Heterobonding molding device

A heterogeneous and hoisting technology, applied in the direction of microstructure devices, processing microstructure devices, precision positioning equipment, etc., can solve the problems of large errors, low degree of automation, poor repeatability of manual operations, etc., and achieve stable and high glue output. The effect of precision and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with embodiment the present invention is described in further detail:

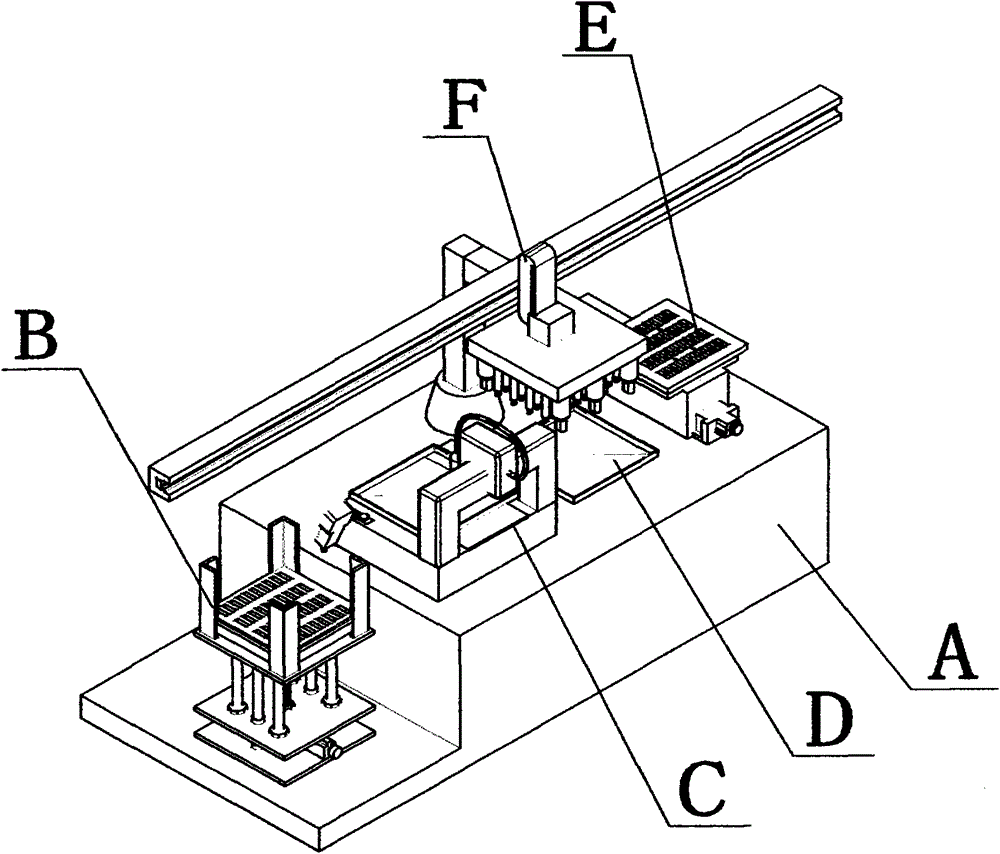

[0028] Heterobond forming devices such as figure 1 As shown, it includes workbench A, hoisting mechanism F, plate loading mechanism B, glue dispensing mechanism C, bonding mechanism D, and sheet loading mechanism E. The device is used to complete the bonding process of materials M and N of two different materials. The material M is made of PMMA with a size of 400mmX400mmX2mm. The material N is made of glass, and its size is 24mmX60mmX0.17mm. There are 40 through holes evenly distributed on the material M for placing the material N. The through holes are set in a stepped shape. The large end of the stepped hole is used to hold the material N, and the small end is used for other process requirements.

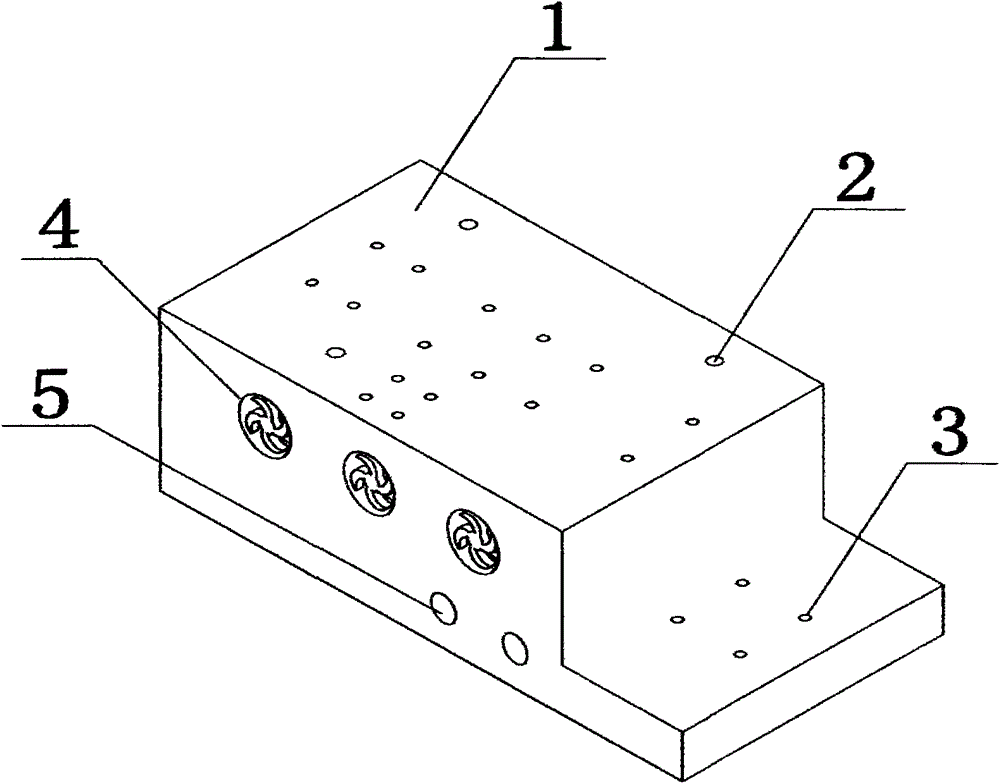

[0029] The workbench as figure 2 As shown, it is a rectangular cabinet 1 structure with steps, which is used as a load-bearing and accommodation facility for all precision mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com