Glue amount compensation control system

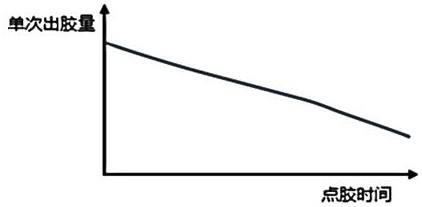

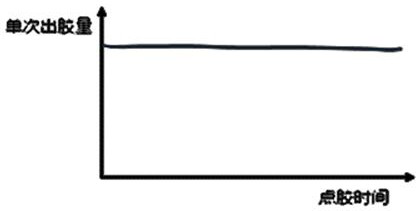

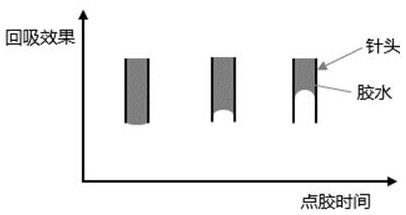

A technology of compensation control and glue quantity, which is applied to devices and coatings that apply liquid to the surface. It can solve the problems of air sucking back, affecting the dispensing quality, and becoming larger.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0077] Example 2: The dispensing equipment dispenses the product, the total dispensing time is 5S, and the dispensing times are 5 times. The compensation air pressure value corresponding to the voltage value is: 8V voltage value corresponds to 35 KPA compensation air pressure value, and 9V voltage value corresponds to 40 KPA Compensation air pressure value, 10V voltage value corresponds to 60 KPA compensation air pressure value, 12V voltage value corresponds to 90 KPA compensation air pressure value, 15V voltage value corresponds to 130 KPA compensation air pressure value; Perform pressure compensation (both positive pressure compensation and negative pressure compensation at the same time) through the switching of the positive pressure air circuit and negative pressure air circuit of the high-speed solenoid valve, the dispensing equipment can dispens the product, and through the positive pressure compensation of the dispensing equipment and negative pressure compensation, so a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com