Polyphenylene sulfide nano whisker composite material and preparation method thereof

A technology of polyphenylene sulfide and nano-whiskers, which is applied in the field of polymer composite materials, can solve problems such as poor fluidity, increased density of composite materials, and limited addition amount, so as to reduce costs, improve fluidity, and increase addition amount Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

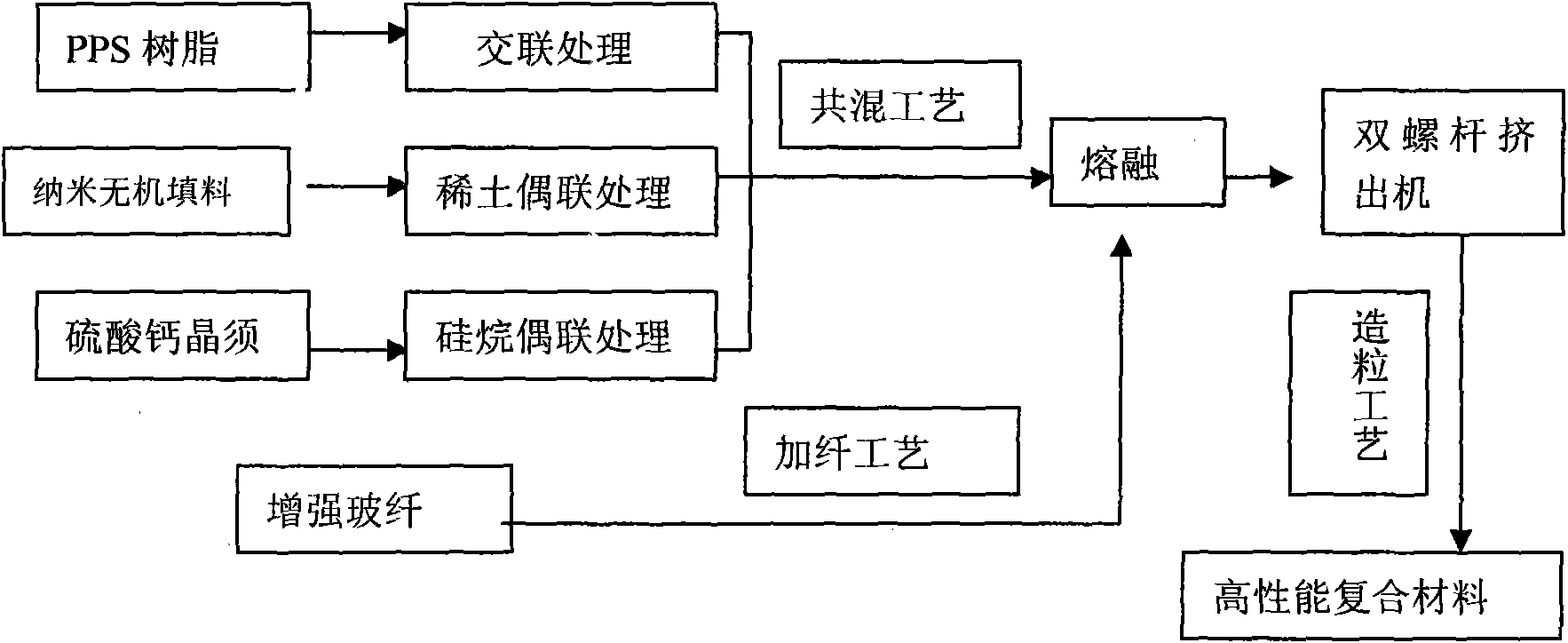

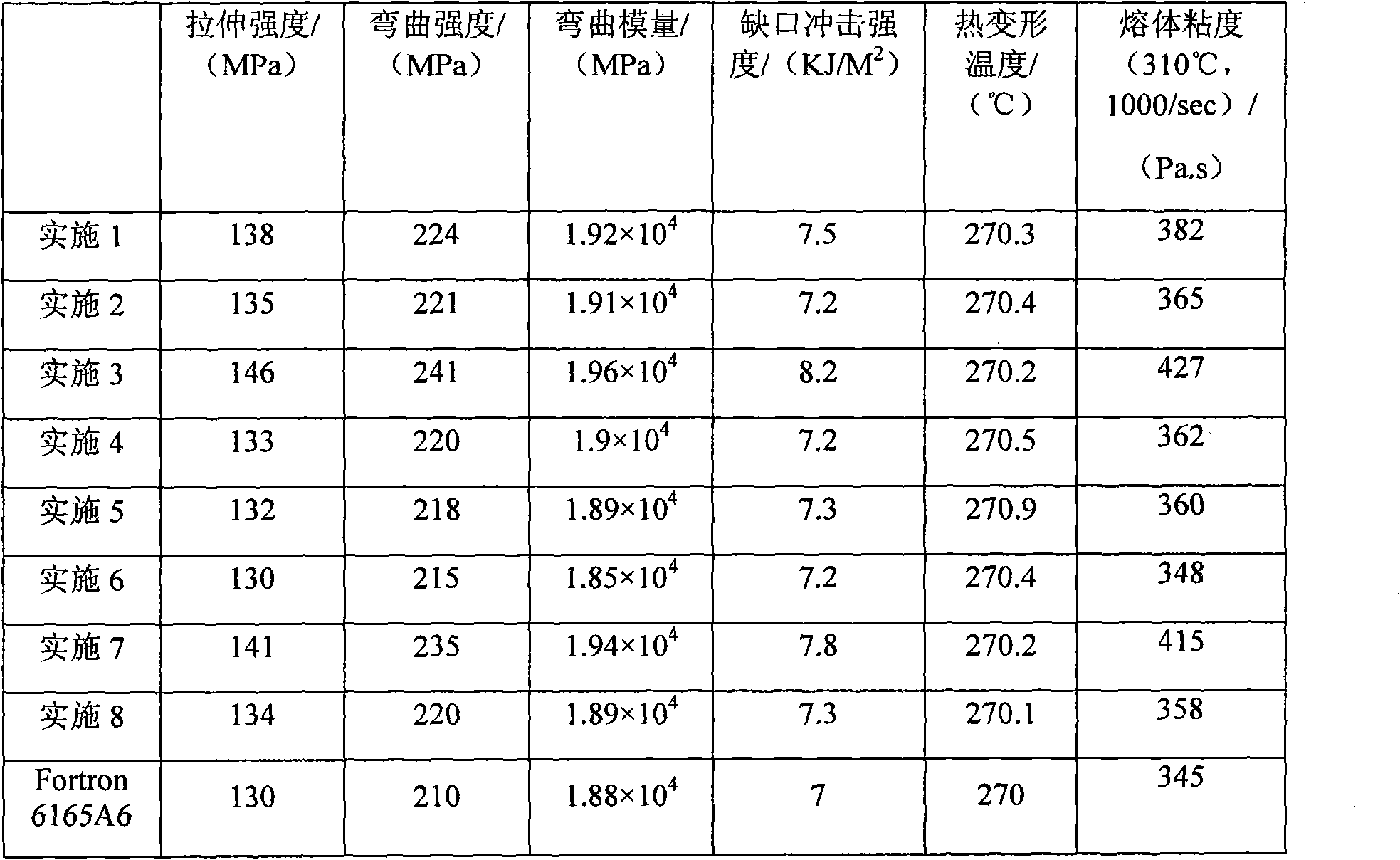

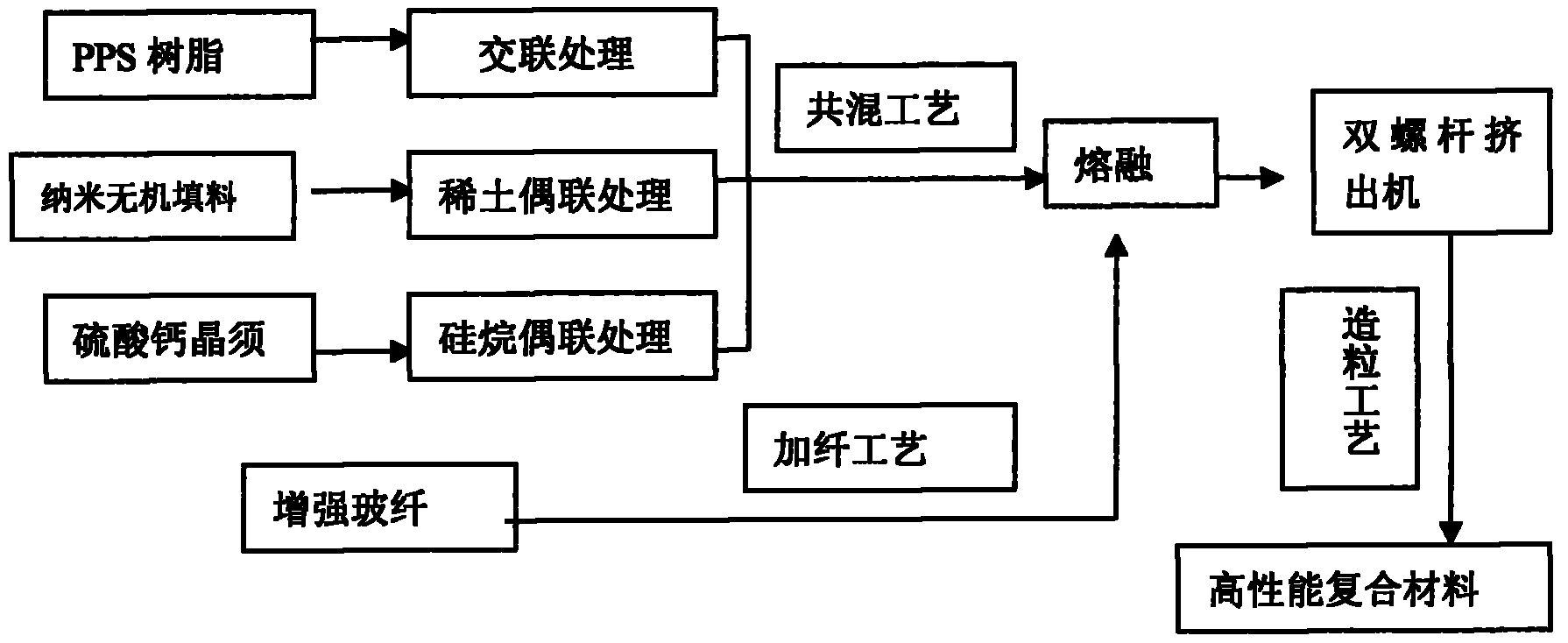

[0011] Use as figure 1 Process. 37% of the PPS resin with a molecular weight of 40,000 is put into a double cone drying cyclotron to vacuum (under oxygen-free conditions), the vacuum degree is 0.07Pa, and the temperature is increased to 220°C for 2 hours to crosslink to obtain a crosslinked PPS resin; 5% nano carbonic acid Calcium and 2% rare earth coupling agent (DN-930, Nanjing Daoning