Micro-nano polycrystalline diamond composite material and preparation method thereof

A polycrystalline diamond and micro-diamond technology, applied in the field of composite materials, can solve the problems of high equipment requirements, difficult application, high cost, etc., and achieve the effects of pressure loss promotion, performance improvement, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

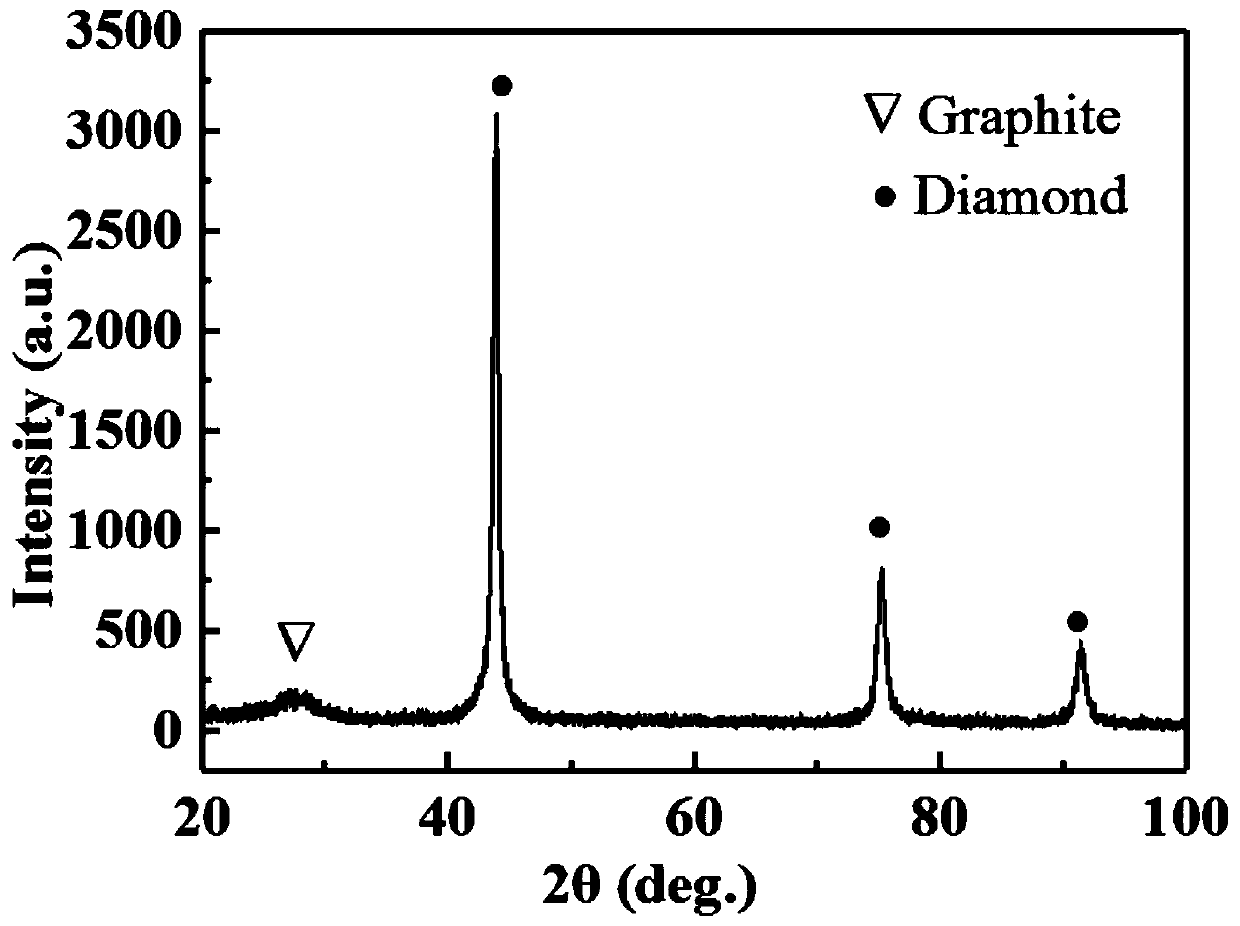

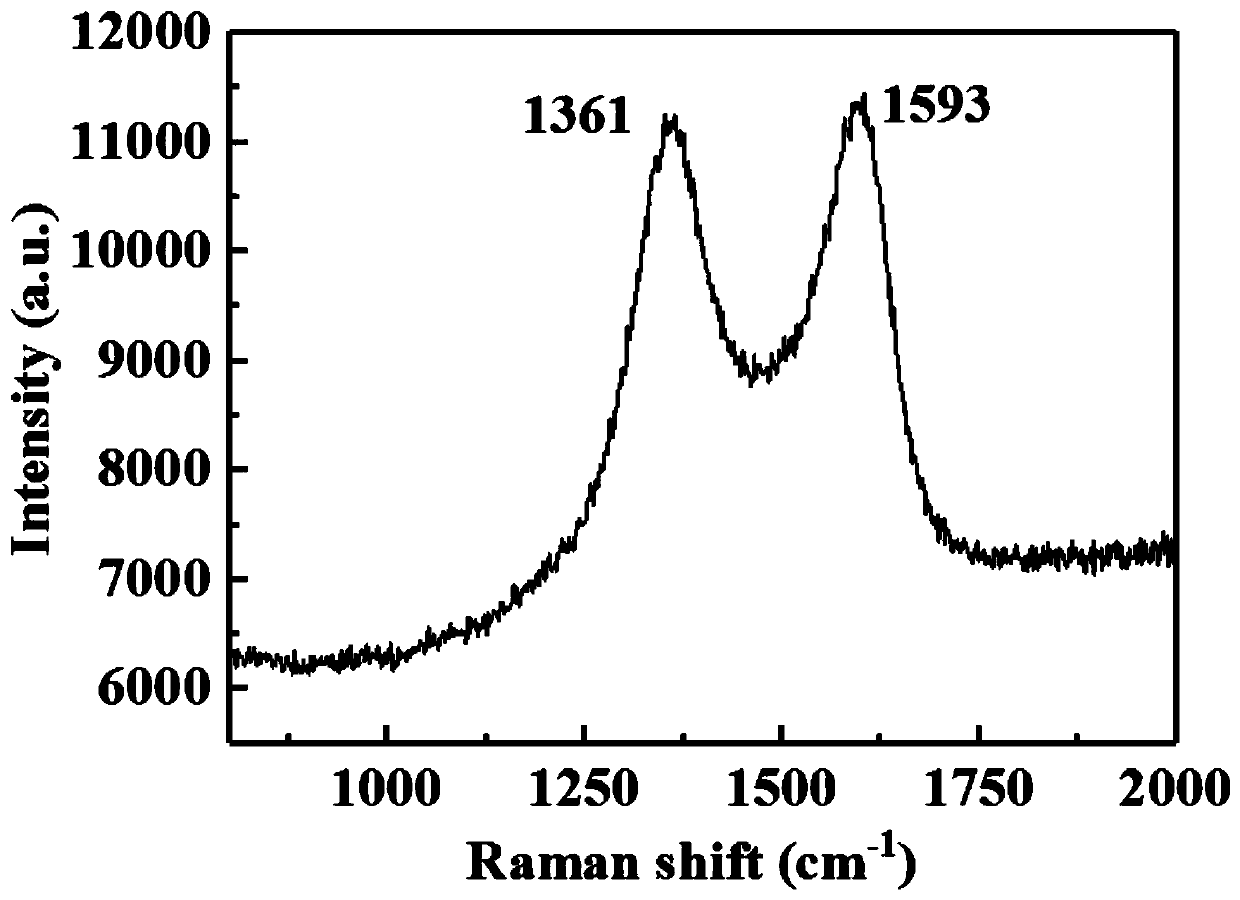

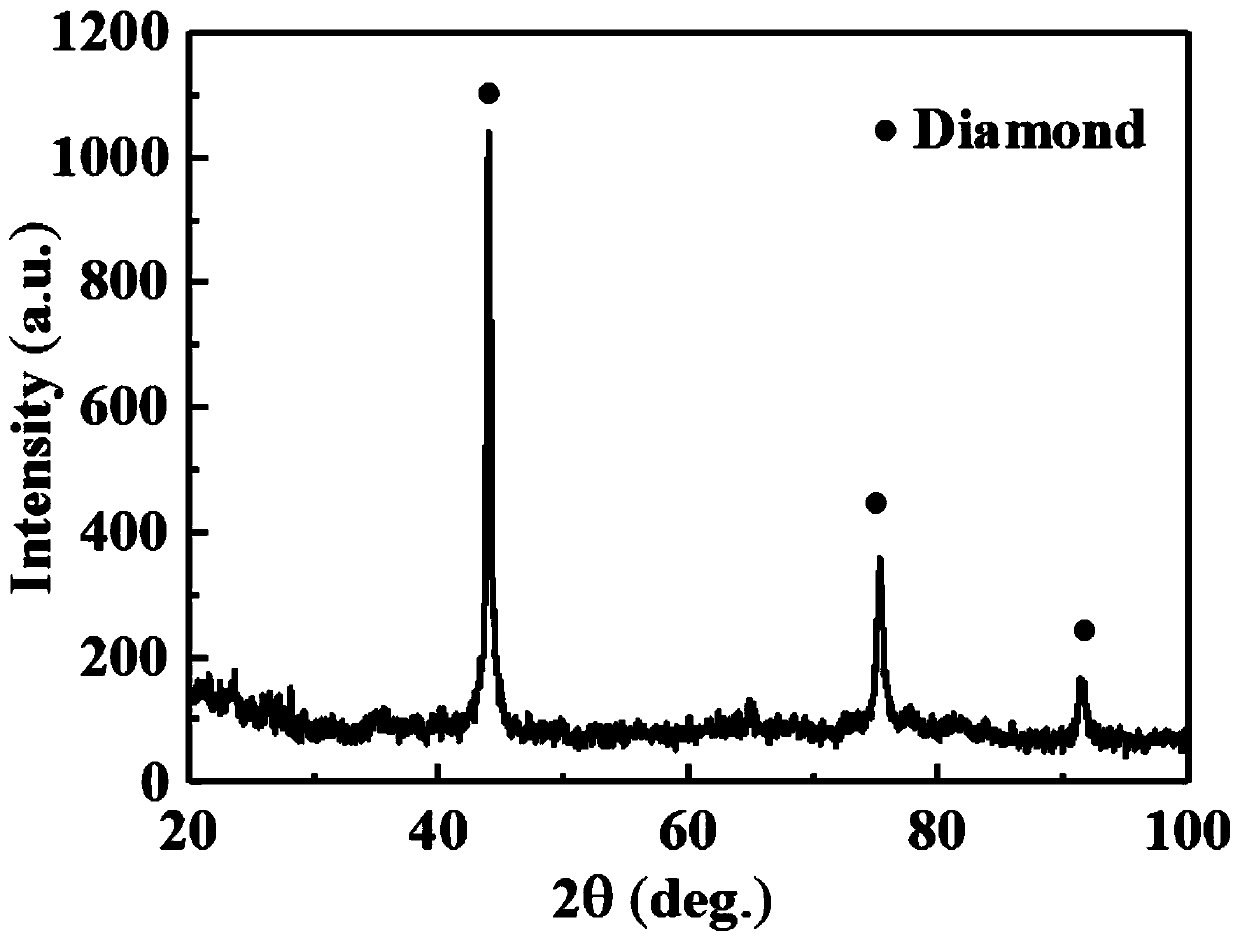

[0036] A micro-nano-scale polycrystalline diamond composite material, the composition of which includes carbon nano-onions and micro-diamonds;

[0037] The mass percentage of the micro-diamond is 20-50 wt.%, and the balance is carbon nano-onion.

[0038] The average particle size of the carbon nano-onions is 5nm;

[0039] The micro-diamond is crushed material with a particle size of 0.5-5 μm and a purity of 99%.

[0040] The Vickers hardness of the micro-nano polycrystalline diamond composite material is 30-200GPa.

