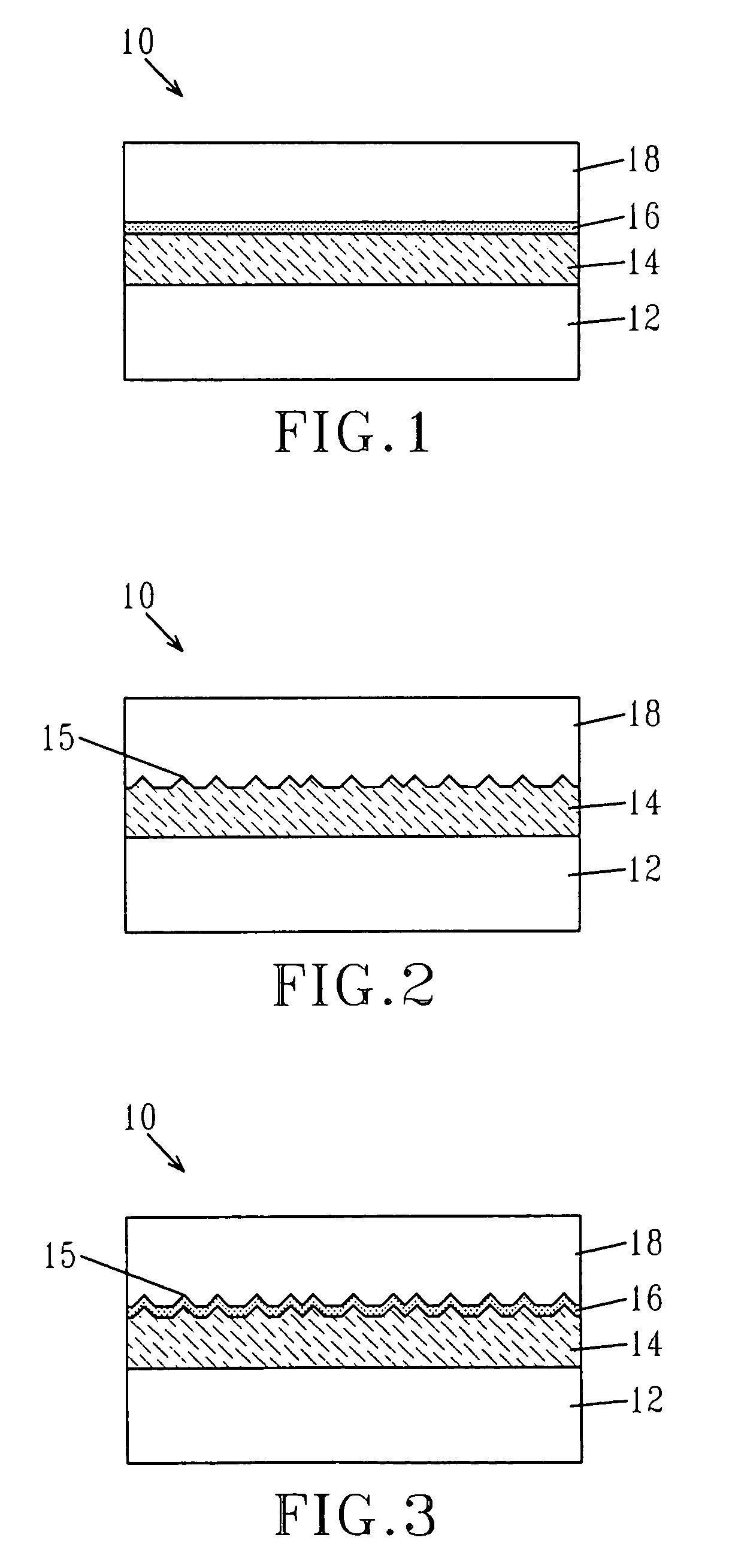

Method for fabricating SiGe-on-insulator (SGOI) and Ge-on-insulator (GOI) substrates

ActiveUS20050093100A1Effective absorption thickness of Ge-containing is therefore increasedLow wavelength dependenceSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsMaterials science

A method for fabricating germanium-on-insulator (GOI) substrate materials, the GOI substrate materials produced by the method and various structures that can include at least the GOI substrate materials of the present invention are provided. The GOI substrate material include at least a substrate, a buried insulator layer located atop the substrate, and a Ge-containing layer, preferably pure Ge, located atop the buried insulator layer. In the GOI substrate materials of the present invention, the Ge-containing layer may also be referred to as the GOI film. The GOI film is the layer of the inventive substrate material in which devices can be formed.

Owner:GLOBALFOUNDRIES US INC

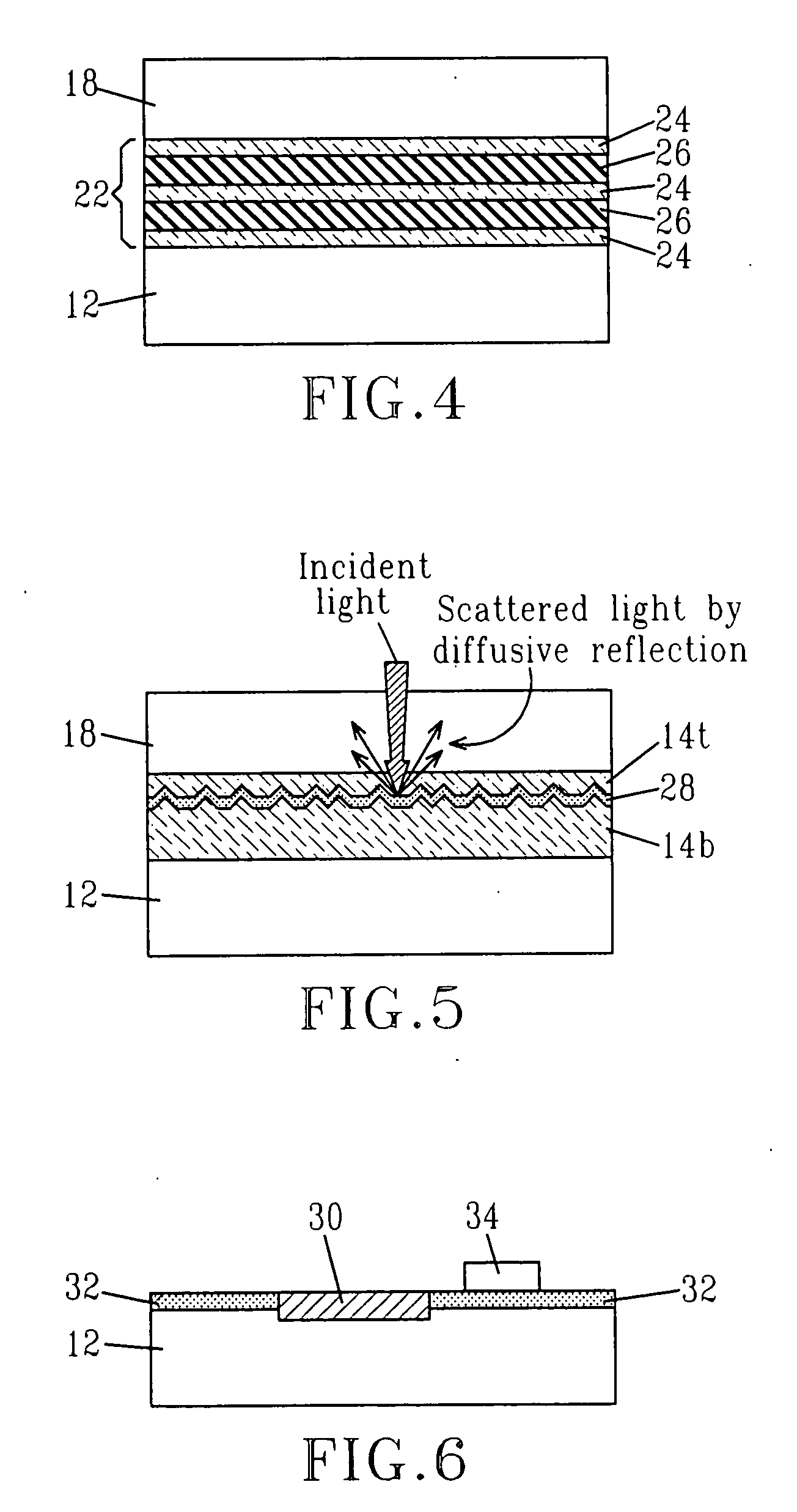

Photoinitiated grafting of porous polymer monoliths and thermoplastic polymers for microfluidic devices

InactiveUS7431888B2Preventing significant in performance of devicePoor bondingElectrolysis componentsVolume/mass flow measurementPolymer scienceThermosetting polymer

A microfluidic device preferably made of a thermoplastic polymer that includes a channel or a multiplicity of channels whose surfaces are modified by photografting. The device further includes a porous polymer monolith prepared via UV initiated polymerization within the channel, and functionalization of the pore surface of the monolith using photografting. Processes for making such surface modifications of thermoplastic polymers and porous polymer monoliths are set forth.

Owner:RGT UNIV OF CALIFORNIA

Process for producing capacitive electromechanical conversion device, and capacitive electromechanical conversion device

InactiveUS8665672B2Poor bondingBeacon systems using ultrasonic/sonic/infrasonic wavesWave amplification devicesBond interfaceEngineering

Owner:CANON KK

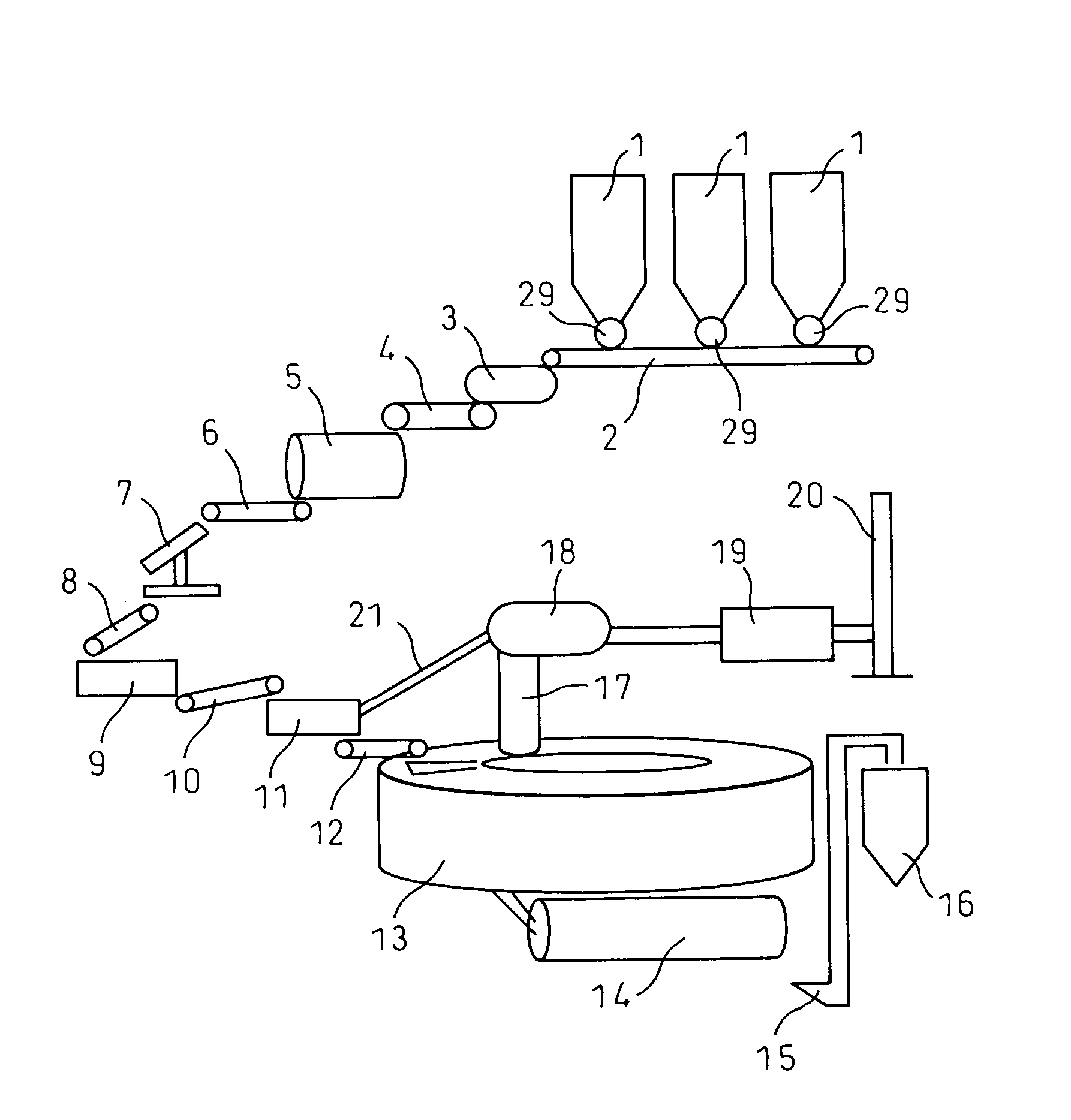

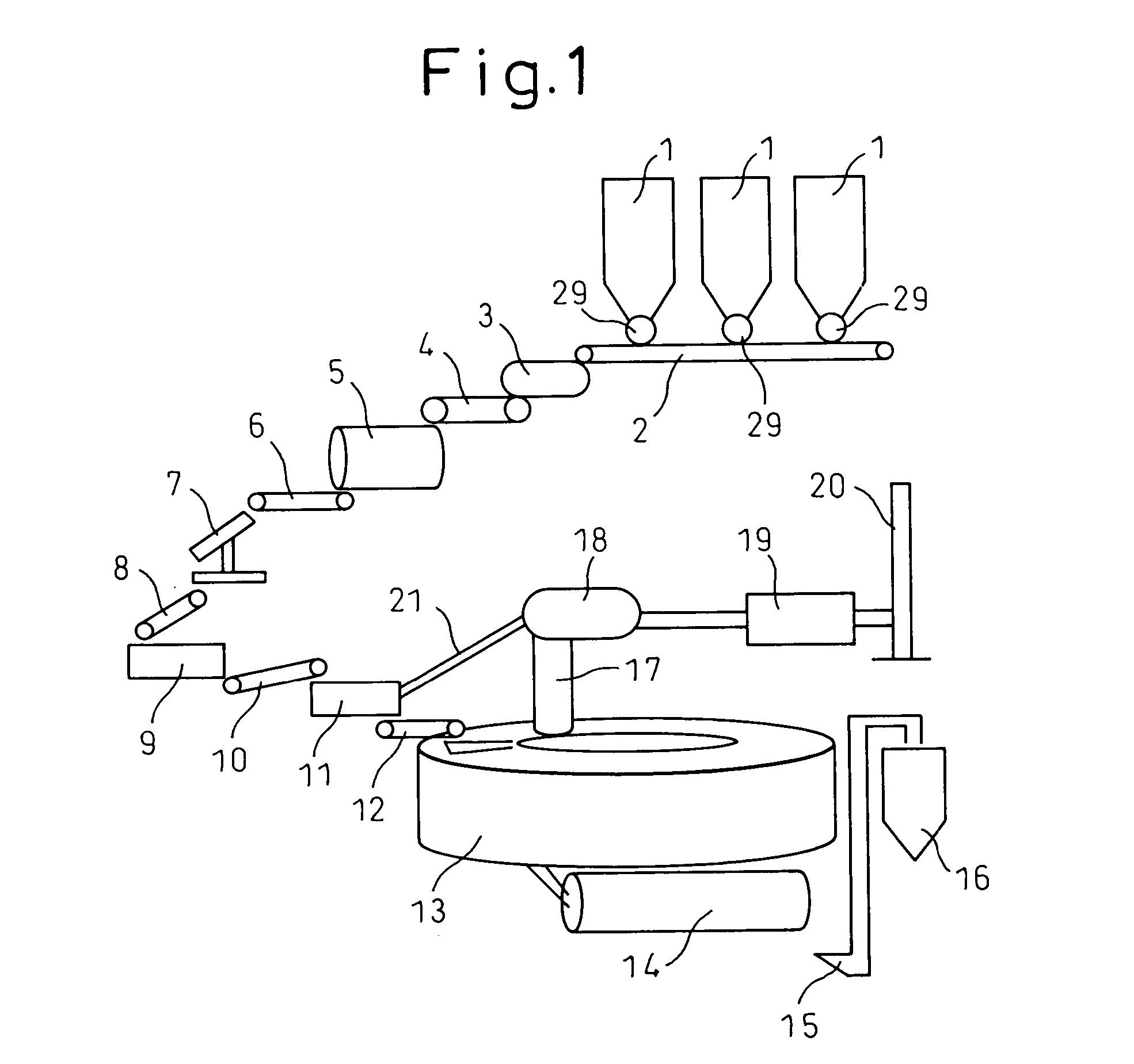

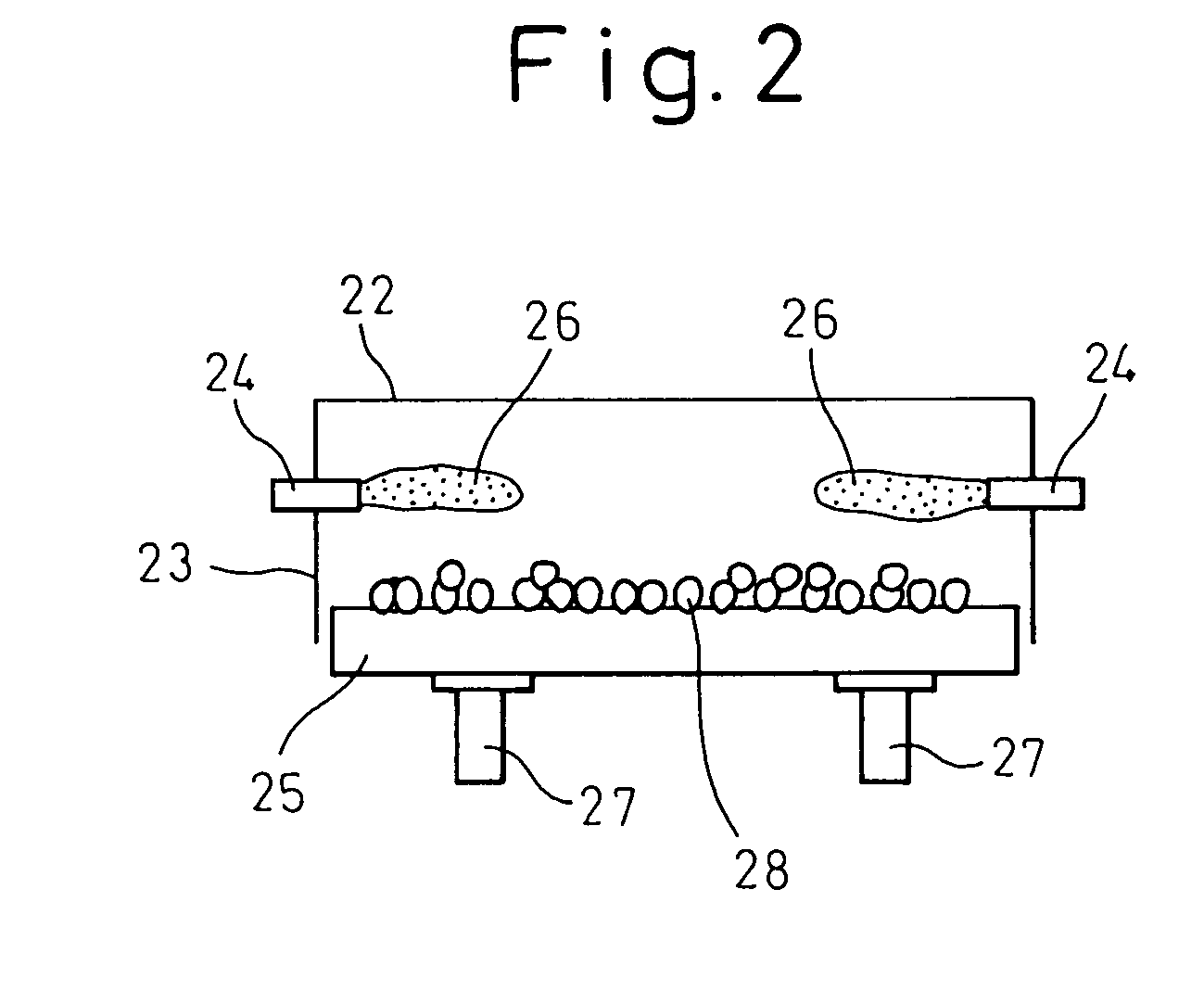

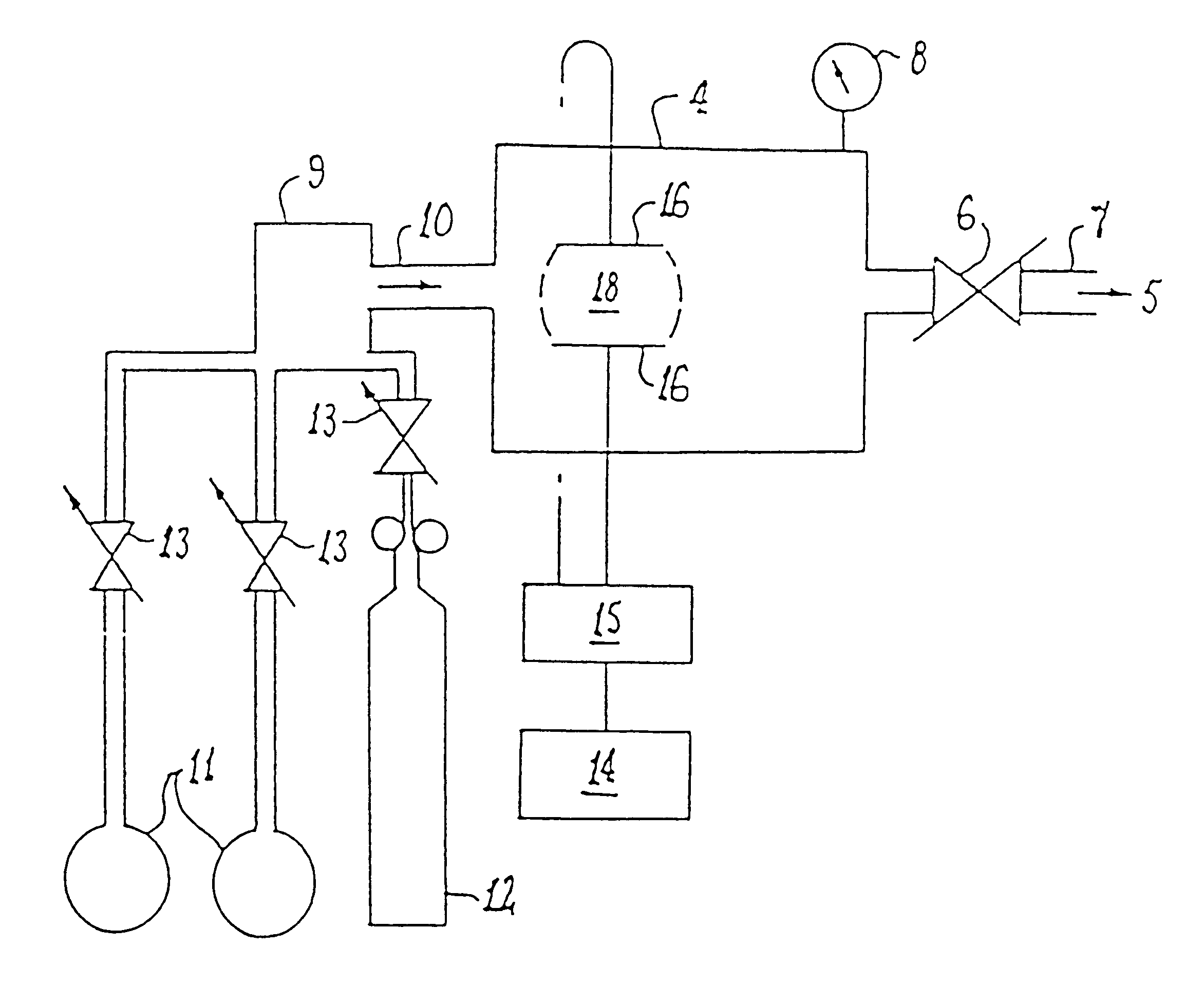

Metal oxide-containing green pellet for reducing furnace, method for production thereof, method of reduction thereof, and reduction facilities

InactiveUS20040020326A1High strengthHigh ratioBlast furnace componentsBlast furnace detailsOxideHigh intensity

The present invention provides a method and facility for preventing crumbling and powderization of green pellets when producing high strength green pellets using a powder feedstock and using the pellets in a rotary hearth reducing furnace and for efficiently reducing the same. It comprises kneading by a kneader 5 a feedstock of a powder of a fine particle size (20 to 80 wt % having size of not more than 10 mum) including a metal oxide and carbon-bearing powder fed from a feed storage tank 1 and producing green pellets by a pan type pelletized 7. The green pellets are screened by a pellet screen 9, then dried by a pellet dryer 11 and reduced by firing in a rotary hearth reducing furnace 13. At that time, the green pellets are continuously conveyed to prevent crumbling.

