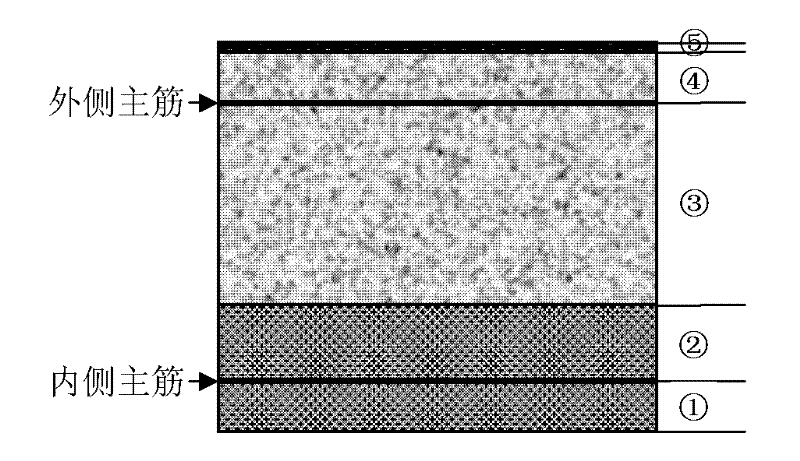

High-performance functionally-gradient shield lining segment and preparation method thereof

A gradient function and lining segment technology, which is applied in wellbore lining, tunnel lining, chemical instruments and methods, etc., can solve the problems of poor durability, easy damage, and high segment cost, and achieve improved carbonation resistance and crack resistance , The effect of reducing the overall damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

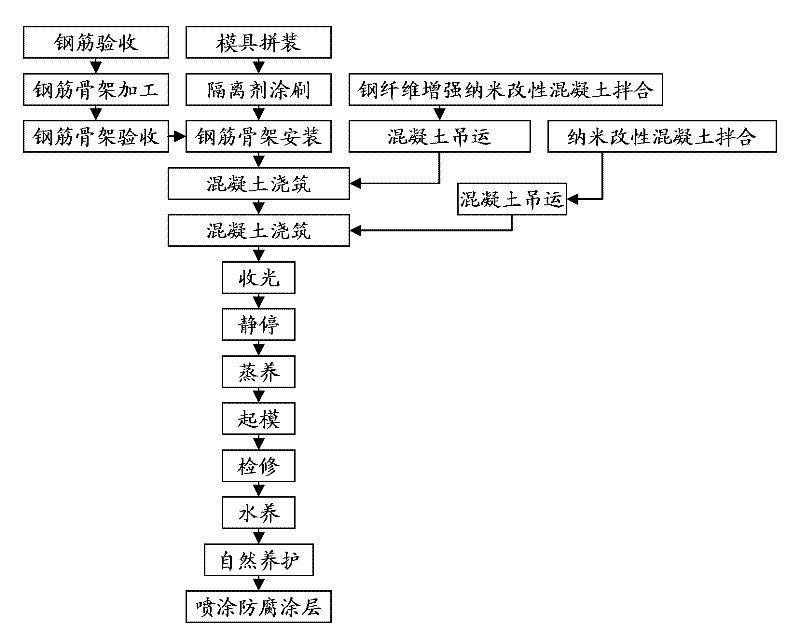

Method used

Image

Examples

Embodiment 1~4

[0036] Conch PII52.5 cement, sheared straight and slightly twisted steel fiber (produced by Jiaxing Jingwei Steel Fiber Co., Ltd.), Class II fly ash, Shagang S95 slag powder, natural medium sand, 5-25mm crushed stone, HG-PCA600 Type high-performance water reducing agent, silica sol with mass concentrations of 5%, 20% and 40% respectively to prepare steel fiber reinforced nano-modified concrete, nano-modified concrete and C50 ordinary concrete, and used for gradient functional shield lining segments Production and concrete mix ratios are shown in Table 1.

[0037] Table 1

[0038]

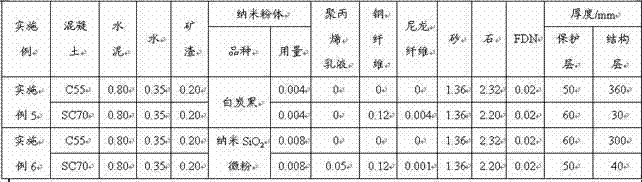

Embodiment 4~6

[0040] Conch PII52.5 cement, sheared straight and slightly twisted steel fiber (produced by Jiaxing Jingwei Steel Fiber Co., Ltd.), polypropylene emulsion and nylon fiber produced by Zhejiang Luban Building Waterproof Co., Ltd., class II fly ash, and Shagang S95 slag Micropowder, natural medium sand, 5-25mm gravel and HG-FDN type high-efficiency water reducer, white carbon black or nano-SiO 2 The micropowder was used to prepare steel fiber reinforced nano-modified concrete and nano-modified concrete, which were used in the production of functionally gradient shield lining segments. The concrete mix ratios are shown in Table 2, respectively.

[0041] Table 2

[0042]

[0043] Embodiment 4~6:

[0044] Conch PII52.5 cement, sheared straight and slightly twisted steel fiber (produced by Jiaxing Jingwei Steel Fiber Co., Ltd.), polypropylene emulsion produced by Zhejiang Luban Building Waterproof Co., Ltd., class II fly ash, Shagang S95 slag powder, natural Medium sand, 5-25m...

Embodiment 8~10

[0048] Conch PII52.5 cement, sheared straight and slightly twisted steel fiber (produced by Jiaxing Jingwei Steel Fiber Co., Ltd.), Zhejiang Luban polypropylene fiber, class II fly ash, Shagang S95 slag powder, natural medium sand, 5-25mm Crushed stone and HG-PCA600 high-performance water reducing agent are used to prepare steel fiber concrete and ordinary concrete, and are used in the production of gradient functional shield lining segments. The produced gradient functional segments are cured in water for 7-14 days and then hoisted to the segment storage yard. After natural drying for 2 days, 4 days and 5 days respectively, paint 881-H04 epoxy resin coating and JS waterproof coating on the outside of the segments , 881-Y01 type polyurethane waterproof coating and PC-40 type silicone impregnated concrete protective agent, the coating thicknesses are 2.0mm, 4.0mm, 0.3mm respectively. The concrete mix proportions are shown in Table 3.

[0049] table 3

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com