Embodiment 2

[0042] A preparation method of micro-nano polycrystalline diamond composite material, comprising the following steps:

[0043] S1. Anneal the detonation nano-diamond powder with an average grain size of 5nm. In the annealing process, the vacuum degree is 1Pa, the annealing temperature is 900°C, and the temperature is not kept after the annealing, so that the carbon nanometer powder with an average grain size of 5nm is obtained. onion;

[0044] S2, select 8 mg of carbon nano-onions and add 2 mg of micron diamond grains for mixing;

[0045] S3. Fill the mixture formed by micro-diamond and carbon nano-onion into the WC cemented carbide mold for pre-pressing, the pre-pressing pressure is 400MPa, pre-pressing 10s;

[0046] S4. Putting the pre-pressed sample into a mold for sintering at high temperature and high pressure to prepare a micro-nano polycrystalline diamond composite material.

[0047]As preferably, in said step S3, WC cemented carbide mold uses LaCaO 3 As insulation m...

Embodiment 3

[0052] A preparation method of micro-nano polycrystalline diamond composite material, comprising the following steps:

[0053] S1, annealing the detonation nano-diamond powder with an average grain size of 5nm, the degree of vacuum in the annealing process is 1.0×10 -1 Pa, the annealing temperature is 1000°C, and the temperature is kept for 1h after annealing, and the carbon nano-onions with an average grain size of 5nm are obtained;

[0054] S2, select 7g of carbon nano-onions and add 2g of micron diamond grains for mixing;

[0055] S3. Fill the mixture formed by micro-diamond and carbon nano-onion into the WC cemented carbide mold for pre-pressing, the pre-pressing pressure is 500MPa, and the pre-pressing is 15s;

[0056] S4. Putting the pre-pressed sample into a mold for sintering at high temperature and high pressure to prepare a micro-nano polycrystalline diamond composite material.

[0057] As preferably, in said step S3, WC cemented carbide mold uses LaCaO 3 As insul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com