Owner:NIPPON STEEL CORP

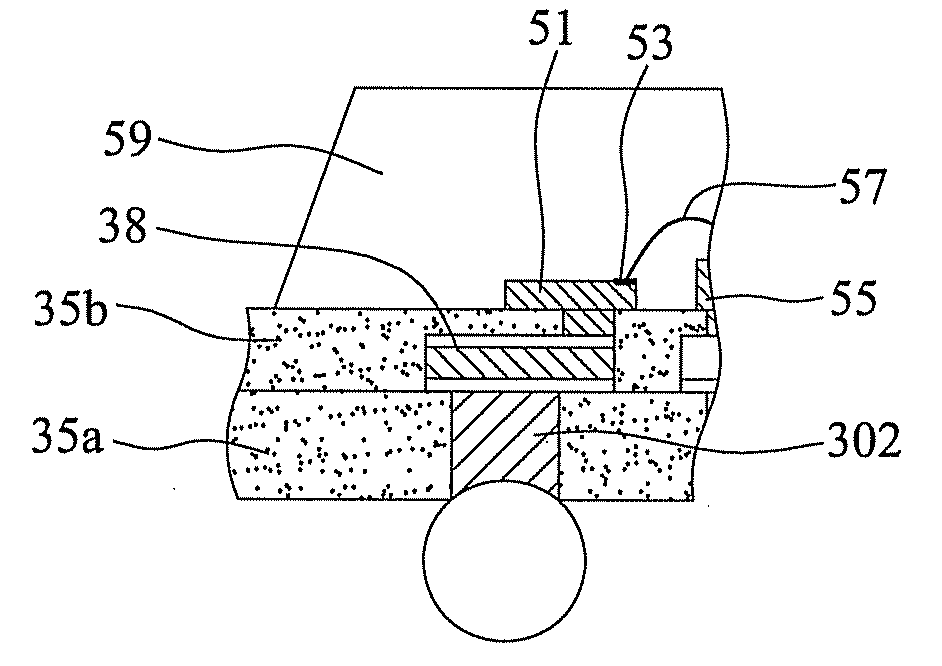

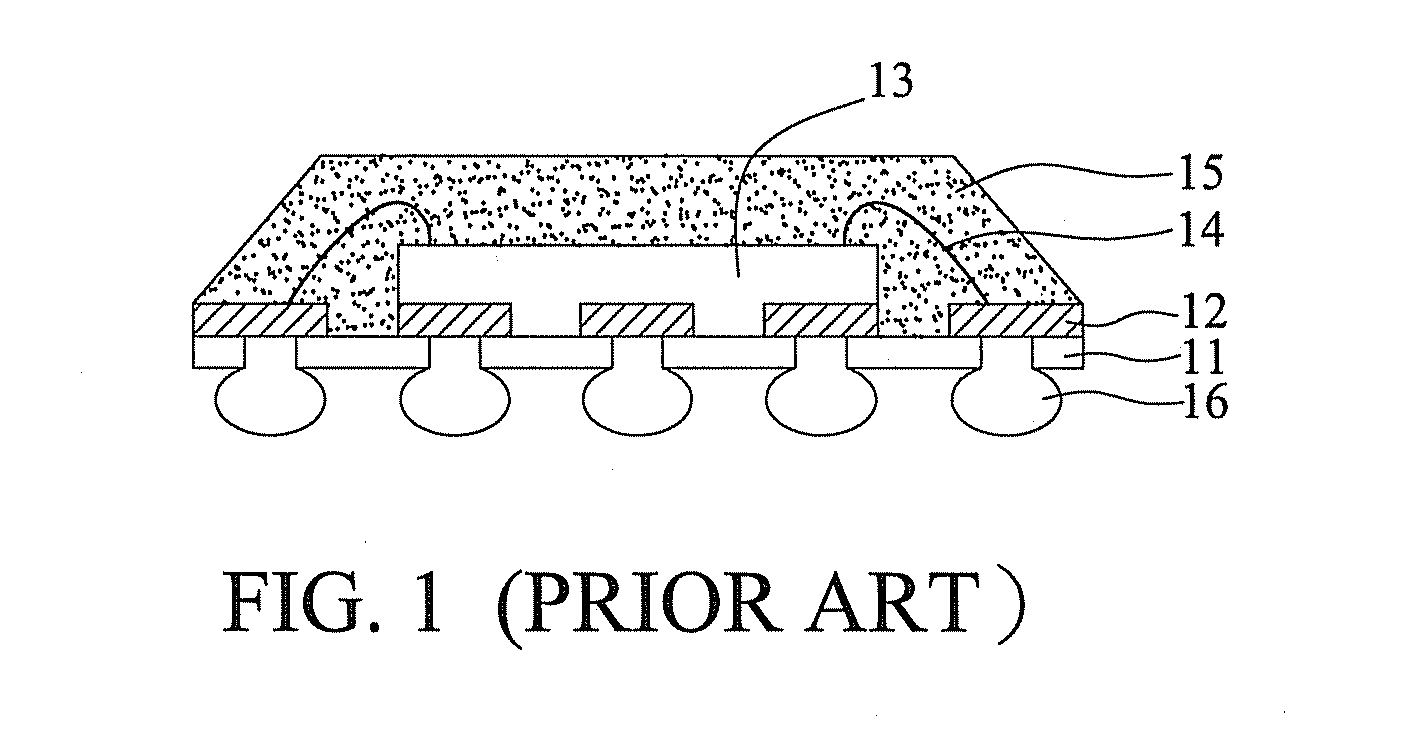

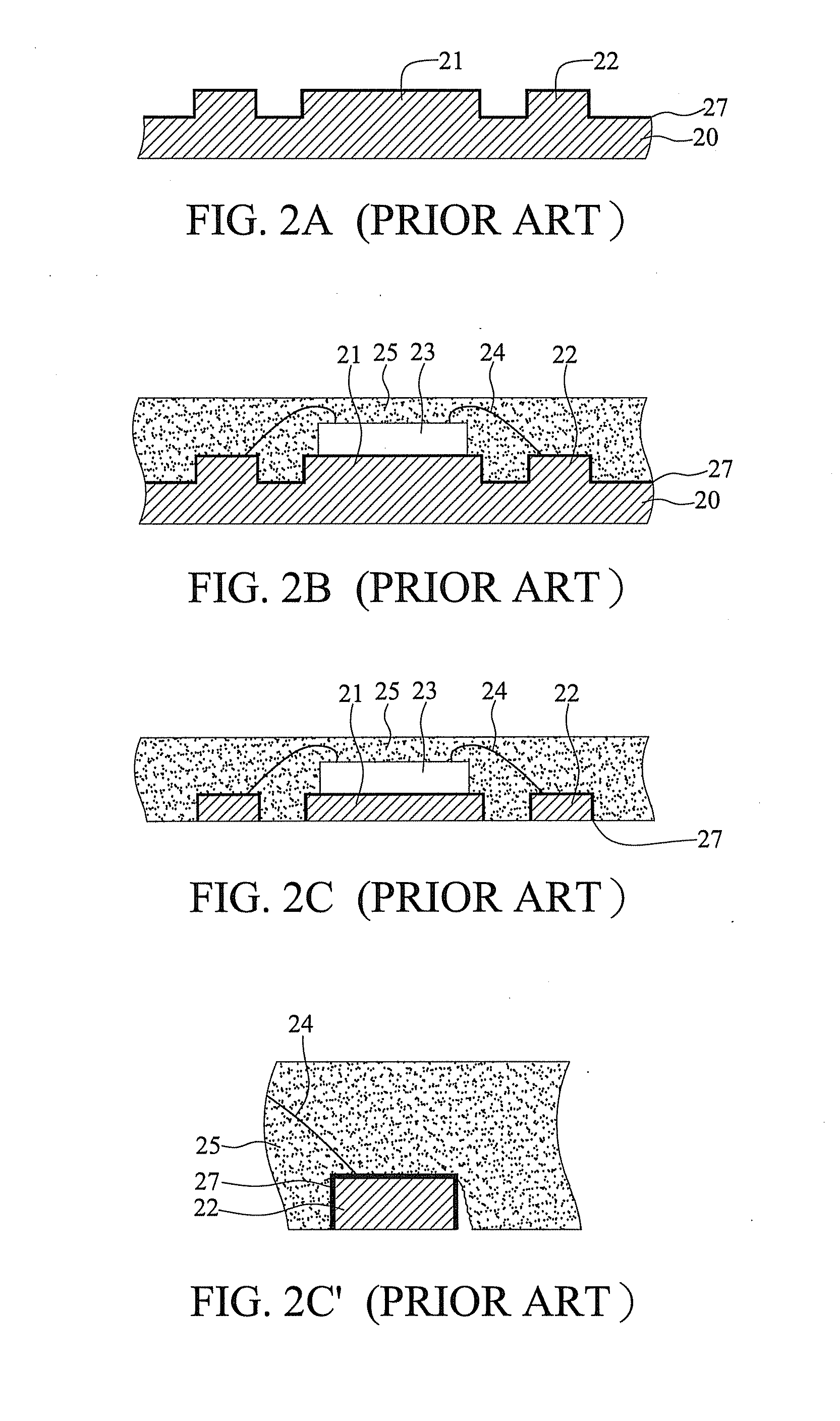

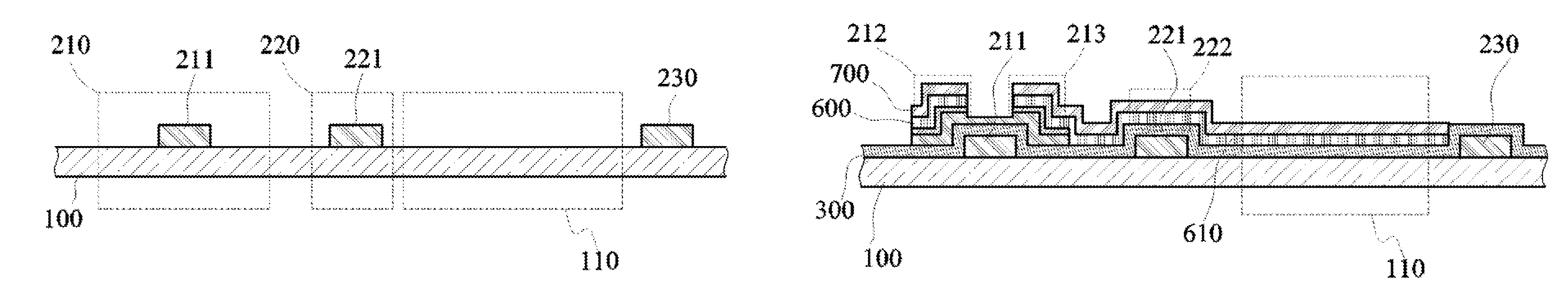

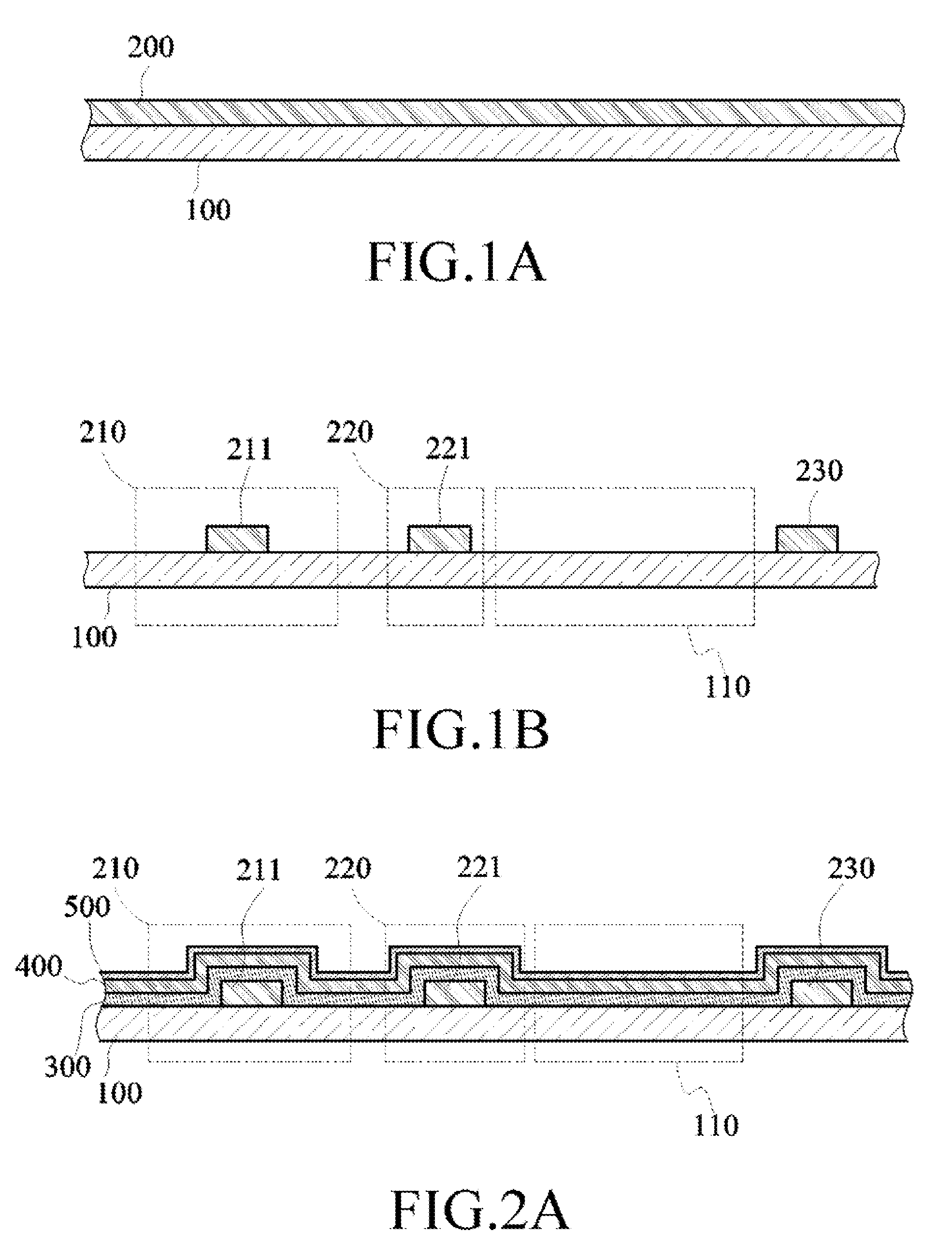

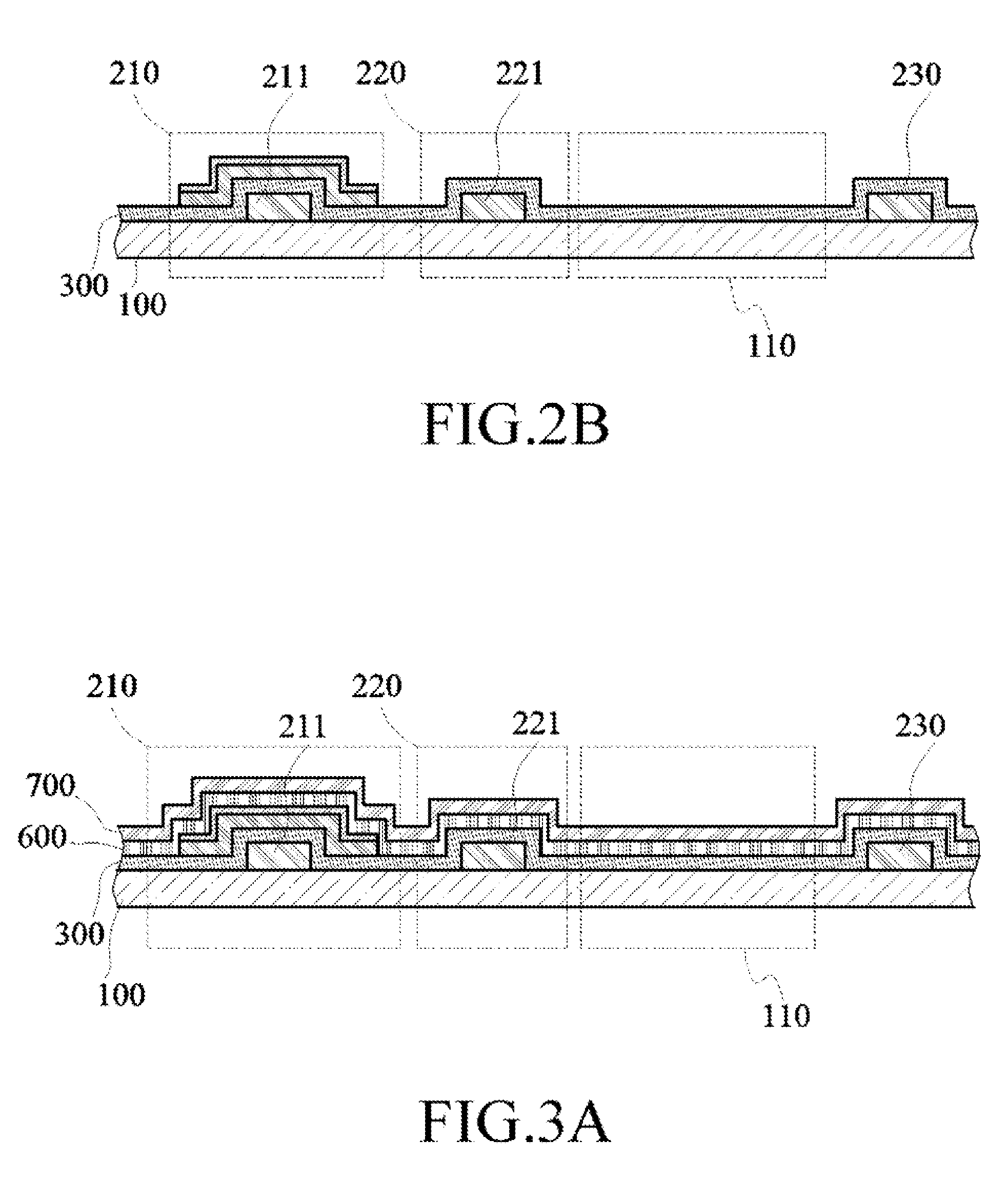

Semiconductor package without chip carrier and fabrication method thereof

ActiveUS20120007234A1Reduce manufacturing costAvoid layeringSemiconductor/solid-state device detailsSolid-state devicesResistLead bonding

A semiconductor package without a chip carrier formed thereon and a fabrication method thereof. A metallic carrier is half-etched to form a plurality of grooves and metal studs corresponding to the grooves. The grooves are filled with a first encapsulant and a plurality of bonding pads are formed on the metal studs. The first encapsulant is bonded with the metal studs directly. Each of the bonding pads and one of the metal studs corresponding to the bonding pad form a T-shaped structure. Therefore, bonding force between the metal studs and the first encapsulant is enhanced such that delamination is avoided. Die mounting, wire-bonding and molding processes are performed subsequently. Since the half-etched grooves are filled with the first encapsulant, the drawback of having pliable metallic carrier that makes transportation difficult to carry out as encountered in prior techniques is overcome, and the manufacturing cost is educed by not requiring the use of costly metals as an etching resist layer.

