Training shoe gluing device

A gluing device and workbench technology, applied in footwear, gluing shoe parts, shoe-making machinery, etc., can solve problems such as poor bonding effect and uneven glue application, so as to avoid contact and stabilize the amount of glue output , the effect of reducing glue waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

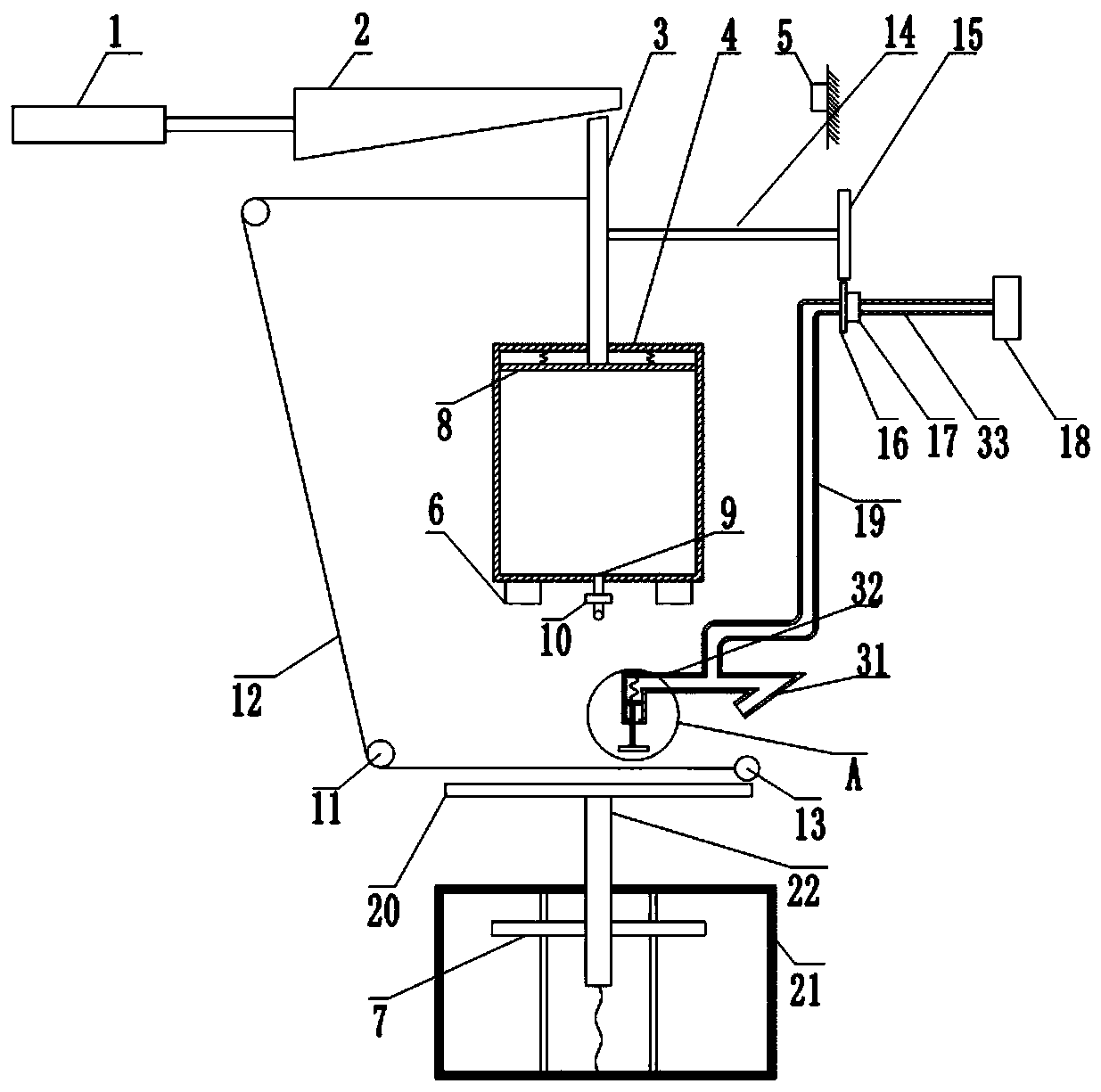

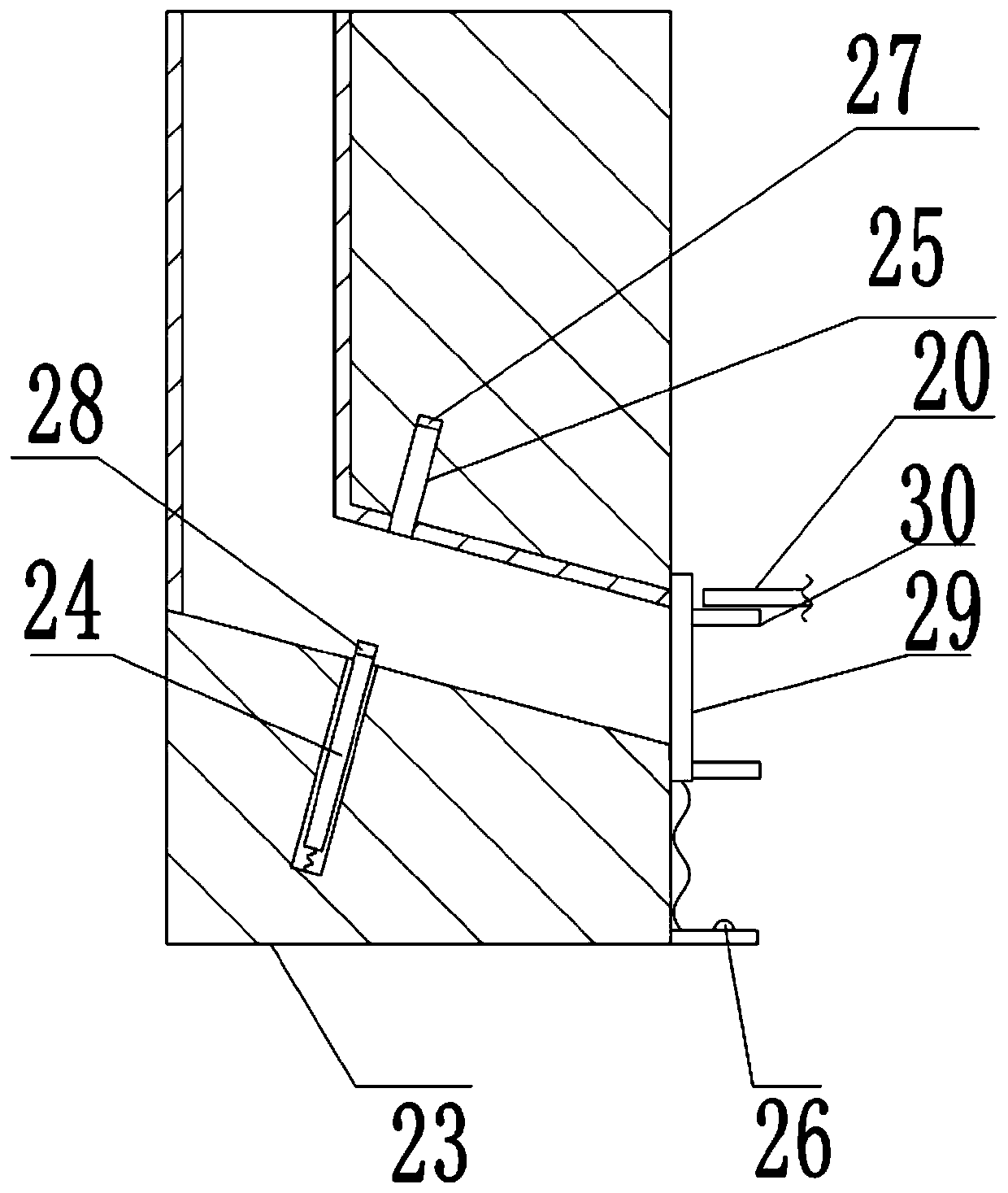

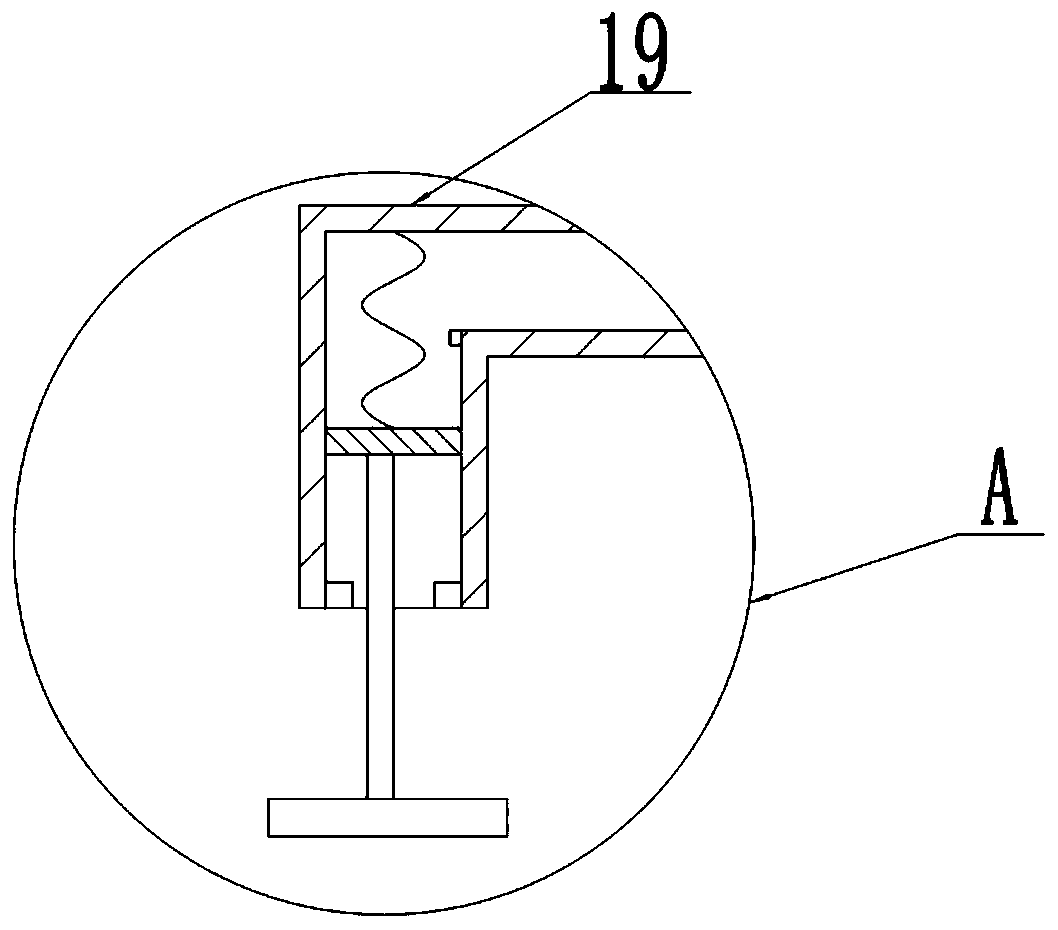

[0025] A kind of training shoes gluing device, such as figure 1 As shown, including a frame, the frame is fixed with a cylinder 1, a glue tank 4, a workbench 20 and a workbox 21 in order from top to bottom, and the upper surface of the workbench 20 is provided with a clamping groove capable of fixing the sole, and the size of the clamping groove is The same