Chemical Co., Ltd.) are fully mixed in a high-speed (1000 rpm) mixer to obtain nano inorganic fillers treated with rare earth coupling agent; 15% calcium sulfate whiskers Mix well with 0.5% silane coupling agent (KH-550) in a high-speed (600 revolutions / min) mixer to obtain calcium sulfate whiskers treated with silane coupling agent; 0.5% antioxidant (1010). After the mixing treatment, the mixed materials are put into the hopper of the twin-screw extruder, melt blended, extruded and granulated to become composite material particles. Among them, the extrusion granulation processing conditions: ...

Embodiment 2

[0013] Polyphenylene sulfide crosslinking method, calcium sulfate whisker treatment method, and nano calcium carbonate treatment method are the same as in Example 1. 35% polyphenylene sulfide, 15% calcium sulfate whisker, 40% glass fiber, 8.2% nano calcium carbonate, 0.8% rare earth coupling agent, 0.5% silane coupling agent, 0.5% antioxidant. Use the above as figure 1 In the process, the mixed materials are added to the hopper of the twin-screw extruder, melted and blended, extruded and granulated into composite materials. The processing technology is the same as in Example 1, and the melt pressure is 17 MPa.

Embodiment 3

[0015] Polyphenylene sulfide crosslinking method, calcium sulfate whisker treatment method, and nano calcium carbonate treatment method are the same as in Example 1. 39% polyphenylene sulfide, 15% calcium sulfate whisker, 40% glass fiber, 2.5% nano calcium carbonate, 2.5% rare earth coupling agent, 0.5% silane coupling agent, 0.5% antioxidant. Use the above as figure 1 In the process, the mixed materials are added to the hopper of the twin-screw extruder, melted and blended, extruded and granulated into composite materials. The processing technology is the same as in Example 1, and the melt pressure is 15 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com