Owner:SILICONWARE PRECISION IND CO LTD

Method for fabricating SiGe-on-insulator (SGOI) and Ge-on-insulator (GOI) substrates

InactiveUS7084460B2High bonding strengthPoor bondingSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsGermanium

A method for fabricating germanium-on-insulator (GOI) substrate materials, the GOI substrate materials produced by the method and various structures that can include at least the GOI substrate materials of the present invention are provided. The GOI substrate material include at least a substrate, a buried insulator layer located atop the substrate, and a Ge-containing layer, preferably pure Ge, located atop the buried insulator layer. In the GOI substrate materials of the present invention, the Ge-containing layer may also be referred to as the GOI film. The GOI film is the layer of the inventive substrate material in which devices can be formed.

Owner:GLOBALFOUNDRIES US INC

Display panel and production method thereof

ActiveUS8884849B2Improve deteriorationReduced Surface Flatness RequirementsStatic indicating devicesElectroluminescent light sourcesHermetic sealFrit

A display panel includes: a first substrate; light-emitting elements on a region of the first substrate; a second substrate facing the first substrate with the light-emitting elements therebetween; a glass frit between the first substrate and the second substrate so as to surround the region of the first substrate in which the light-emitting elements are disposed, the glass frit providing a hermetic seal between the first substrate and the second substrate; and a light-shielding part formed on one of the first substrate and the second substrate so as to extend along the glass frit, the light-shielding part shielding light. The light-shielding part has a lower light-shielding property in a region corresponding to the outer region of the glass frit than in a region corresponding to the inner region of the glass frit. The glass frit has been irradiated with light through the light-shielding part.

Owner:JOLED INC

Surface modification of polymers

InactiveUS6299787B1Poor bondingHigh bonding strengthLamination ancillary operationsDecorative surface effectsPolymer scienceFluorinated polymer

A method of providing adhesion to a fluorinated polymer including exposing at least a portion of the surface of the fluorinated polymer to plasma discharge in an atmosphere containing an organic amine.

Owner:COMMONWEALTH SCI & IND RES ORG

Shaped nanoporous bodies

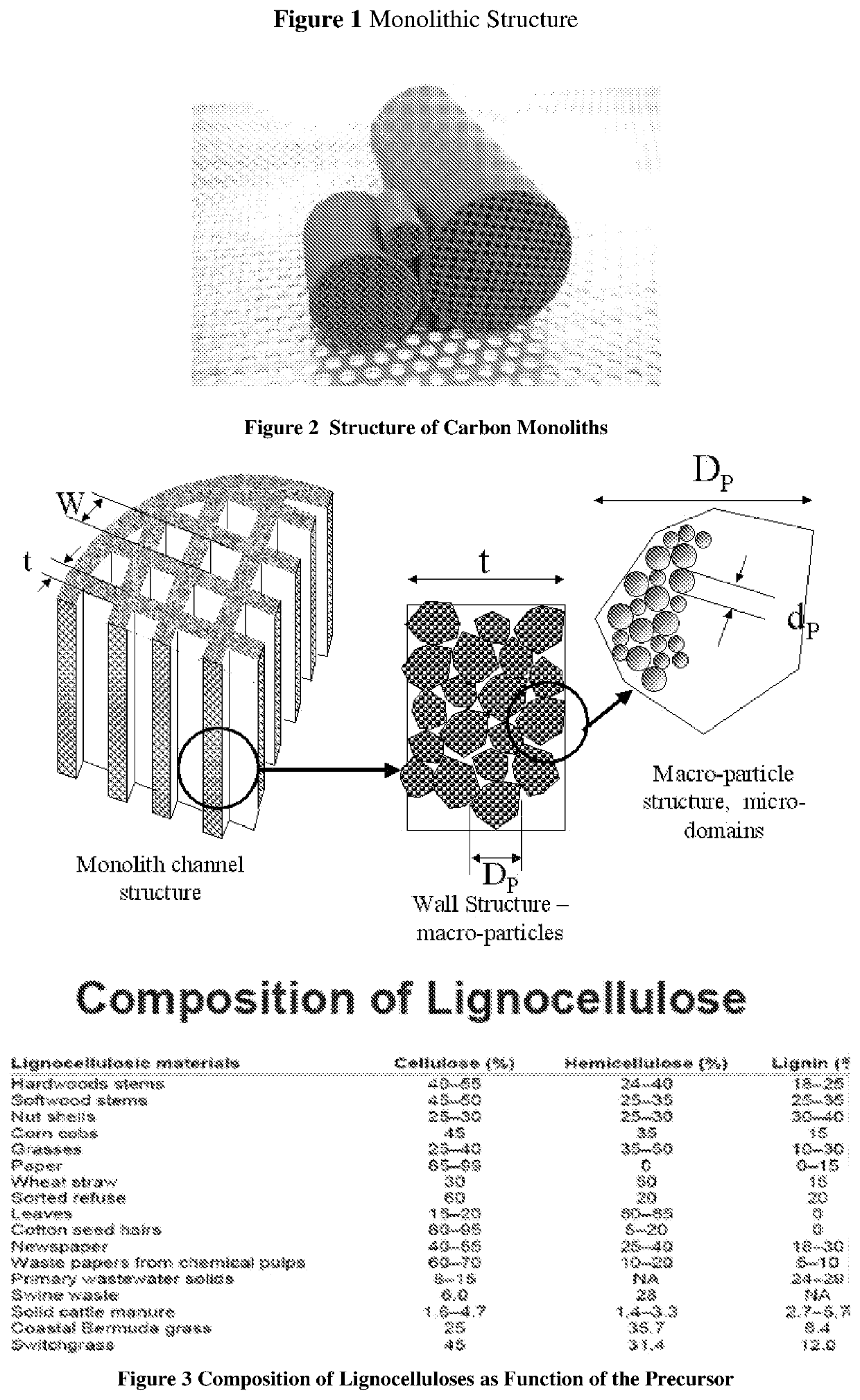

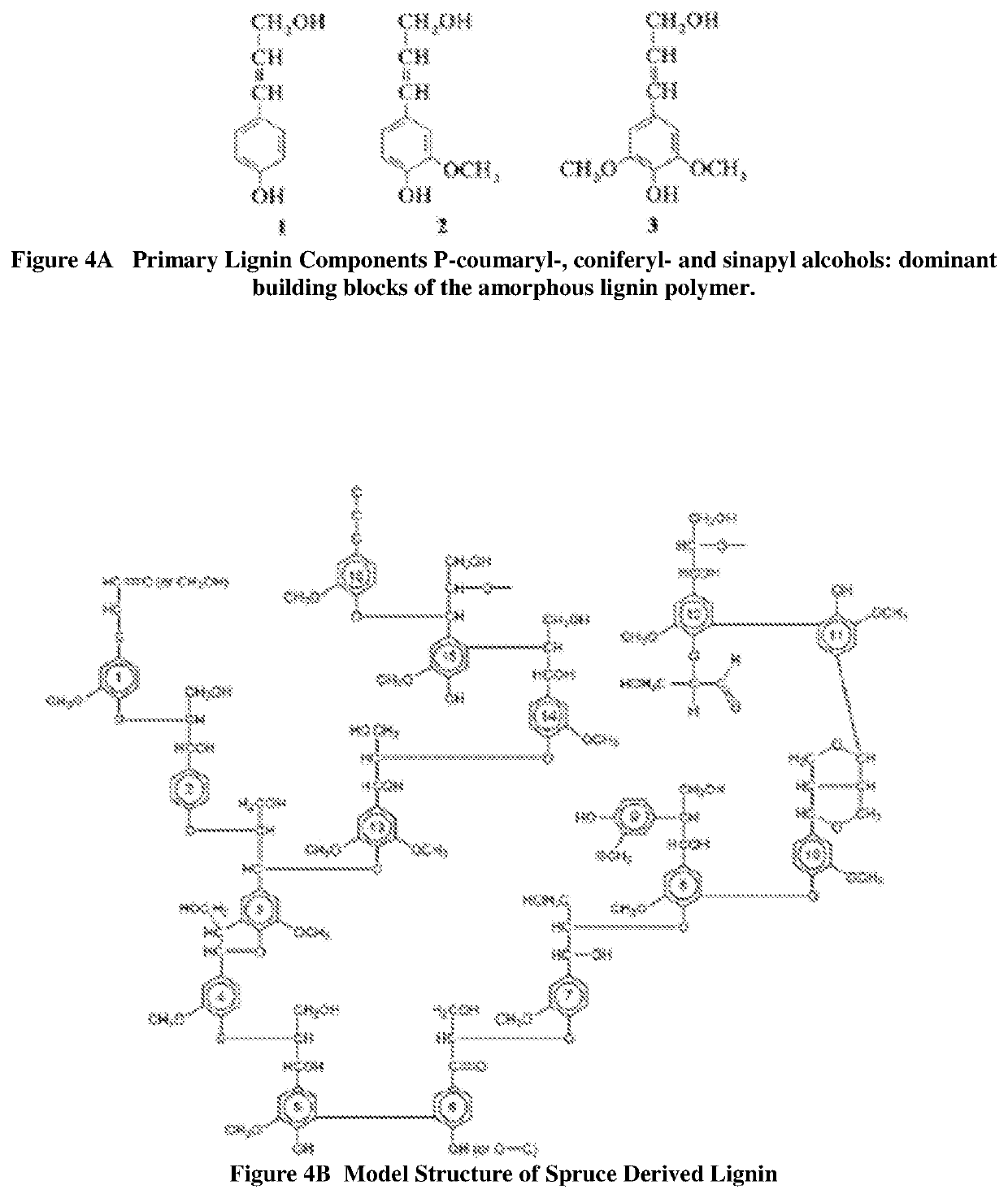

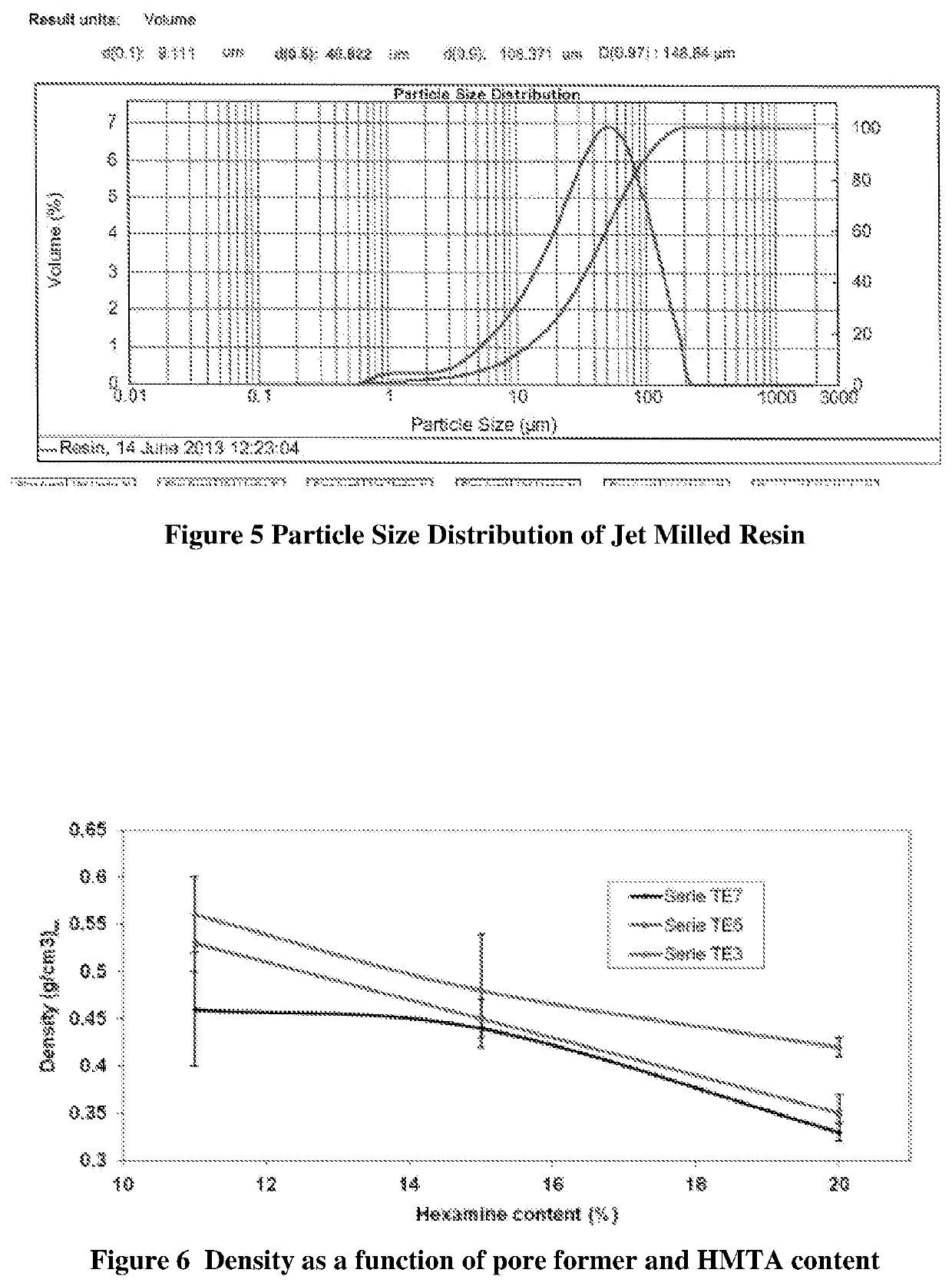

ActiveUS20190022623A1Preventing in use leakagePrevent escapeCarbon compoundsOther chemical processesCellulosePorous carbon