size as the sole, when the sole is placed in the groove, the bottom surface of the sole is flush with the upper surface of the workbench 20, the right side of the cylinder 1 is provided with a wedge block 2 that is horizontally slidably connected with the frame, and the piston rod of the cylinder 1 is connected to the wedge block. 2 welding, the right side of the wedge block 2 is provided with the first button switch 5 fixed on the frame, the button switch in the present embodiment is a normally closed switch, the first piston plate 8 is vertically slidably connected in the glue tank 4, An elastic member is welded between t...

specific Embodiment approach

[0031] The shoes that need to be glued are fixed in the clip groove on the workbench 20, and the soles are upward. Initially, the circuit of the button switch is turned on, and the first electromagnet 6 is energized to generate a magnetic field, which attracts the first magnet block 7 . Start the cylinder 1, and the piston rod drives the wedge block 2 to move laterally to the right, thereby exerting a downward pressure on the wedge rod 3, driving the wedge rod 3 to move down, so that the first piston plate 8 slides downward in the glue tank 4, The space pressure of the glue tank 4 below the first piston plate 8 is increased, the glue is extruded from the glue outlet 9, and falls on the fixed sole of the workbench 20, and the pull cord 12 is pulled while the wedge-shaped rod 3 slides, and the Rope 12 pulls cylinder 13 horizontally to the left, allowing glue to spread evenly on the sole.

[0032] When the wedge-shaped block 2 continues to move laterally to the right under the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com