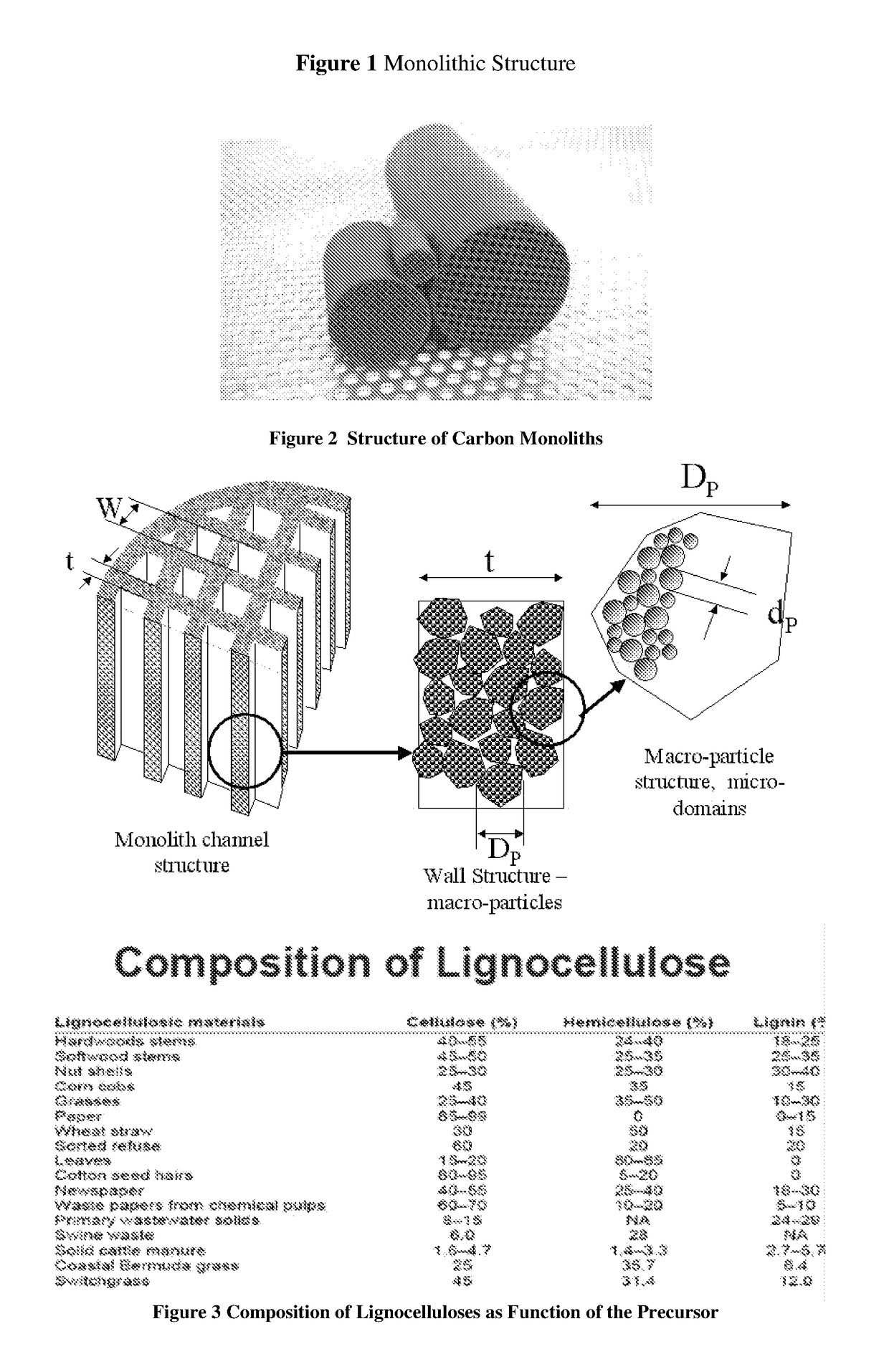

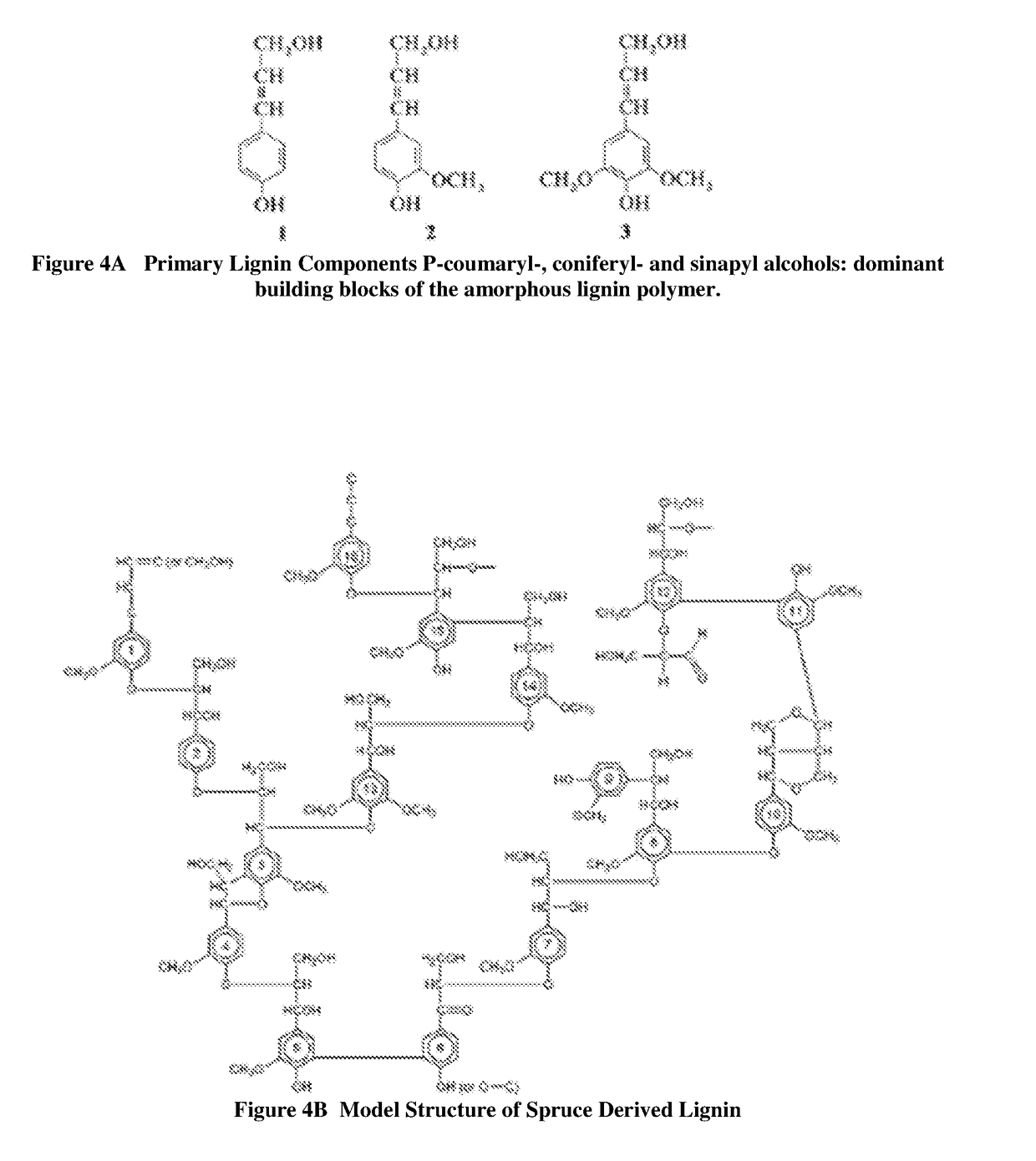

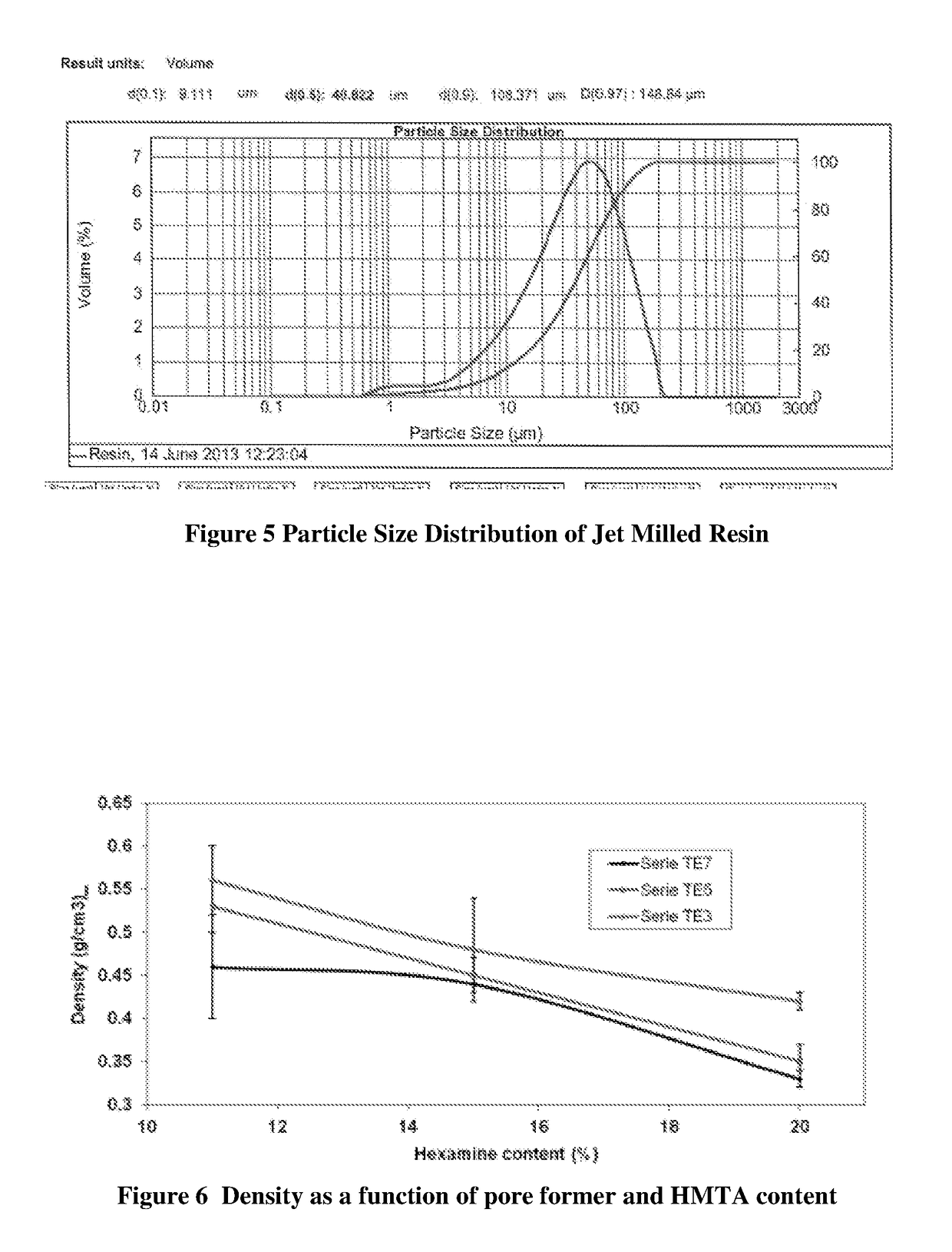

A range of carbon materials can be produced using lignin in combination with synthetic phenolic resins or naturally occurring lingo-cellulosic materials. The lignin, which is essentially a naturally occurring phenolic resin, has a carbon yield on pyrolysis similar to that of the synthetic resins, which aids processing. The lignin can be used as a binder phase for synthetic resin or lignocellulosic materials allowing the production of monolithic carbons from a wide range of precursors, as the primary structural material where the thermal processing is modified by the addition of small quantities of synthetic resin materials or as structure modified in the production of meso / macro porous carbons in either bead, granular or monolithic form. A carbonised monolith is provided comprising mesoporous and / or macroporous carbon particles dispersed in a matrix of microporous carbon particles with voids between the particles defining paths for fluid to flow into and through the structure. The monolith may take the form of a shaped body having walls defining a multiplicity of internal transport channels for fluid flow, the transport channels being directed along the extrusion direction. The monolith may be made by carbonising a shaped phenolic body based on phenolic resin precursors. In a method for producing such a carbonisable shaped resin body solid particles of a first phenolic resin are provided which is partially cured so that the particles are sinterable but do not melt on carbonisation. The particles of the first phenolic resin are mixed with particles of a second phenolic resin that has a greater degree of cure than said first phenolic resin and has a mesoporous and / or macroporous microstructure that is preserved on carbonisation. The resulting mixture is formed into a dough e.g. by mixing the resin particles with methyl cellulose, PEO and water, after which the dough is extruded to form a shaped product and stabilising in its shape by sintering.

Owner:NEOTERYX

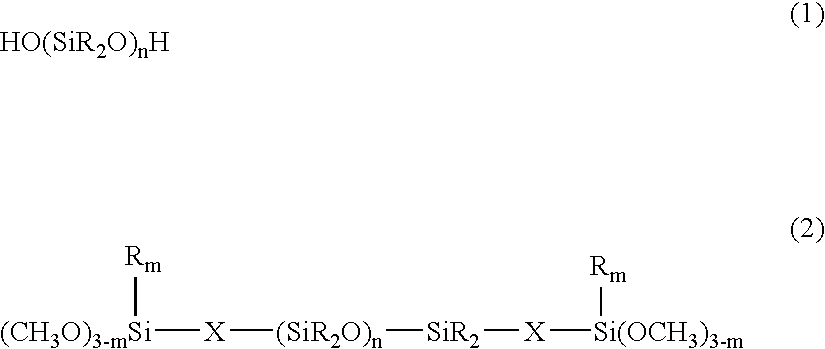

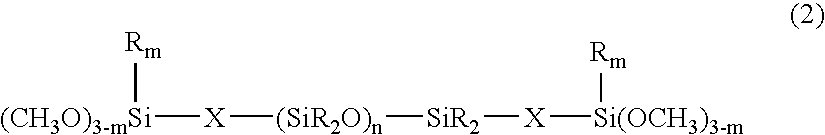

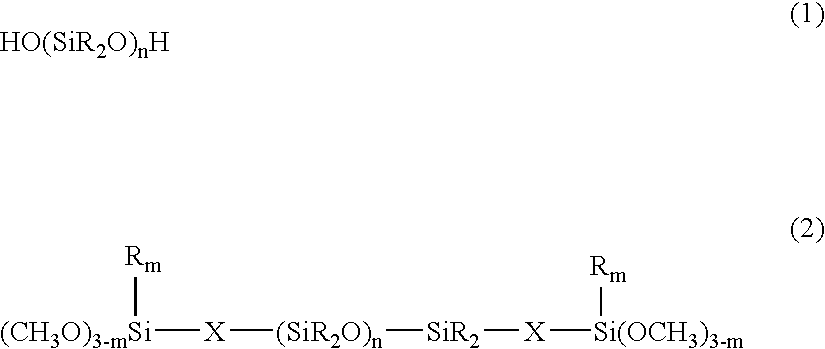

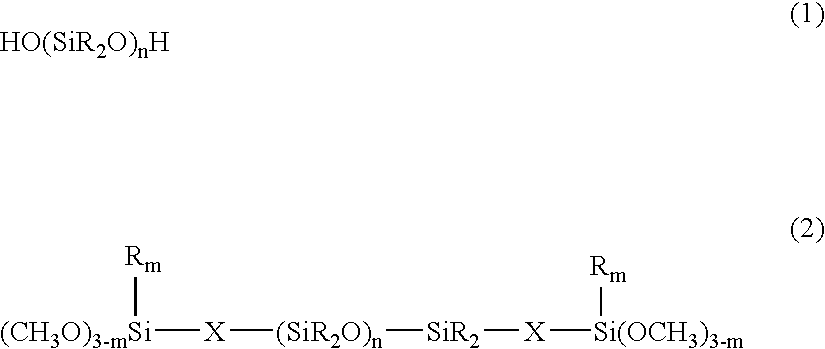

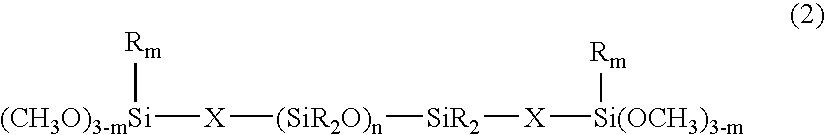

Organopolysiloxane composition for bonding to magnesium alloy

ActiveUS20050228091A1Good self-adhesivenessGood self-adhesiveNon-macromolecular adhesive additivesSpecial tyresOxygen atomSilane coupling

An organopolysiloxane composition for bonding to magnesium alloys comprises (A) 100 parts by weight of an organopolysiloxane of the following general formula (1) and / or (2) wherein R may be the same or different and represents a substituted or unsubstituted monovalent hydrocarbon group having 1 to 10 carbon atoms, and n is an integer of at least 10, X represents an oxygen atom or an alkylene group having 2 to 5 carbon atoms, and m independently represents an integer of 0 or 1, (B) 0.1 to 50 parts by weight of an organosilicon compound having at least three hydrolyzable groups bonded to silicon atoms in one molecule and / or a partial hydrolyzate thereof, and (C) 0.1 to 15 parts by weight of an acidic silane coupling agent.

Owner:SHIN ETSU CHEM IND CO LTD

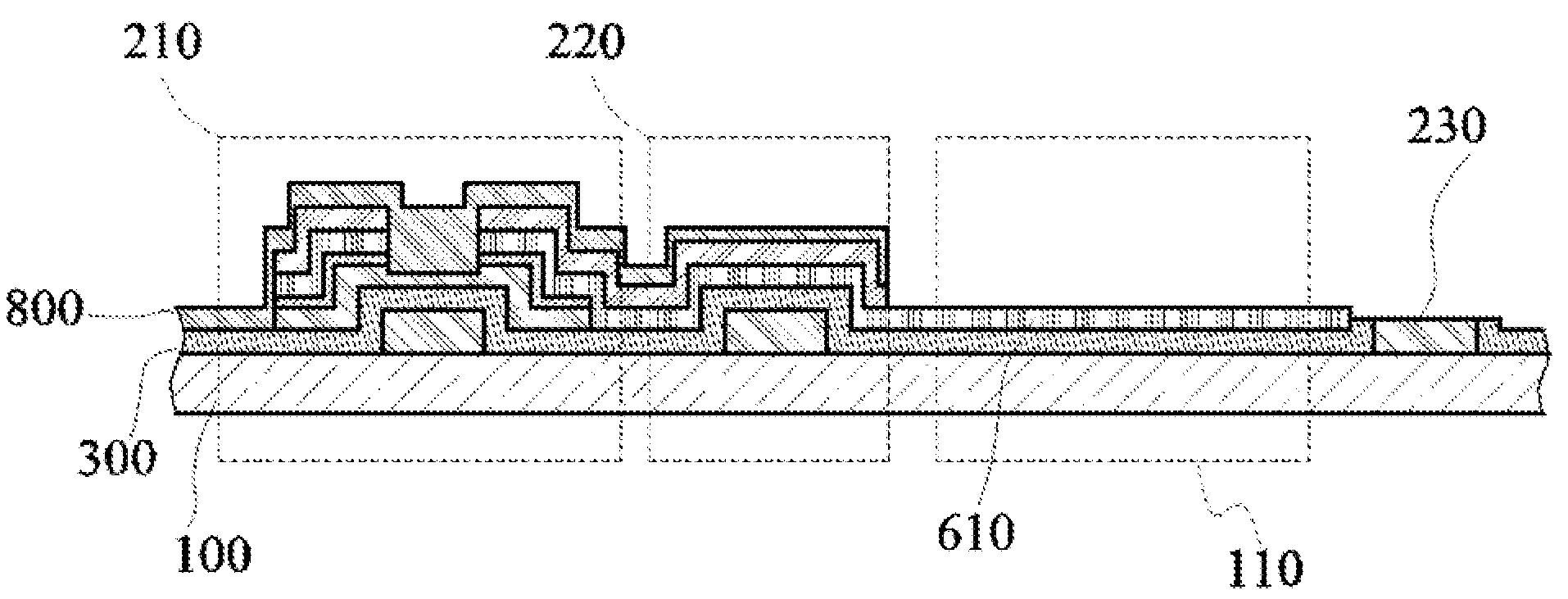

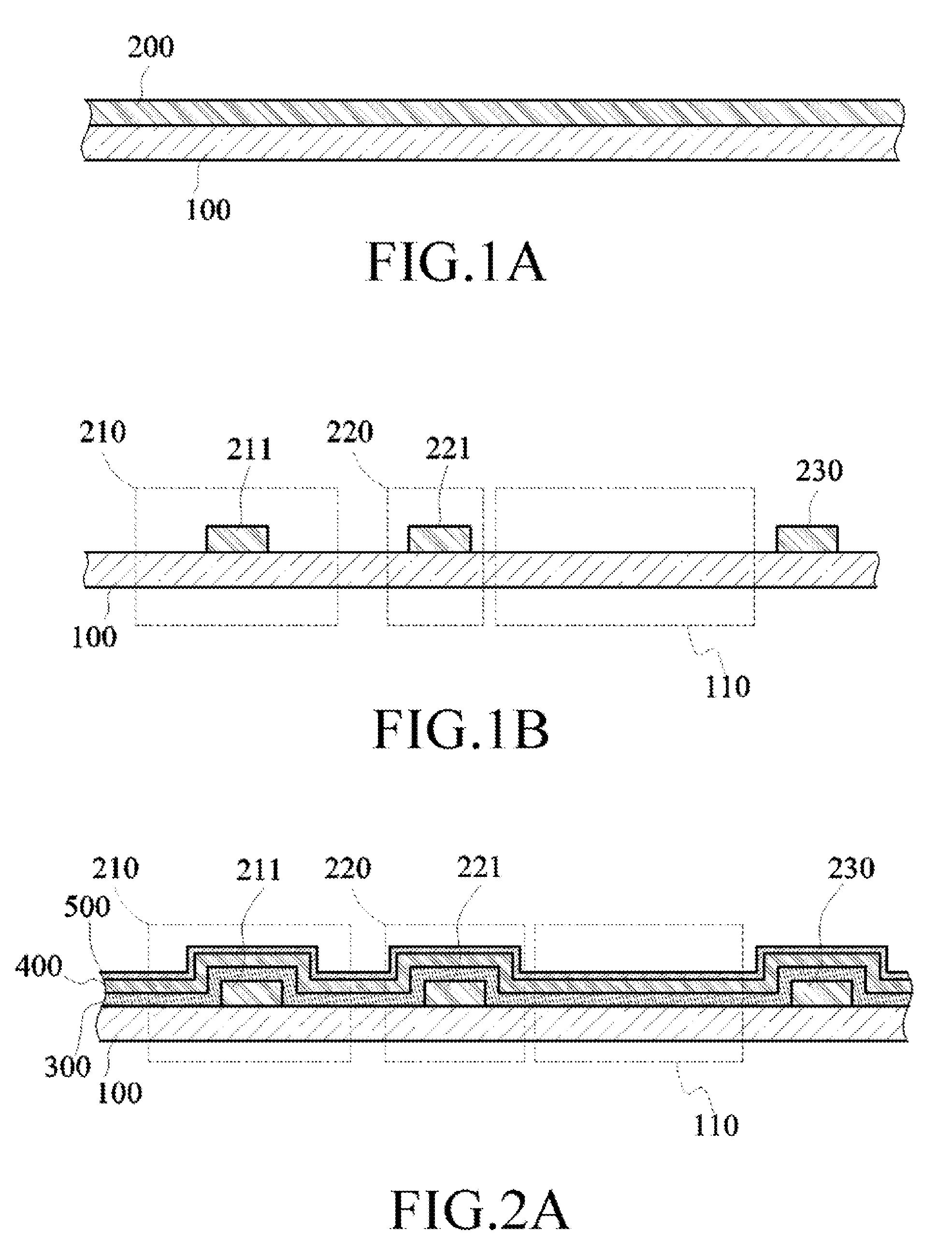

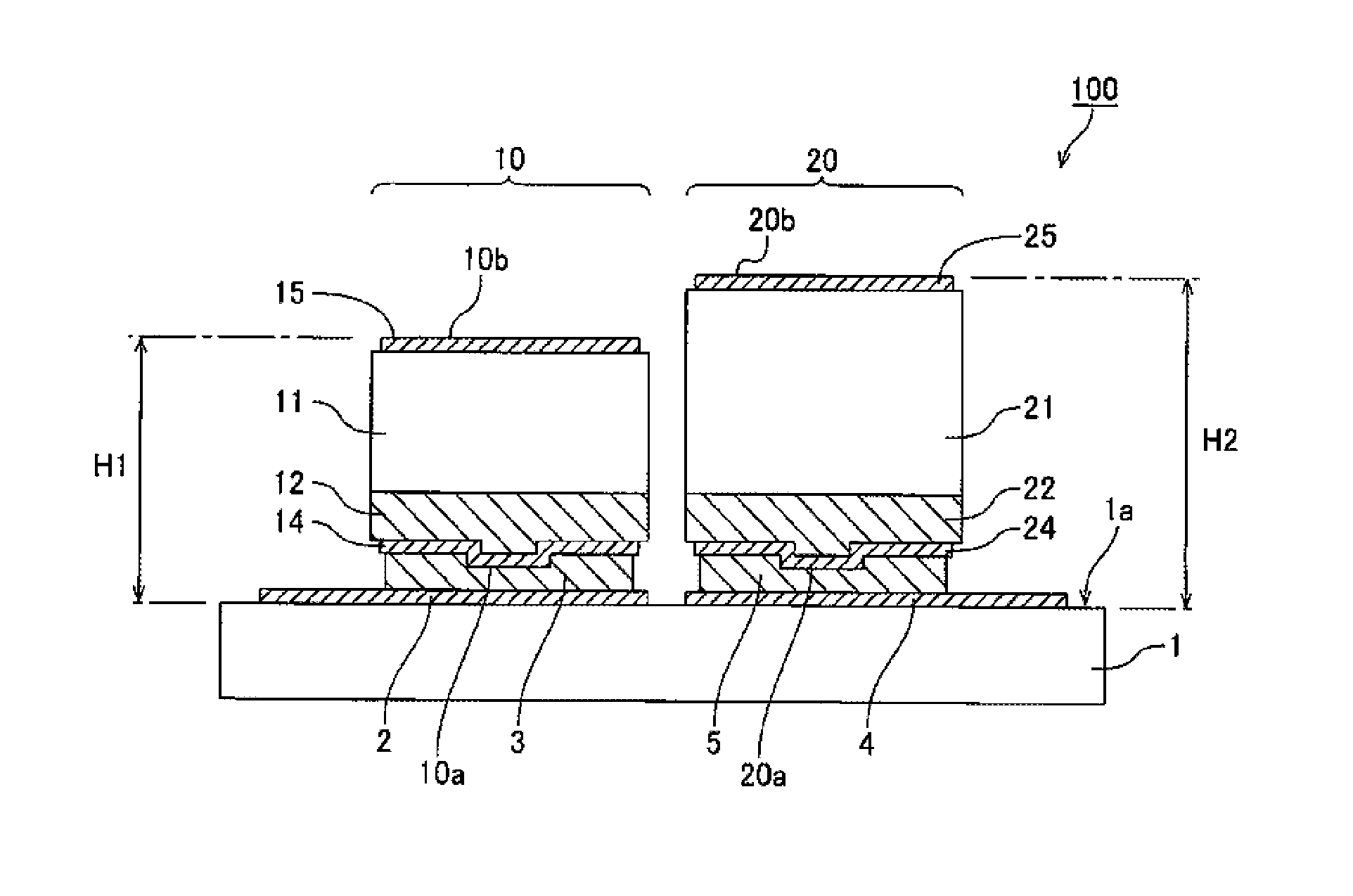

Thin Film Transistor Array Panel of Active Liquid Crystal Display and Fabrication Method Thereof

InactiveUS20080121885A1Lower impedanceEasy to operateSolid-state devicesSemiconductor/solid-state device manufacturingEtchingLiquid-crystal display

A thin film transistor (TFT) array panel structure and a fabrication method thereof are provided. The method includes the following steps. An insulating substrate is provided, on which a first metal layer is deposited to form a plurality of gate electrodes, a plurality of lower electrodes of storage capacitors, a plurality of scan lines, and a plurality of scan line pads with a first mask process. A TFT island region is formed with a second mask process. Drain electrodes and source electrodes of the TFT, upper electrodes of storage capacitors, pixel electrodes, data lines and data line pads are formed, and a plurality of pixel display regions is defined with a third mask process. The pattern of a passivation layer is defined with a fourth mask. A second metal layer in the pixel display region is removed by selective etching.

Owner:WINTEK CORP

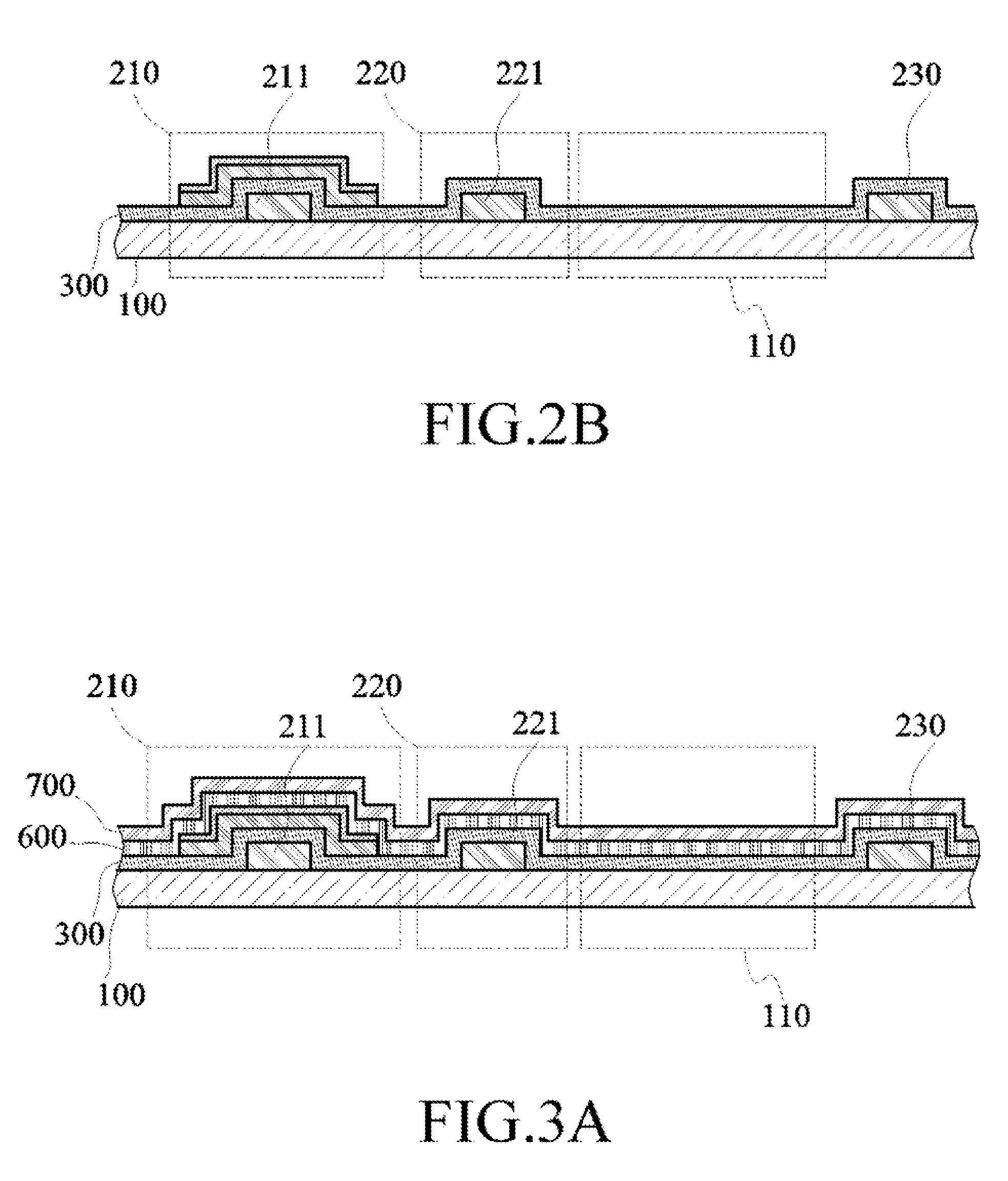

Semiconductor laser apparatus, method of manufacturing the same and optical apparatus

InactiveUS20110007771A1Improve adhesionPoor bondingOptical wave guidanceSemiconductor laser arrangementsSemiconductorLaser

This semiconductor laser apparatus includes a support member having a main surface, a first semiconductor laser device bonded onto the main surface through a first bonding layer and a second semiconductor laser device bonded onto the main surface through a second bonding layer to be adjacent to the first semiconductor laser device. The melting point of the second bonding layer is lower than that of the first bonding layer, and a first height from the main surface to a fourth surface of the second semiconductor laser device is larger than a second height from the main surface to a second surface of the first semiconductor laser device.

Owner:SANYO ELECTRIC CO LTD

Optical fiber manufacturing apparatus and optical fiber manufacturing method

ActiveUS20100139323A1Increased freedom of deformationDamage suppressionGlass fibre drawing apparatusMechanical engineeringOptical fiber cable

An optical fiber manufacturing apparatus for manufacturing an optical fiber by drawing a optical fiber preform, including: a drawing furnace having therein a muffle tube into which the optical fiber preform is inserted and heating the optical fiber preform; and a first seal member which is disposed at an insert side of the drawing furnace so as to be coaxial with the drawing furnace and which seals the optical fiber preform inserted into an opening formed at the center thereof, wherein the first seal member includes a plurality of inner-circumference slits formed in the inner circumference thereof and a plurality of outer-circumference slits formed in the outer circumference thereof.

Owner:THE FUJIKURA CABLE WORKS LTD

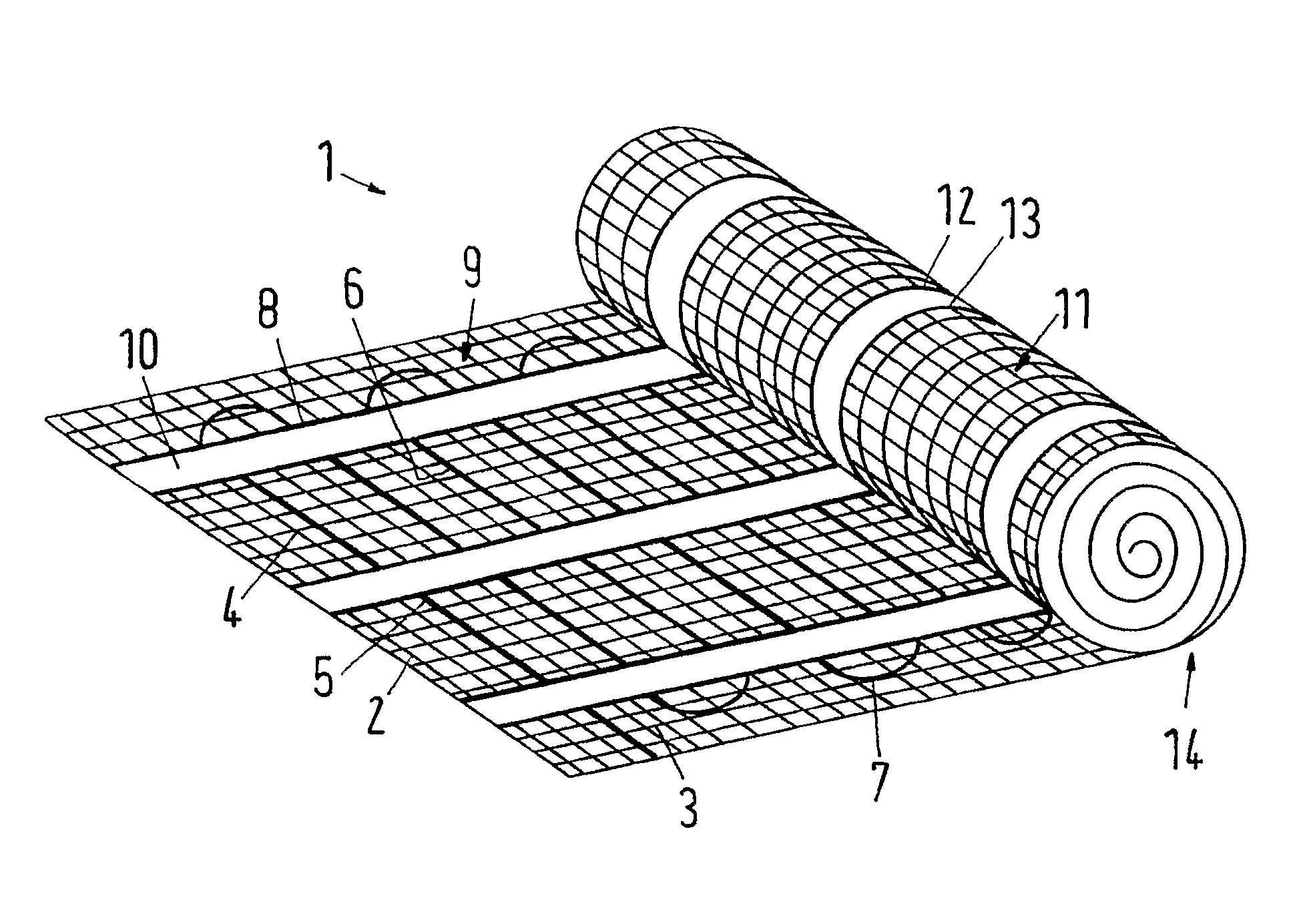

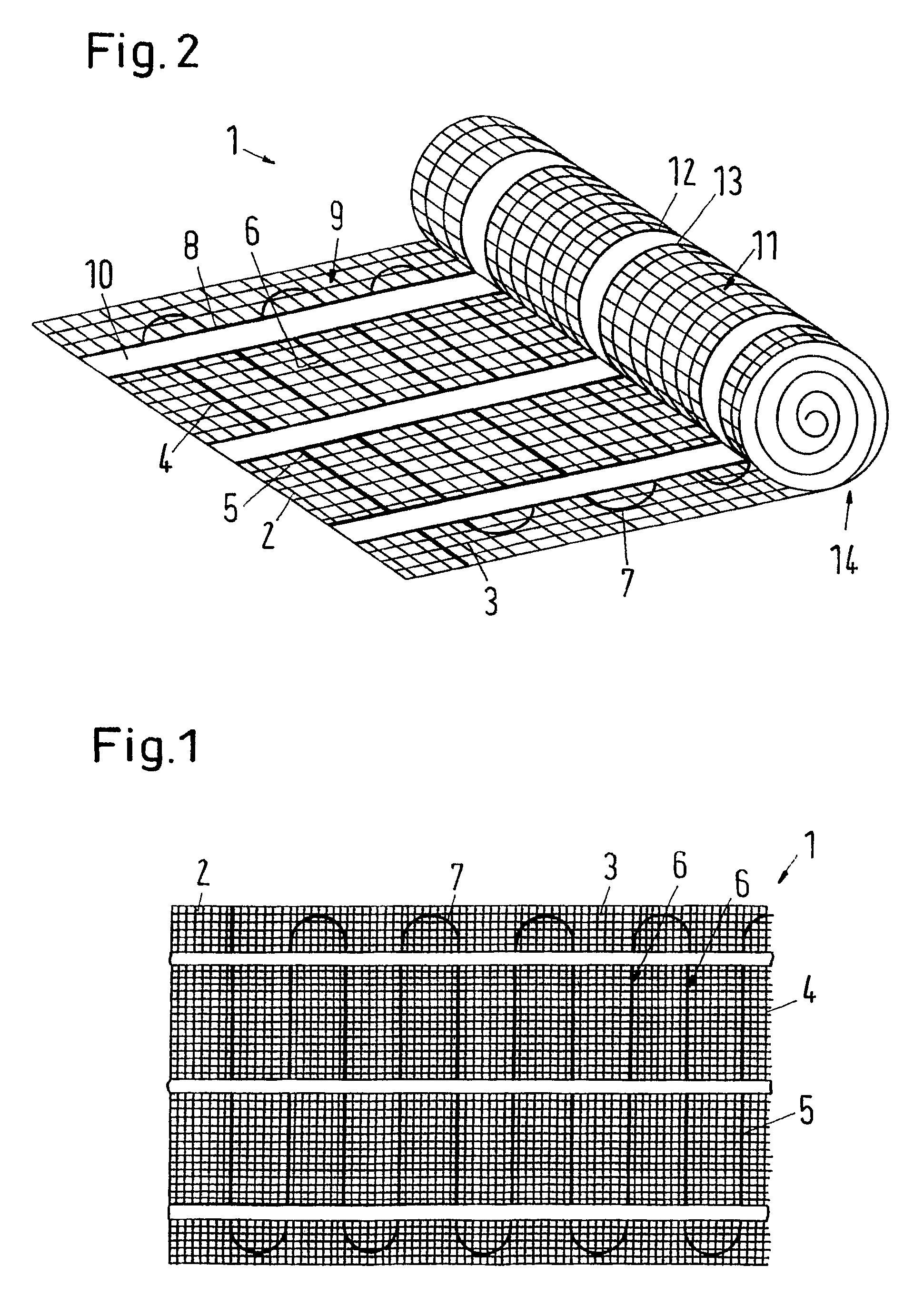

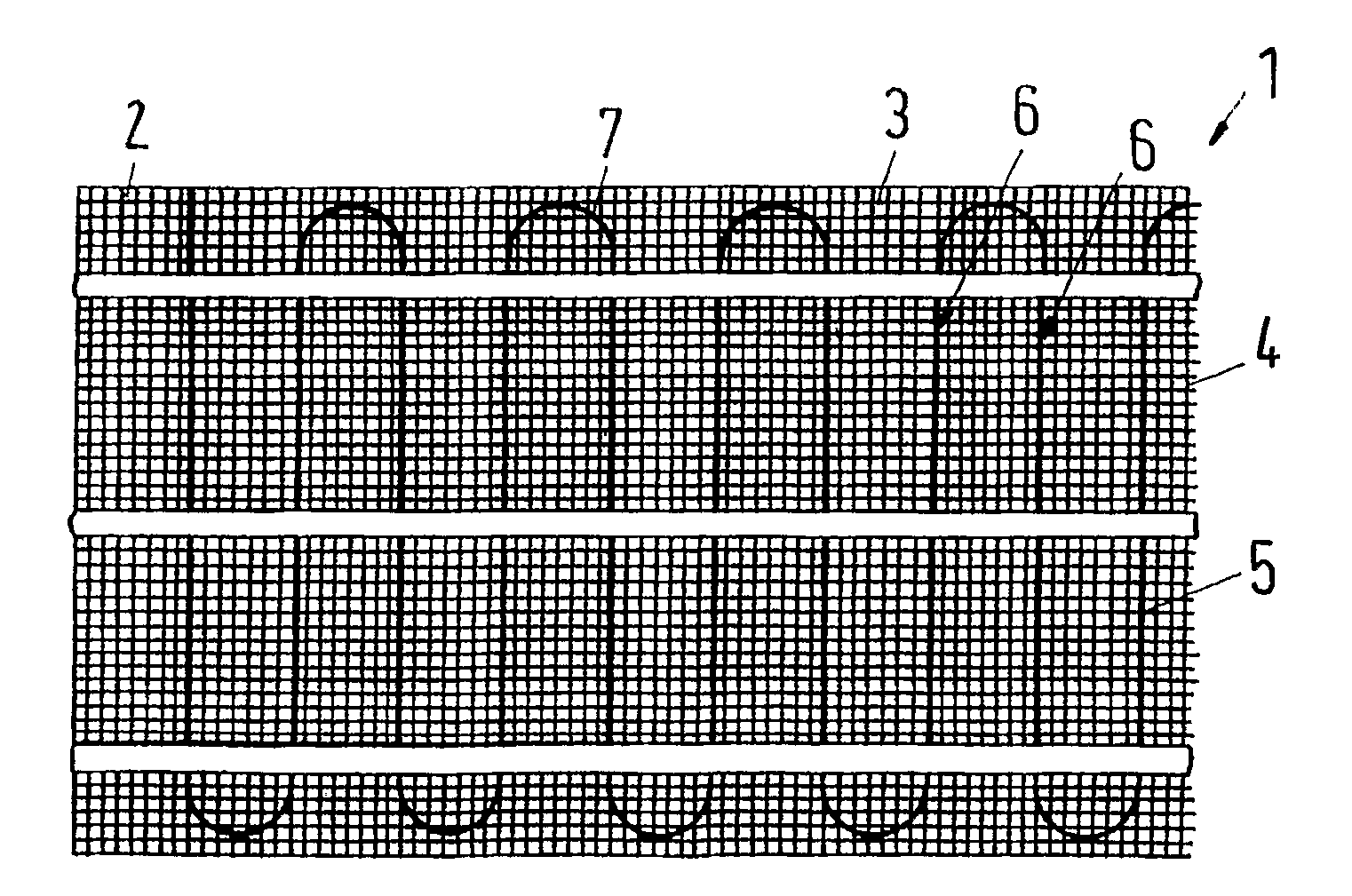

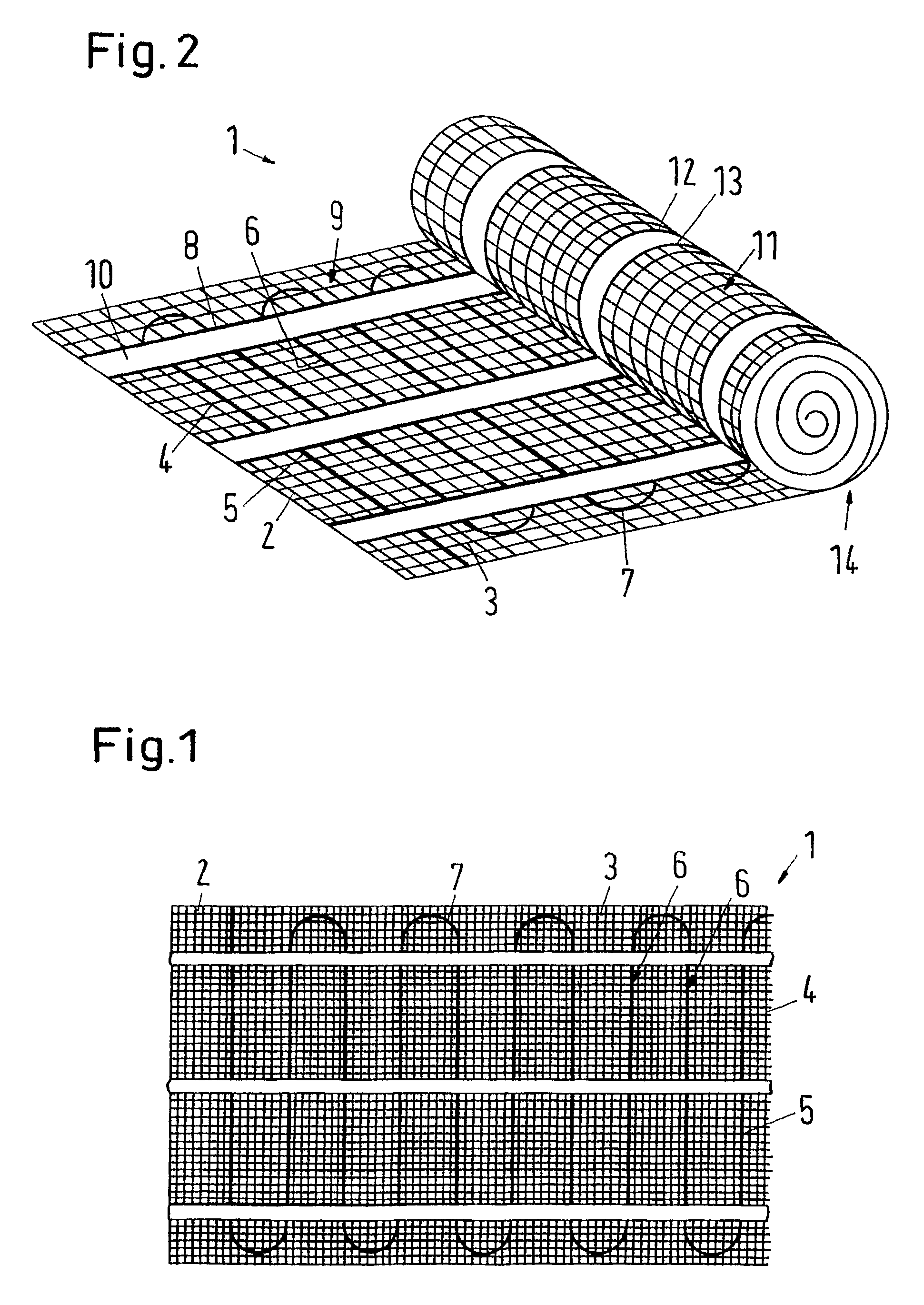

Heating or cooling mat

ActiveUS8816251B2Easy to disengagePrecise heatingLighting and heating apparatusElectric heating systemAdhesiveCooling Units

The invention concerns a heating or cooling mat (1) with a carrying sheet (2) having a top side (9) and a bottom side (11), and at least one heating and cooling unit (5) located on the carrying sheet (2), an adhesive being located on the bottom side (11) of the carrying sheet (2). It is endeavored to improve the handling properties of the heating or cooling mat. For this purpose, the adhesive is located on a double-sided adhesive tape (12), which is fixed on the bottom side (11) of the carrying sheet (2), the adhesive on the bottom side of the adhesive tape (12) being covered by the top side of the carrying sheet (2) and the adhesive tape (12) bonding with the top side of the carrying sheet (2) in the rolled up state of the heating or cooling mat (1).

Owner:DANFOSS AS

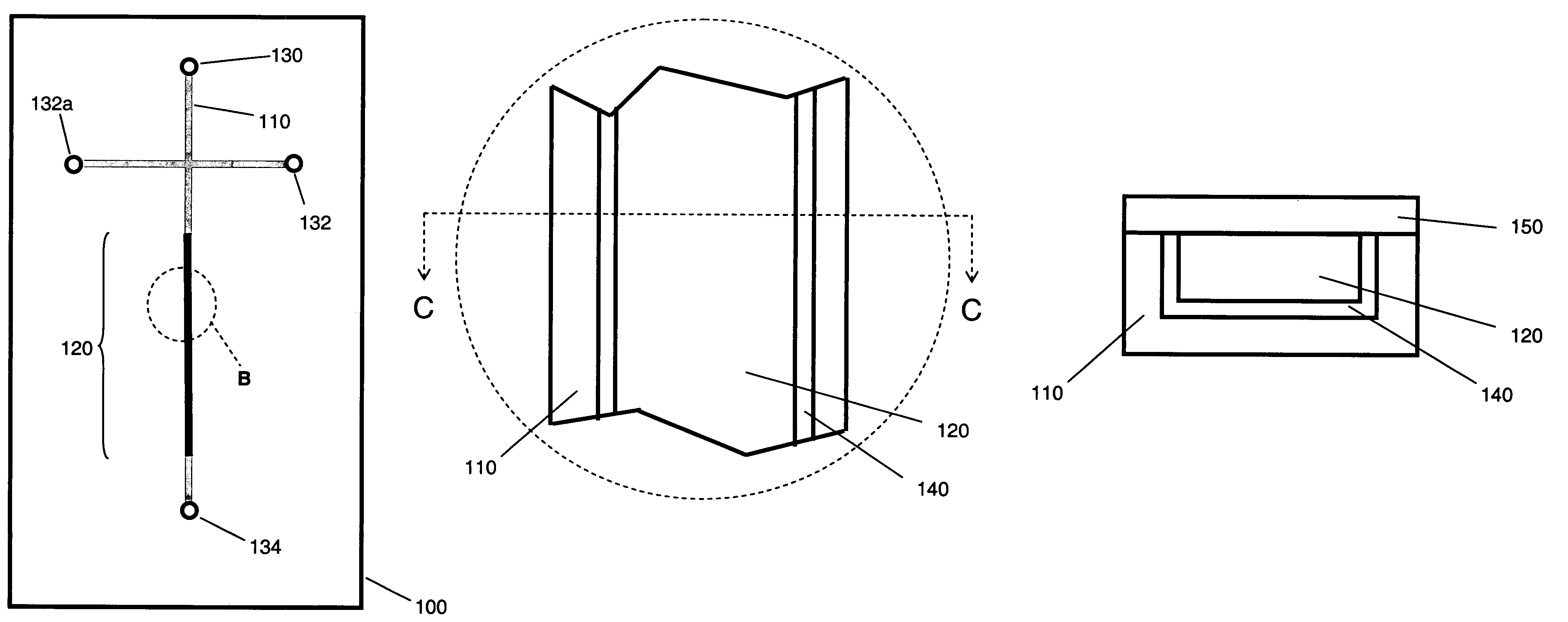

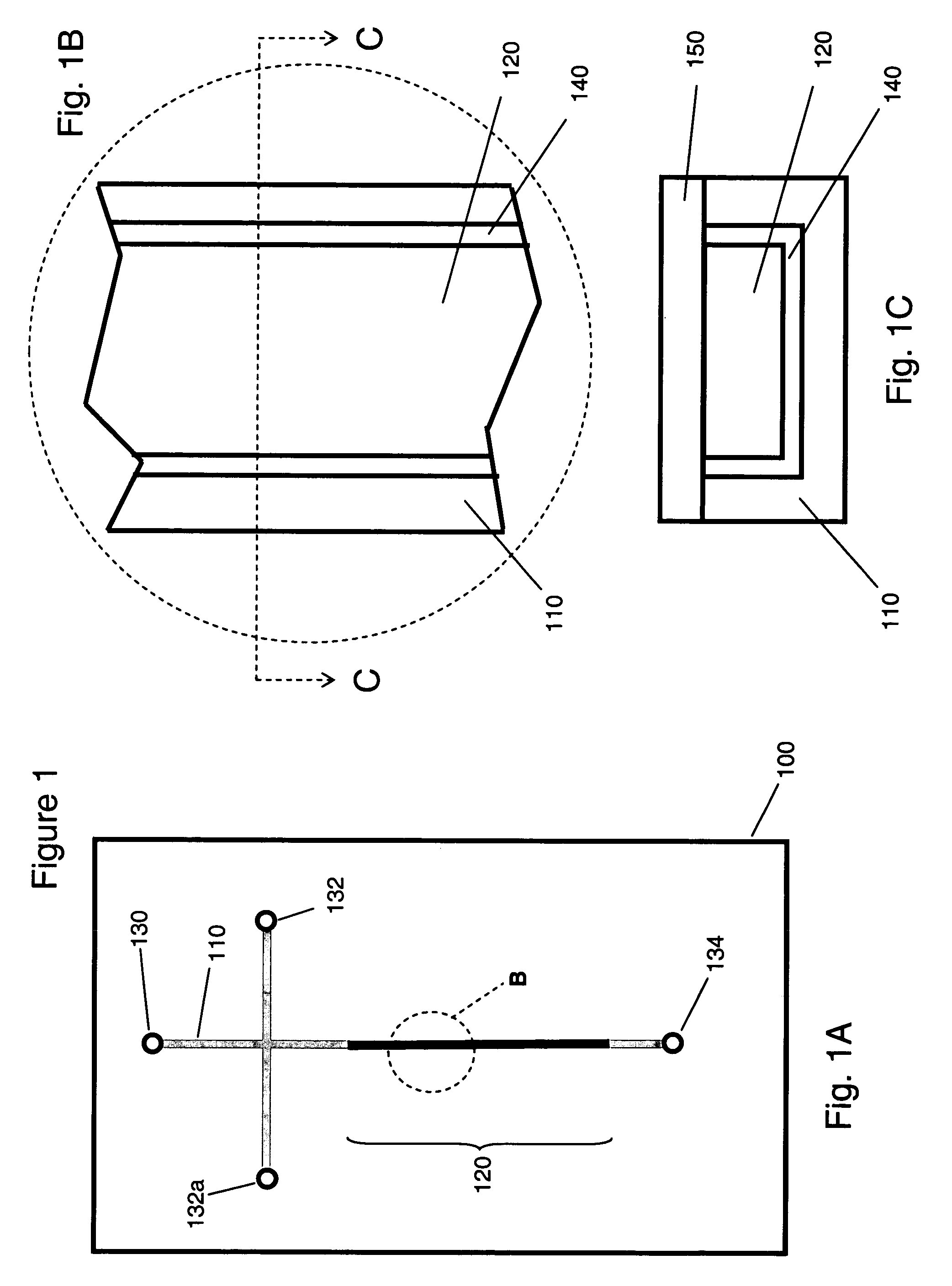

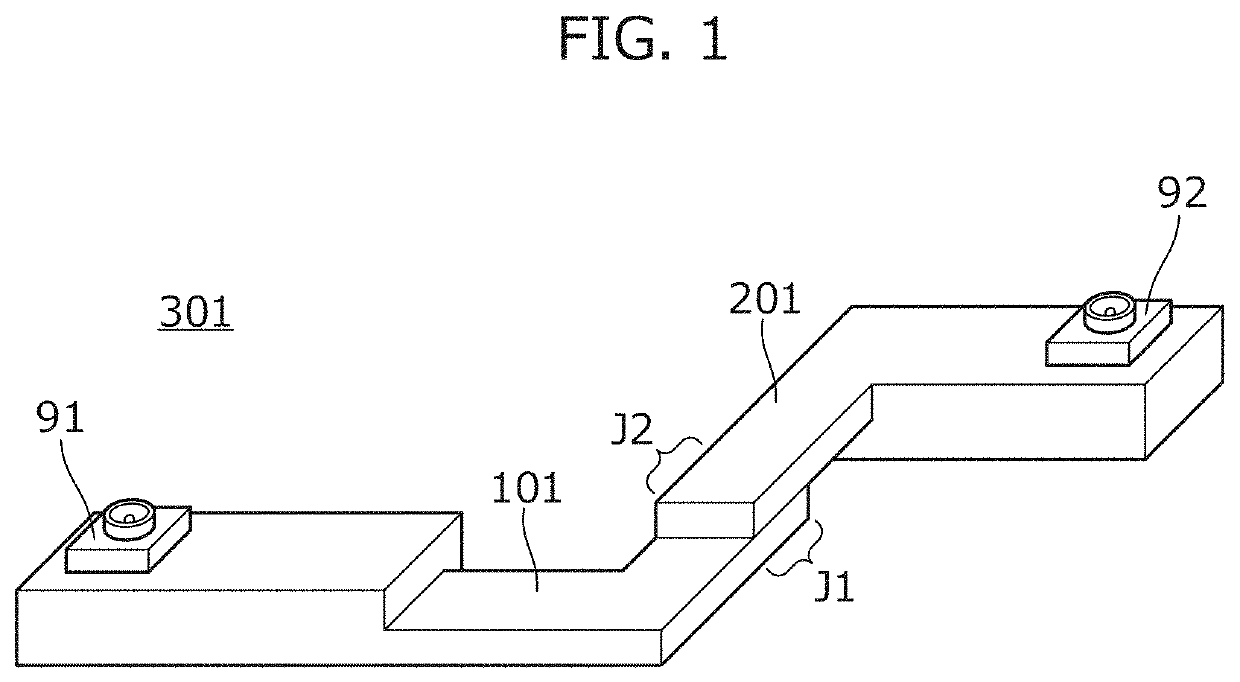

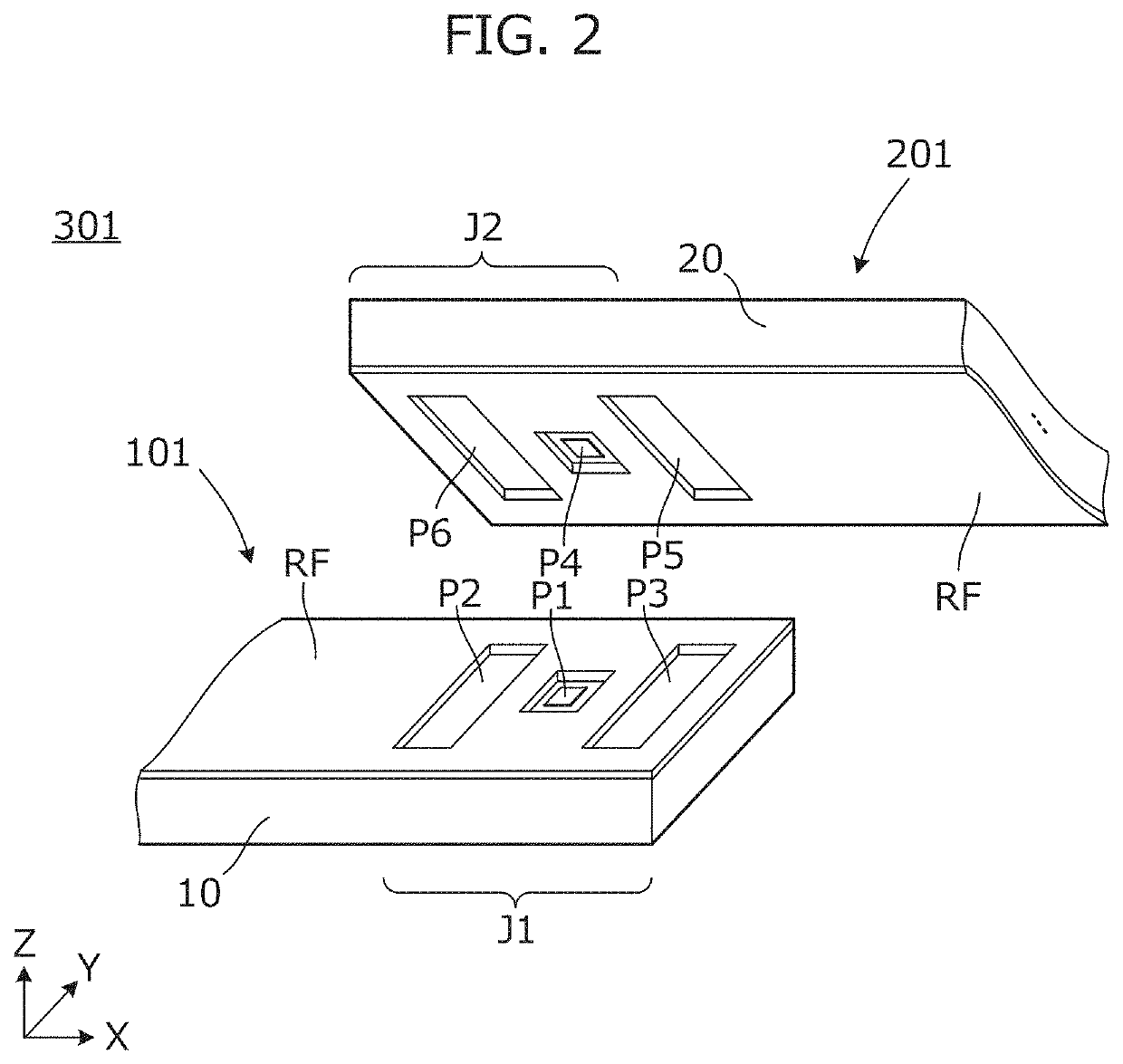

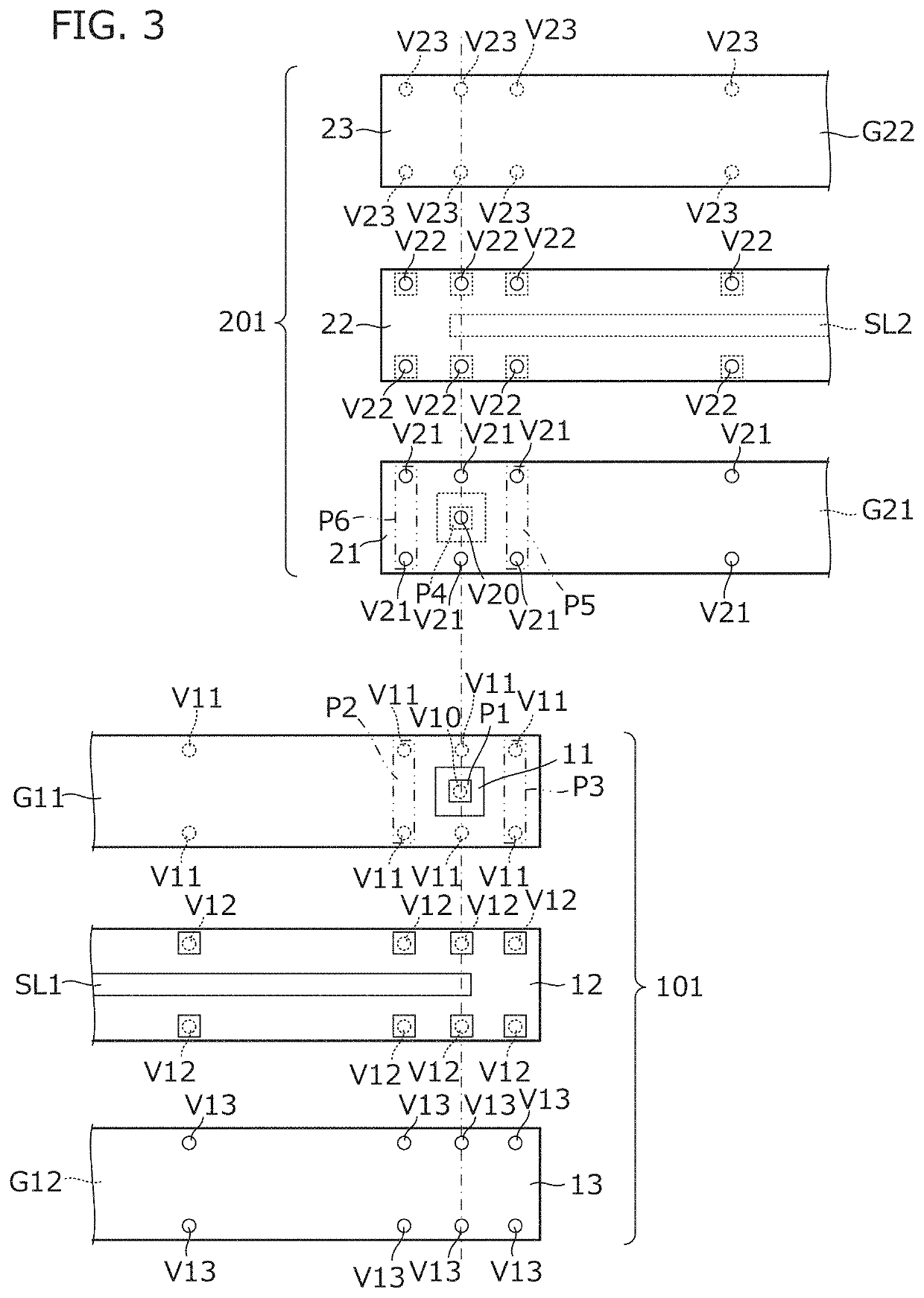

Transmission line device

ActiveUS20200194859A1Poor bondingPrinted circuit assemblingPrinted circuit aspectsElectrical conductorElectrical connection

A transmission line device includes first and second transmission lines. The first transmission line includes a first electrode pad that is electrically connected to a first signal conductor pattern, and a second electrode pad and a third electrode pad that are portions of a first ground conductor pattern. The second transmission line includes a fourth electrode pad that is electrically connected to a second signal conductor pattern, and a fifth electrode pad and a sixth electrode pad that are portions of a second ground conductor pattern. The first electrode pad is between the second electrode pad and the third electrode pad, and the fourth electrode pad is between the fifth electrode pad and the sixth electrode pad. The second electrode pad and the third electrode pad are larger than the first electrode pad, and the fifth electrode pad and the sixth electrode pad are larger than the fourth electrode pad.

Owner:MURATA MFG CO LTD

Thin film transistor array panel of active liquid crystal display and fabrication method thereof

InactiveUS7521298B2Easy to superviseLower ratioSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayEtching

Owner:WINTEK CORP

Heating and cooling mat

ActiveUS20090050616A1Easy to disengagePrecise heatingLighting and heating apparatusElectric heating systemAdhesiveEngineering

The invention concerns a heating and cooling mat (1) with a carrying sheet (2) having a top side (9) and a bottom side (11), and at least one heating and cooling unit (5) located on the carrying sheet (2), an adhesive being located on the bottom side (11) of the carrying sheet (2). It is endeavoured to improve the handling properties of the heating and cooling mat. For this purpose, the adhesive is located on a double-sided adhesive tape (12), which is fixed on the bottom side (11) of the carrying sheet (2), the adhesive on the bottom side of the adhesive tape (12) being covered by the top side of the carrying sheet (2) and the adhesive tape (12) bonding with the top side of the carrying sheet (2) in the rolled up state of the heating and cooling mat (1).

Owner:DANFOSS AS

Methods for producing coated film

ActiveUS8007873B2Quality improvementLow production costDielectric heatingRadiation applicationsWater basedMicrowave

The present invention discloses a method for producing coated film, comprising the following procedures of: coating water-based macromolecular emulsion on the surface of a film substrate, drying the film substrate coated with emulsion with microwave, and then curing the dried film to make the coating crystallize homogeneously. The coated films produced with that method are tolerant to friction and are featured with strong resistance to scraping, high tensility, high contractility, excellent antistatic property, low surface friction factor, perfect glossiness, high oxygen and water obstruction property, and low production cost, and are especially suitable for producing high-performance thermal contracting coated films. The contracting films produced with the method may be used as esthetic and abrasion-resistant wrapping material and may help to extend quality guarantee period of articles.

Owner:HAINAN SHINER IND

Method for preparing metal plating on magnesium alloy surface

InactiveCN107779867APoor bondingImprove bindingLiquid/solution decomposition chemical coatingSuperimposed coating processElectroless nickelCompound (substance)

A method for preparing a metal coating on the surface of a magnesium alloy, the method comprising the following steps: (1) performing pretreatment on the surface of the magnesium alloy; (2) performing pre-electroless nickel plating on the surface of the pre-treated magnesium alloy; The surface of the magnesium alloy after electroless nickel plating is thickened by electroless nickel plating or electroplated with other metals. The method of the present invention improves the bonding force between the pre-plating layer and the magnesium alloy substrate, and is tested by standard methods, and the bonding force between the pre-plating nickel layer and the substrate is good, reaching the national standard; further thickening the electroless nickel plating or electroplating on the pre-nickel layer For other metals, a metal decorative protective coating with strong bonding force and high corrosion resistance can be obtained.

Owner:范晓明

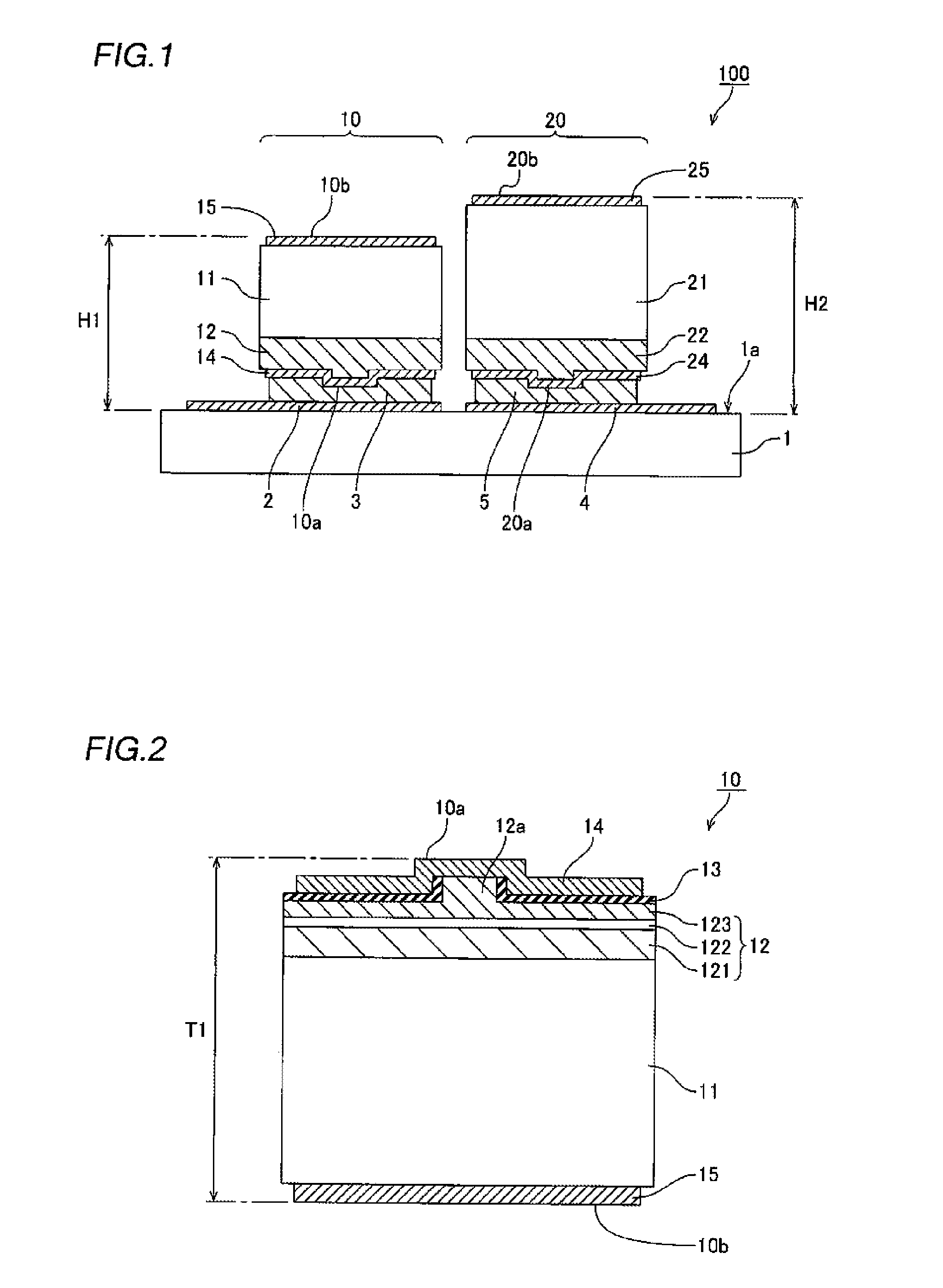

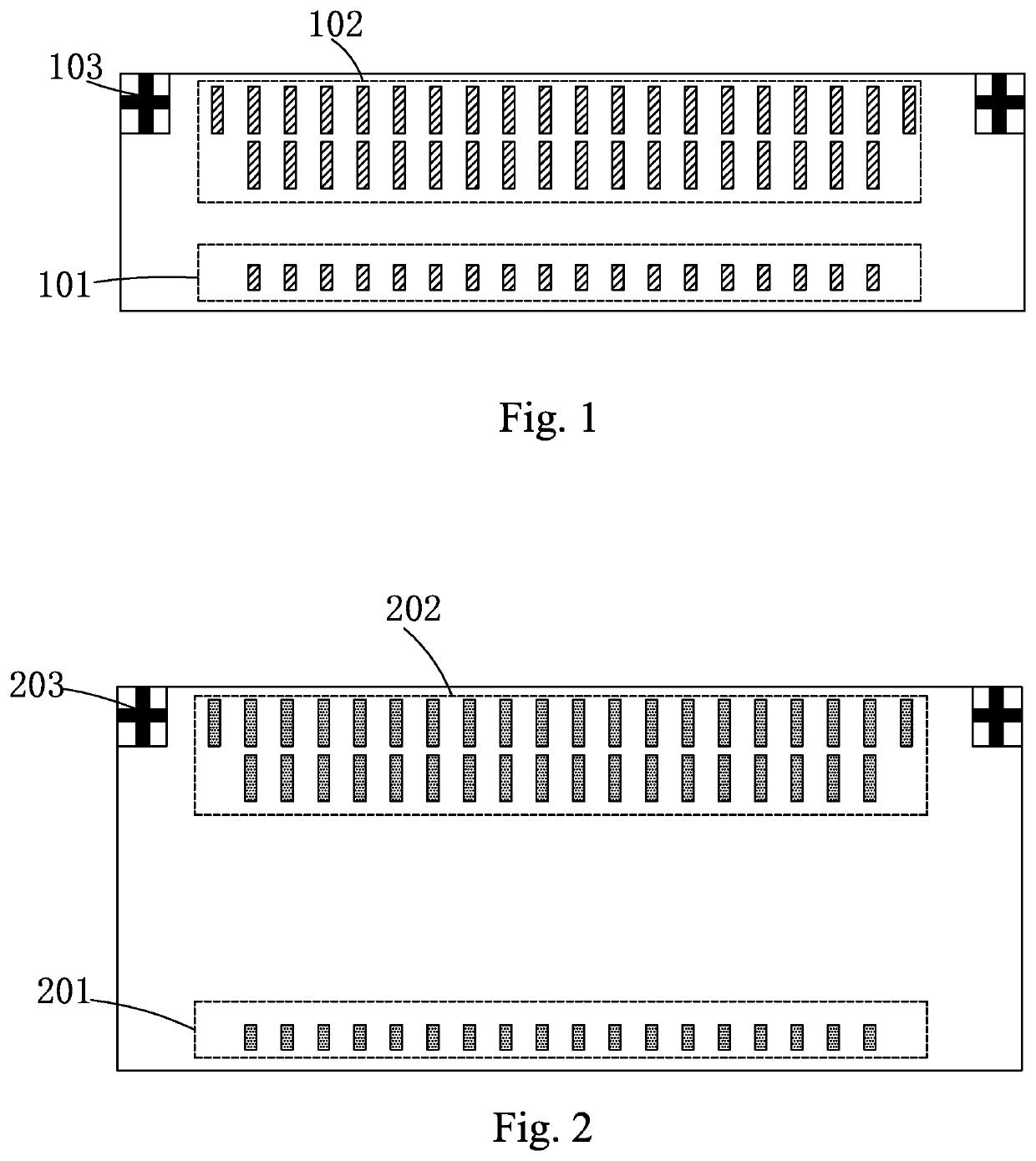

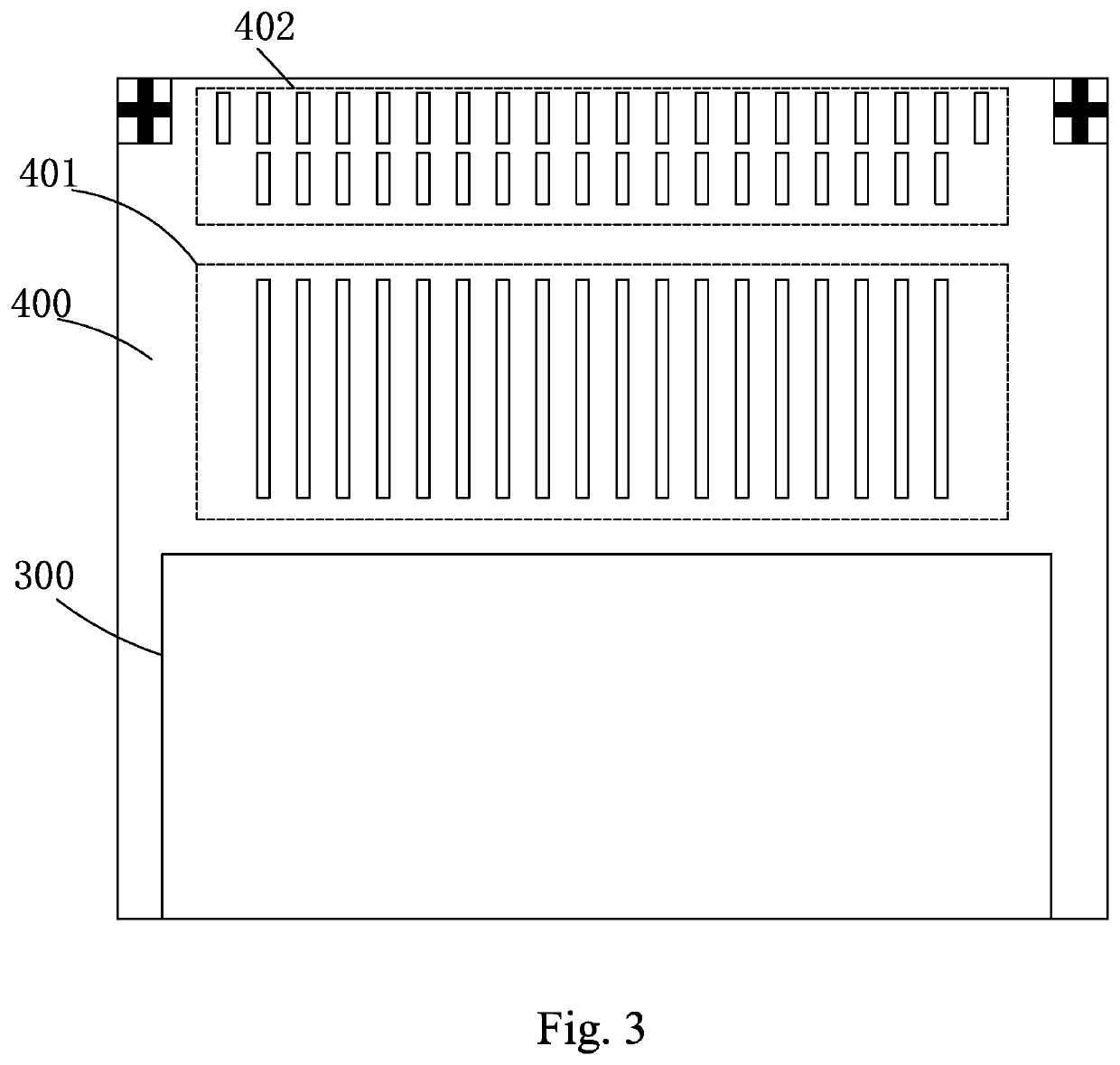

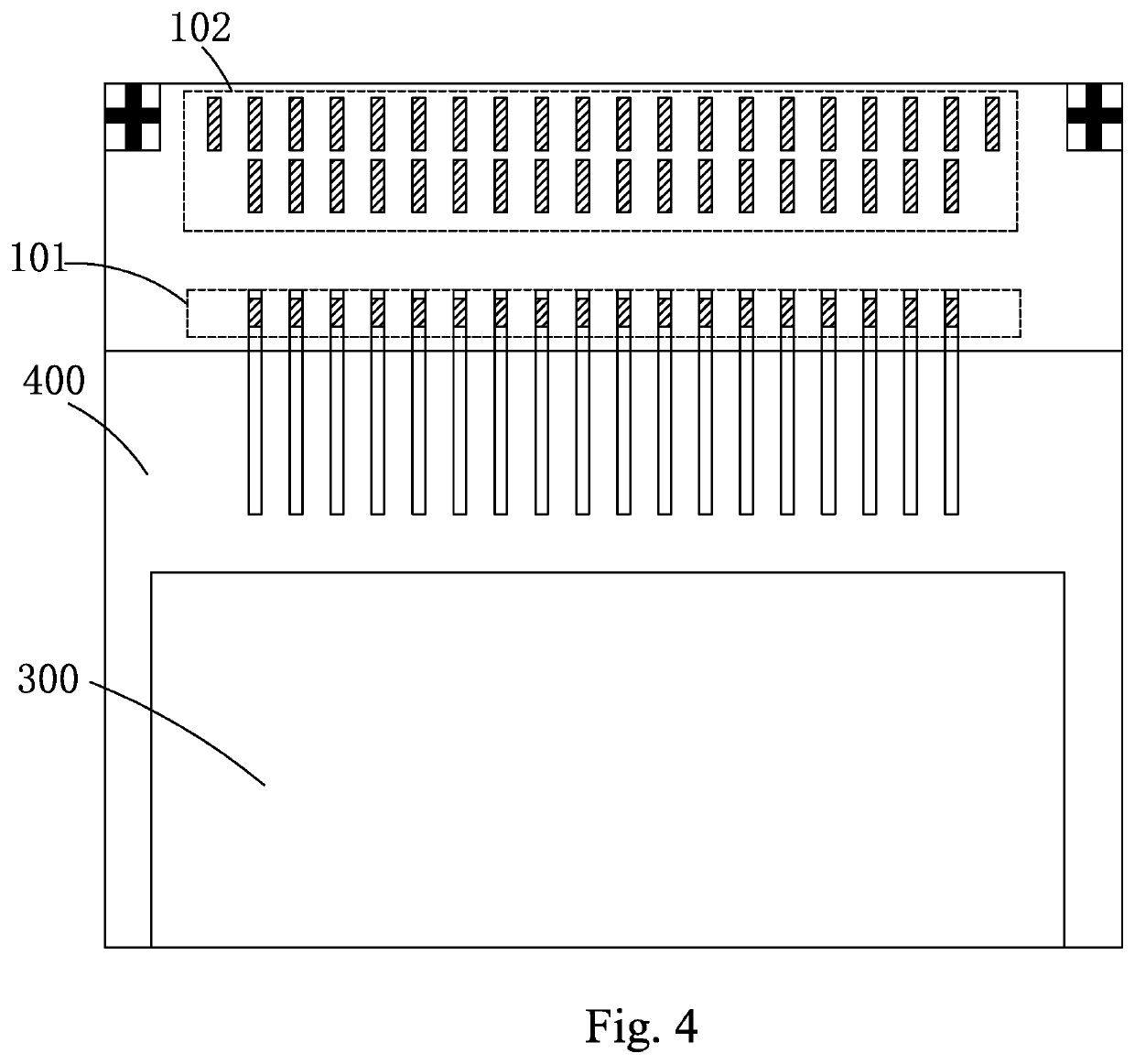

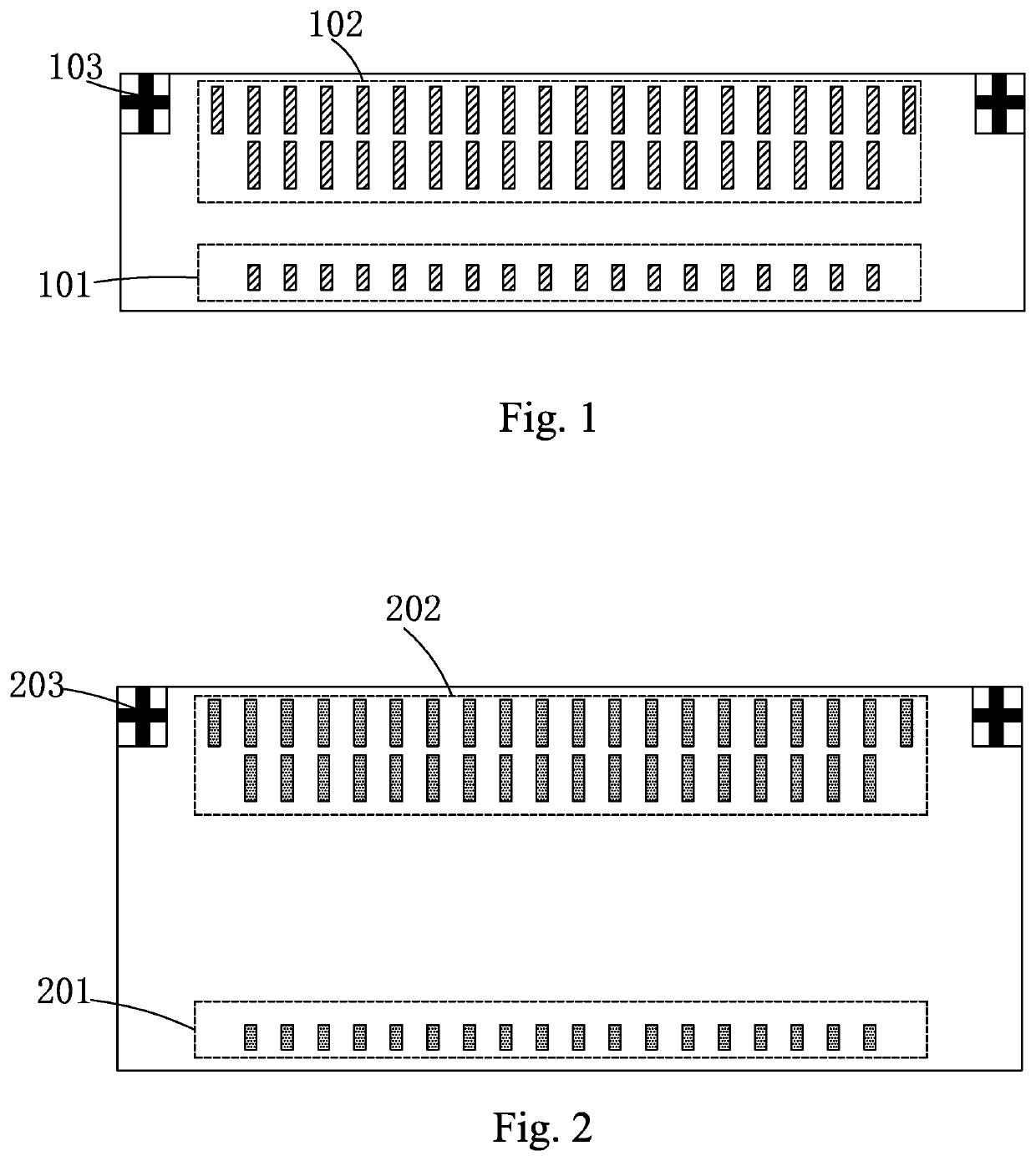

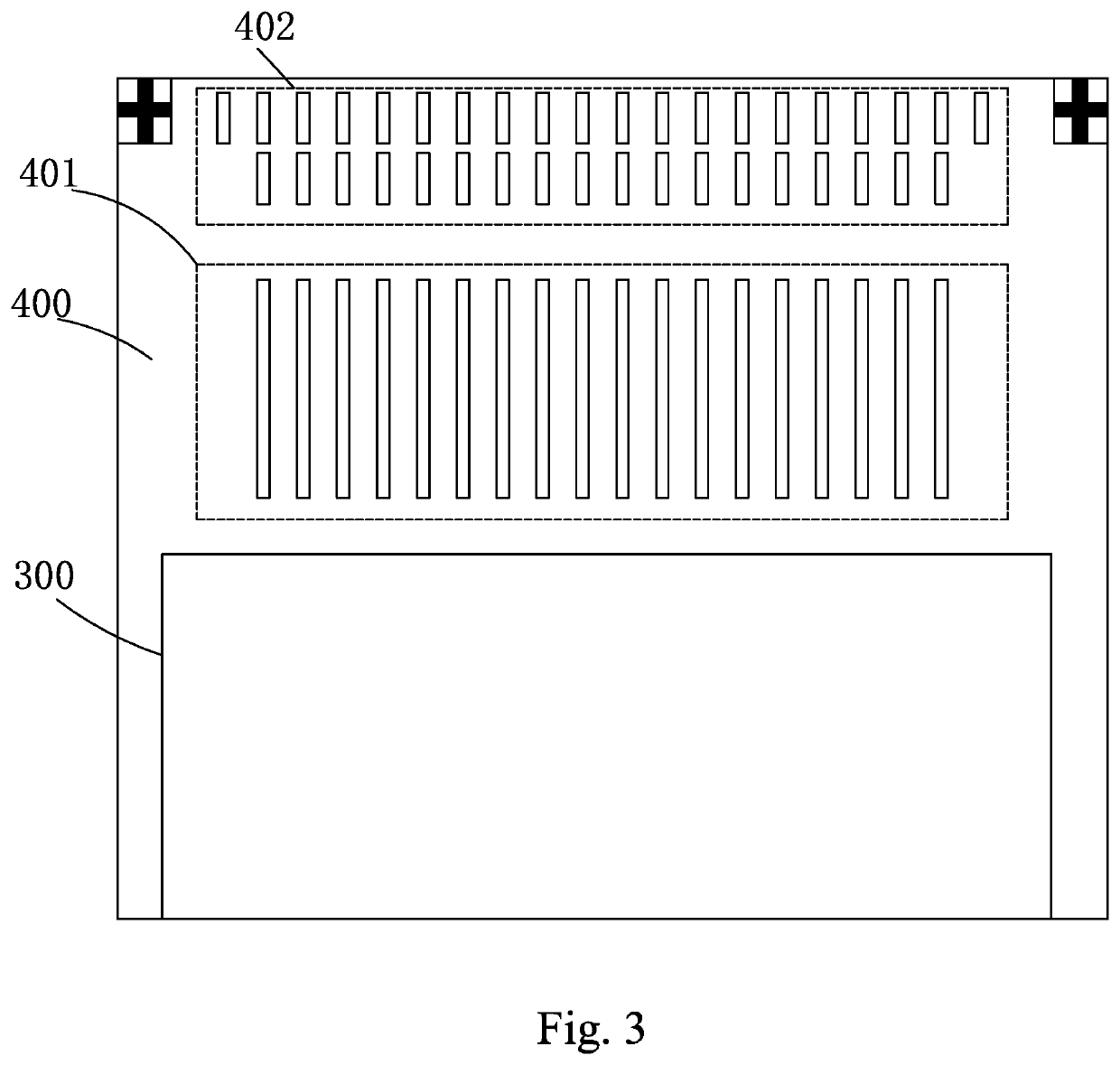

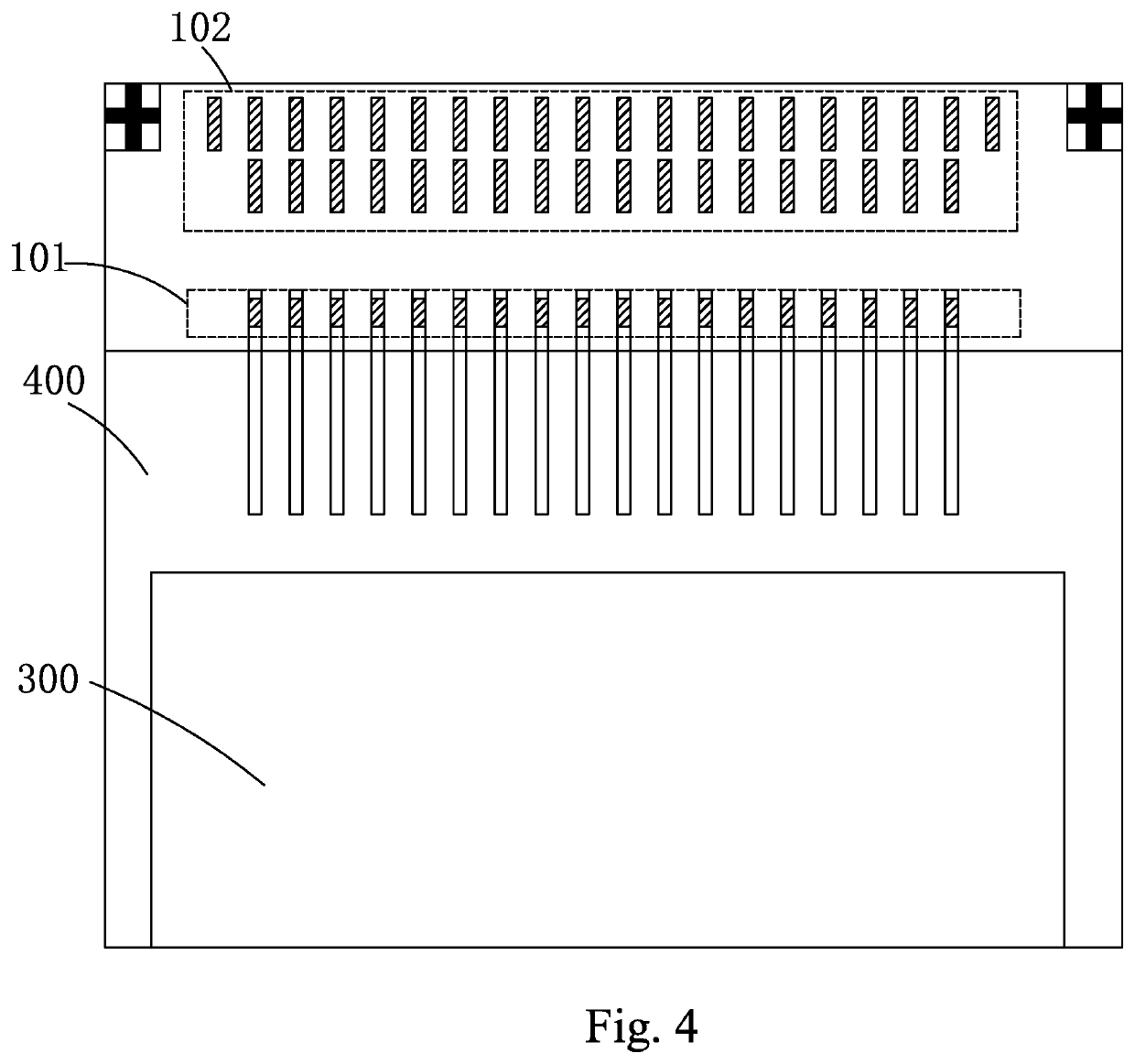

Array substrate and chip bonding method

ActiveUS20210091027A1Reducing poor chip bondingGuaranteed display qualitySemiconductor/solid-state device detailsSolid-state devicesDie bondingMechanical engineering

The invention provides an array substrate and chip bonding method, the array substrate comprising: an active area, and a bonding area located around the active area, wherein the bonding area is provided with an input terminal group, a first output terminal group and a second output terminal a group; the first output terminal group is located at a side of the input terminal group away from the active area, and the second output terminal group is located between the first output terminal group and the input terminal group; when bonding chips, the first output terminal group or the second output terminal group is selected to cooperate with the input terminal group for chip bonding according to the chip type. By simultaneously providing the first and second output terminal groups, the bonding of the second type chip increases the distance between the chip and the edge of the array substrate.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Organopolysiloxane composition for bonding to magnesium alloy

ActiveUS7396867B2Good self-adhesiveImprove adhesionNon-macromolecular adhesive additivesSpecial tyresOxygenHydrocarbon

An organopolysiloxane composition for bonding to magnesium alloys comprises (A) 100 parts by weight of an organopolysiloxane of the following general formula (1) and / or (2)wherein R may be the same or different and represents a substituted or unsubstituted monovalent hydrocarbon group having 1 to 10 carbon atoms, and n is an integer of at least 10, X represents an oxygen atom or an alkylene group having 2 to 5 carbon atoms, and m independently represents an integer of 0 or 1, (B) 0.1 to 50 parts by weight of an organosilicon compound having at least three hydrolyzable groups bonded to silicon atoms in one molecule and / or a partial hydrolyzate thereof, and (C) 0.1 to 15 parts by weight of an acidic silane coupling agent.

Owner:SHIN ETSU CHEM IND CO LTD

Optical fiber manufacturing apparatus and optical fiber manufacturing method

ActiveUS8701445B2Satisfactory sealing abilityImprove sealingGlass fibre drawing apparatusMechanical engineeringOptical fiber

An optical fiber manufacturing apparatus for manufacturing an optical fiber by drawing a optical fiber preform, including: a drawing furnace having therein a muffle tube into which the optical fiber preform is inserted and heating the optical fiber preform; and a first seal member which is disposed at an insert side of the drawing furnace so as to be coaxial with the drawing furnace and which seals the optical fiber preform inserted into an opening formed at the center thereof, wherein the first seal member includes a plurality of inner-circumference slits formed in the inner circumference thereof and a plurality of outer-circumference slits formed in the outer circumference thereof.

Owner:FUJIKURA LTD

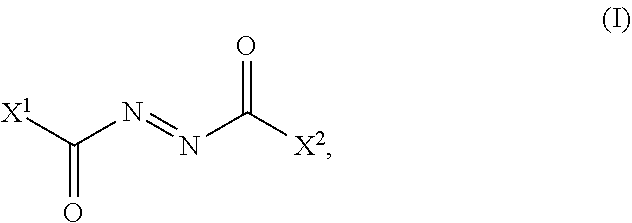

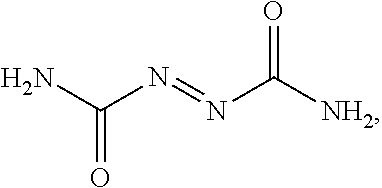

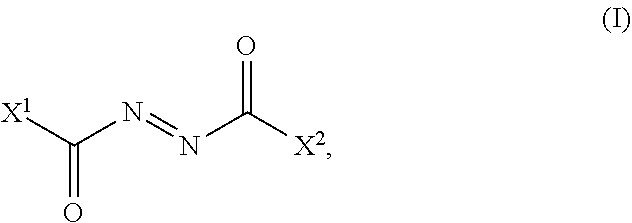

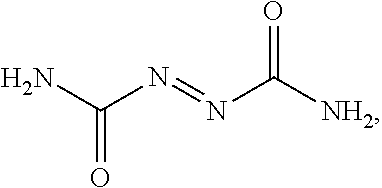

Gas generating compositions

ActiveUS20210047552A1Constant viscosityLow compressibilityDrilling compositionCeramicwareActive agentSurface-active agents

The present application provides a gas-generating aqueous fluid containing a gas-generating compound like an azo compound, and an organic amine like a primary, secondary or tertiary amine, a hydrazine, a hydrazide, or a semicarbazide. The aqueous fluid may also a viscosifler, and a foaming surfactant. The present application also provides a method of using the gas-generating composition to modulate density of a wellbore fluid for use in downhole applications. The method optionally includes adding an oxidizer to the wellbore fluid.

Owner:SAUDI ARABIAN OIL CO

Shaped nanoporous bodies

ActiveUS10773234B2Little and distortionIncrease rangeCarbon compoundsOther blood circulation devicesCellulosePolymer science

A range of carbon materials can be produced using lignin in combination with synthetic phenolic resins or naturally occurring lingo-cellulosic materials. The lignin, which is essentially a naturally occurring phenolic resin, has a carbon yield on pyrolysis similar to that of the synthetic resins, which aids processing. The lignin can be used as a binder phase for synthetic resin or lignocellulosic materials allowing the production of monolithic carbons from a wide range of precursors, as the primary structural material where the thermal processing is modified by the addition of small quantities of synthetic resin materials or as structure modified in the production of meso / macro porous carbons in either bead, granular or monolithic form. A carbonised monolith is provided comprising mesoporous and / or macroporous carbon particles dispersed in a matrix of microporous carbon particles with voids between the particles defining paths for fluid to flow into and through the structure. The monolith may take the form of a shaped body having walls defining a multiplicity of internal transport channels for fluid flow, the transport channels being directed along the extrusion direction. The monolith may be made by carbonising a shaped phenolic body based on phenolic resin precursors. In a method for producing such a carbonisable shaped resin body solid particles of a first phenolic resin are provided which is partially cured so that the particles are sinterable but do not melt on carbonisation. The particles of the first phenolic resin are mixed with particles of a second phenolic resin that has a greater degree of cure than said first phenolic resin and has a mesoporous and / or macroporous microstructure that is preserved on carbonisation. The resulting mixture is formed into a dough e.g. by mixing the resin particles with methyl cellulose, PEO and water, after which the dough is extruded to form a shaped product and stabilising in its shape by sintering.

Owner:NEOTERYX

Gas generating compositions

ActiveUS11203708B2Constant viscosityLow compressibilityDrilling compositionCeramicwareActive agentSurface-active agents

The present application provides a gas-generating aqueous fluid containing a gas-generating compound like an azo compound, and an organic amine like a primary, secondary or tertiary amine, a hydrazine, a hydrazide, or a semicarbazide. The aqueous fluid may also a viscosifier, and a foaming surfactant. The present application also provides a method of using the gas-generating composition to modulate density of a wellbore fluid for use in downhole applications. The method optionally includes adding an oxidizer to the wellbore fluid.

Owner:SAUDI ARABIAN OIL CO

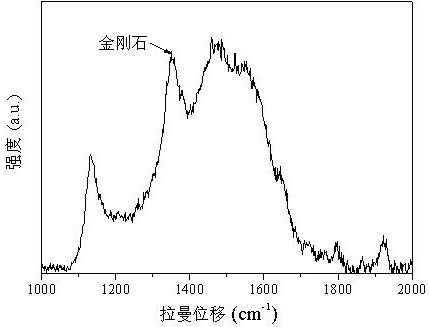

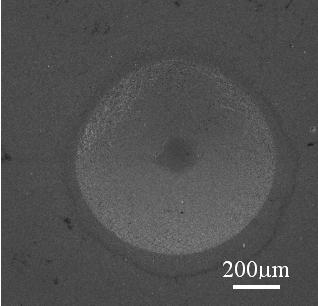

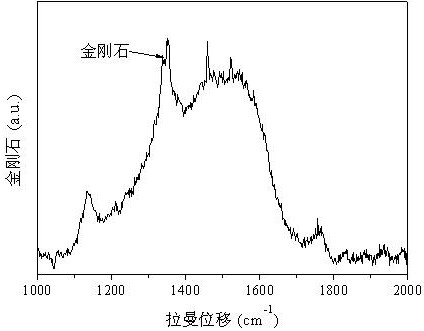

A method for preparing diamond film on stainless steel surface with Cr/Craln as transition layer

ActiveCN110629194BStrong membrane bindingNo sheddingVacuum evaporation coatingSputtering coatingMetallurgySS - Stainless steel

The invention discloses a method for preparing a diamond film on the surface of stainless steel with Cr / CrAlN as a transition layer, which is characterized in that it comprises the following steps: S1: pretreatment of stainless steel samples: sanding the stainless steel samples with acetone and absolute ethanol Ultrasonic treatment, drying and standby; S2: Deposit Cr / CrAlN transition layer on the surface of stainless steel: put the stainless steel sample in the S1 step into the sample stage of the magnetron sputtering equipment, install the Cr and Al targets on the target holder, and place the Cr / CrAlN transition layer on the stainless steel Deposit a Cr film and a CrAlN film on the surface of the substrate to obtain a stainless steel sample containing a Cr / CrAlN transition layer; S3: Prepare a diamond film on the stainless steel surface: perform ultrasonic seeding on the stainless steel sample containing a Cr / CrAlN transition layer in step S2, and use a hot wire HFCVD is used to deposit diamond films to realize the preparation of diamond films on the surface of stainless steel containing Cr / CrAlN as a transition layer. Adopting the technology of the invention, the binding force between the diamond film and the stainless steel is high, and the film does not fall off under the action of a load of 150 kg on a Rockwell hardness tester.

Owner:ZHEJIANG UNIV OF TECH

Array substrate and chip bonding method

ActiveUS11101230B2Poor bondingGuaranteed display qualitySemiconductor/solid-state device detailsSolid-state devicesDie bondingMechanical engineering

The invention provides an array substrate and chip bonding method, the array substrate comprising: an active area, and a bonding area located around the active area, wherein the bonding area is provided with an input terminal group, a first output terminal group and a second output terminal a group; the first output terminal group is located at a side of the input terminal group away from the active area, and the second output terminal group is located between the first output terminal group and the input terminal group; when bonding chips, the first output terminal group or the second output terminal group is selected to cooperate with the input terminal group for chip bonding according to the chip type. By simultaneously providing the first and second output terminal groups, the bonding of the second type chip increases the distance between the chip and the edge of the array substrate.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

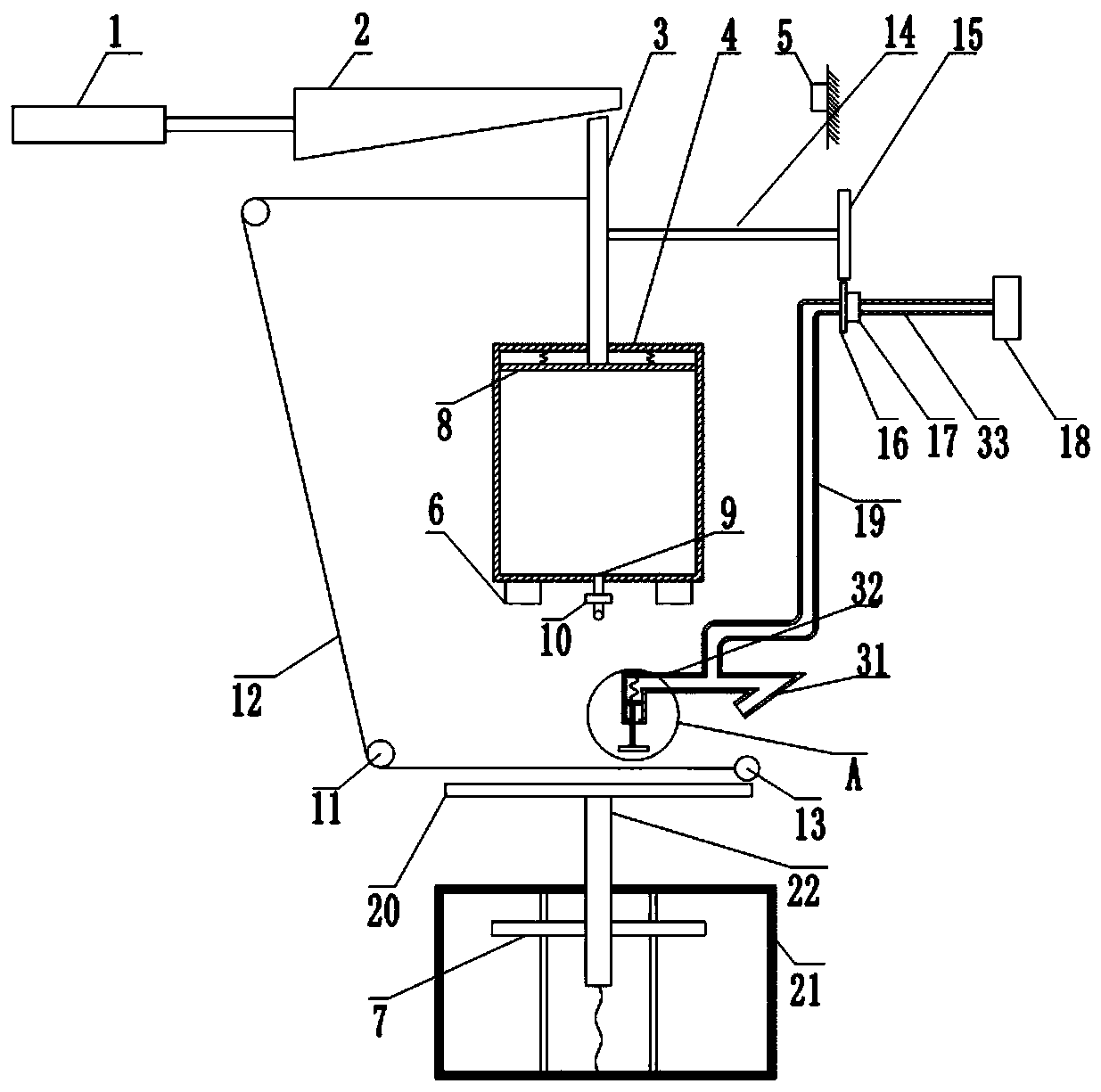

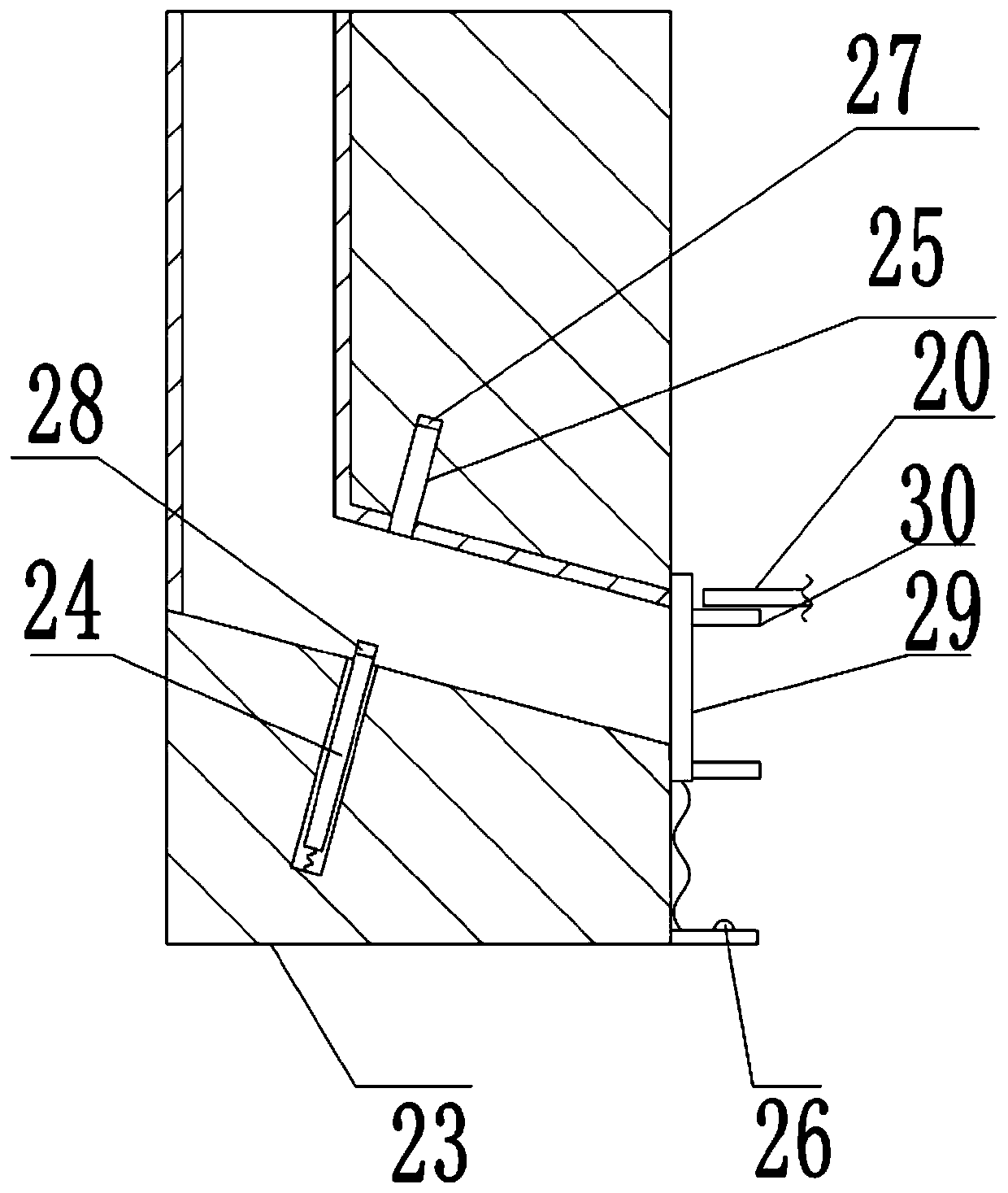

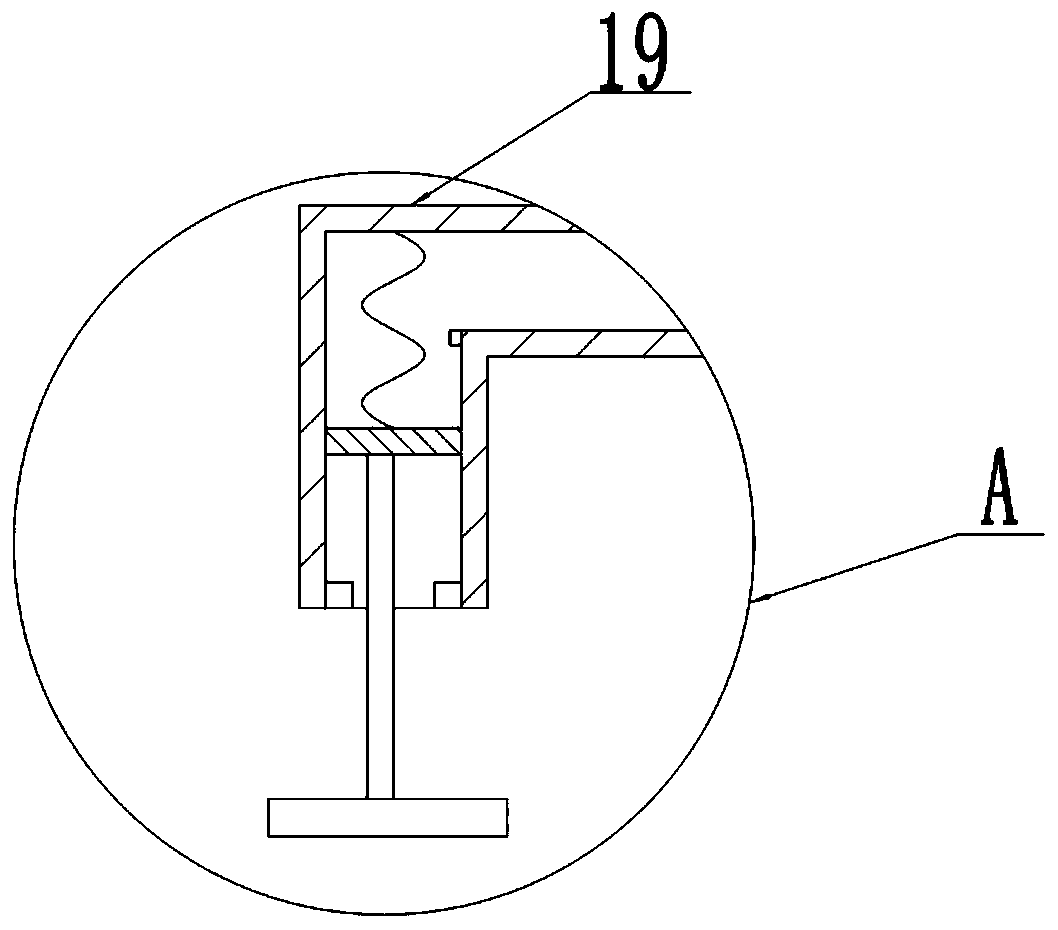

Training shoe gluing device

The invention relates to the field of shoe part bonding, and discloses a training shoe gluing device. The device comprises a rack and an air cylinder fixed to the rack, a piston rod of the air cylinder is coaxially connected with a wedge-shaped block which is in horizontal sliding connection with the rack, the rack is fixedly provided with a glue box and a workbench located below the glue box, andthe glue box is located on the lower side of the wedge-shaped block; a first piston plate is vertically and slidably connected with the interior of the glue box, and a wedge-shaped rod which is vertically and slidably connected with the rack is arranged between the first piston plate and the wedge-shaped block; the wedge-shaped rod is in sliding fit with the glue box, and an elastic piece is arranged between the upper surface of the first piston plate and the top wall of the inner side of the glue box; a glue outlet is formed in the bottom of the glue box, and a pressure valve is arranged atthe glue outlet; the rack is rotationally connected with a fixed pulley set, and the fixed pulley set comprises a first fixed pulley, a second fixed pulley and a pull rope; the rack is transversely and slidably connected with a roller between the glue box and the workbench, and the two ends of the pull rope are fixedly connected with the wedge-shaped rod and the roller respectively. According to the scheme, the device is used for gluing training shoes, and waste of glue can be reduced.

Owner:CHONGQING HUIMEI IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com