High temperature resistant, high strength modified epoxy resin adhesive and preparation thereof

An epoxy resin, high-strength technology, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of brittleness and poor temperature resistance, and achieve excellent high temperature resistance, outstanding heat resistance, excellent The effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] Preparation of polyurethane prepolymer: the polyether diol used has a number average molecular weight of 1000. Add 50g of polyether diol into a clean and dry four-necked flask, heat and keep stirring to 120°C for reflux dehydration for 1h, then cool it down to 50°C, add 17.4g of TDI, then slowly raise the temperature to 70°C, keep warm and Stir at a constant speed and react for 2 hours.

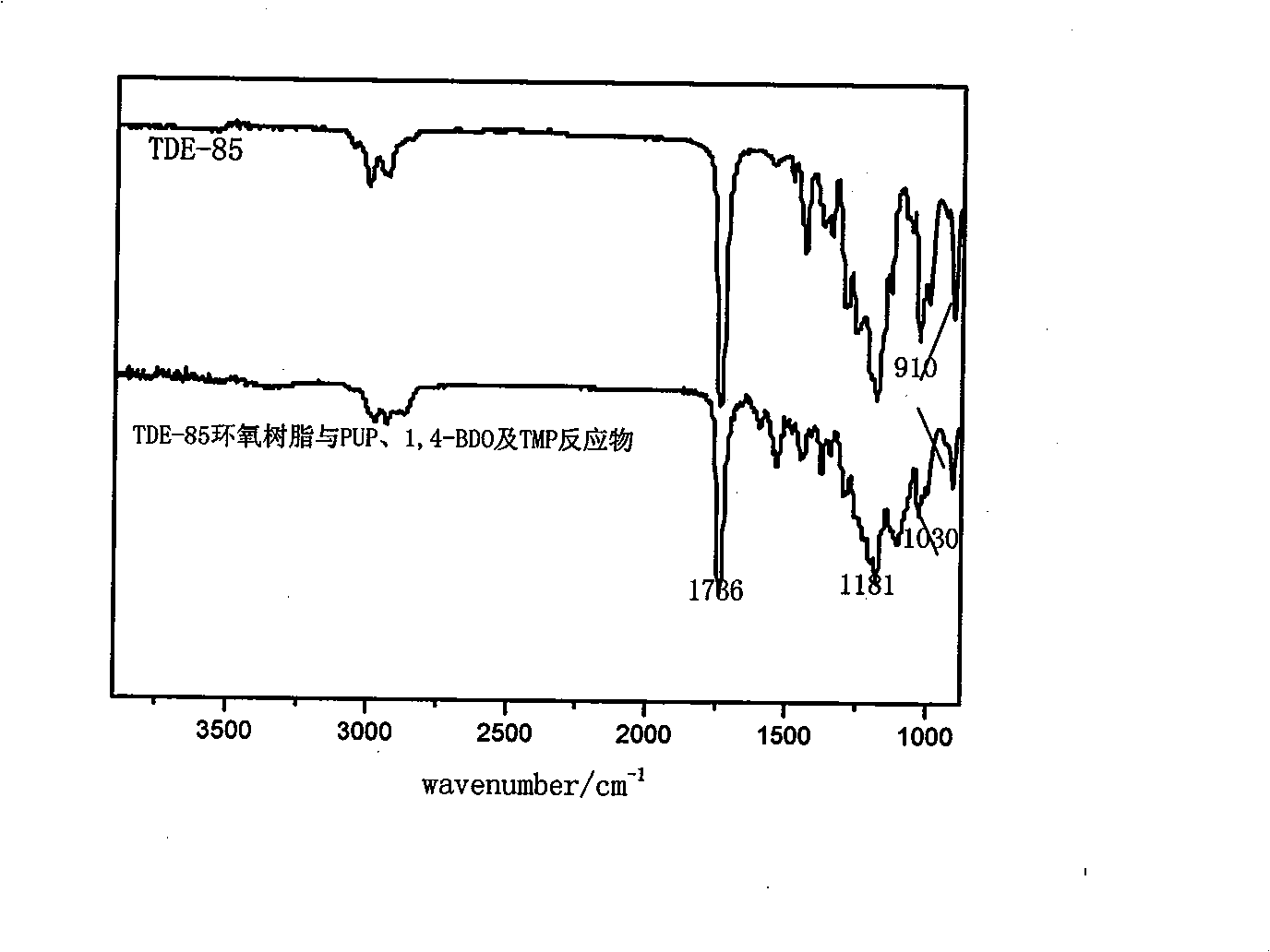

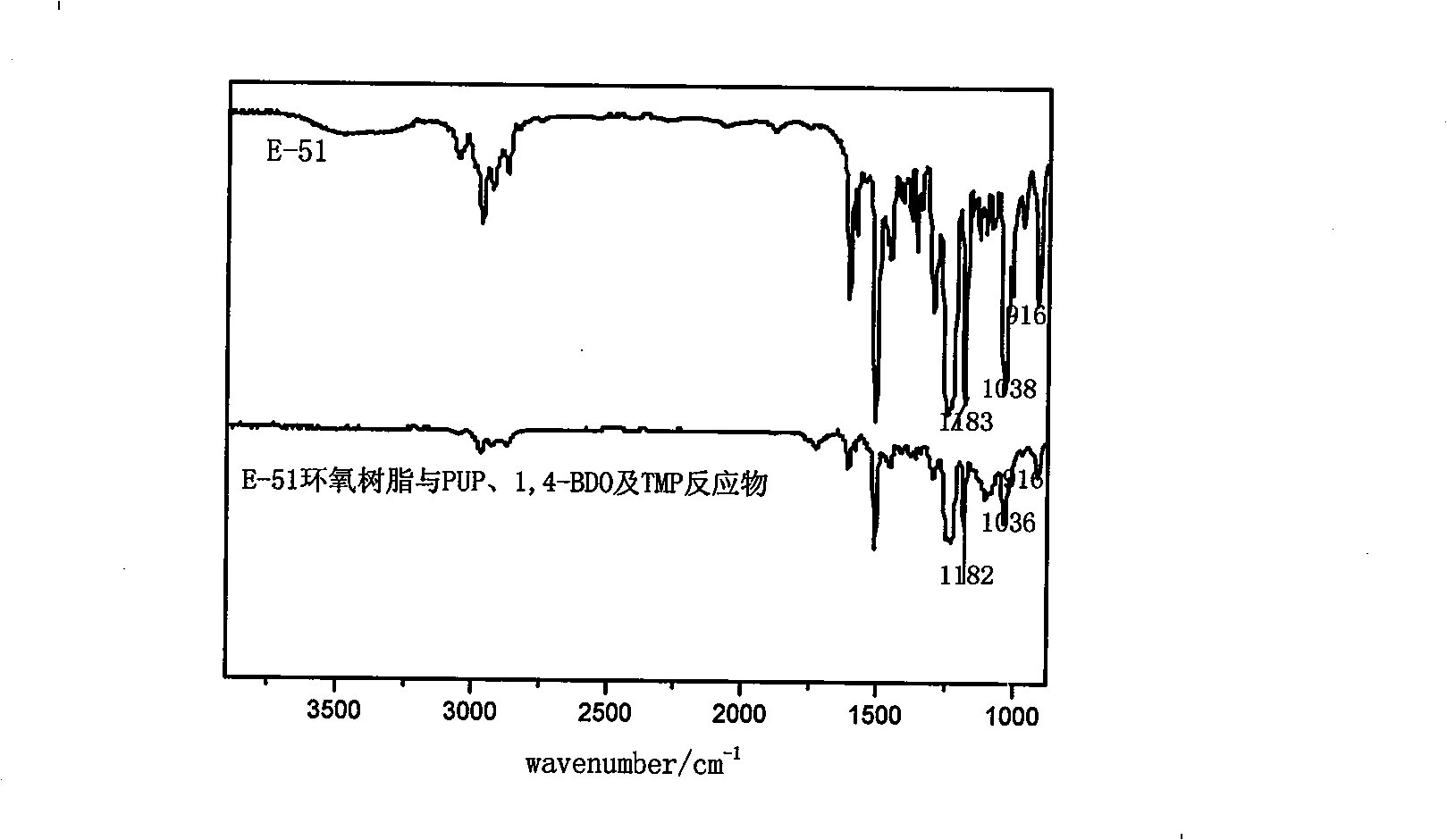

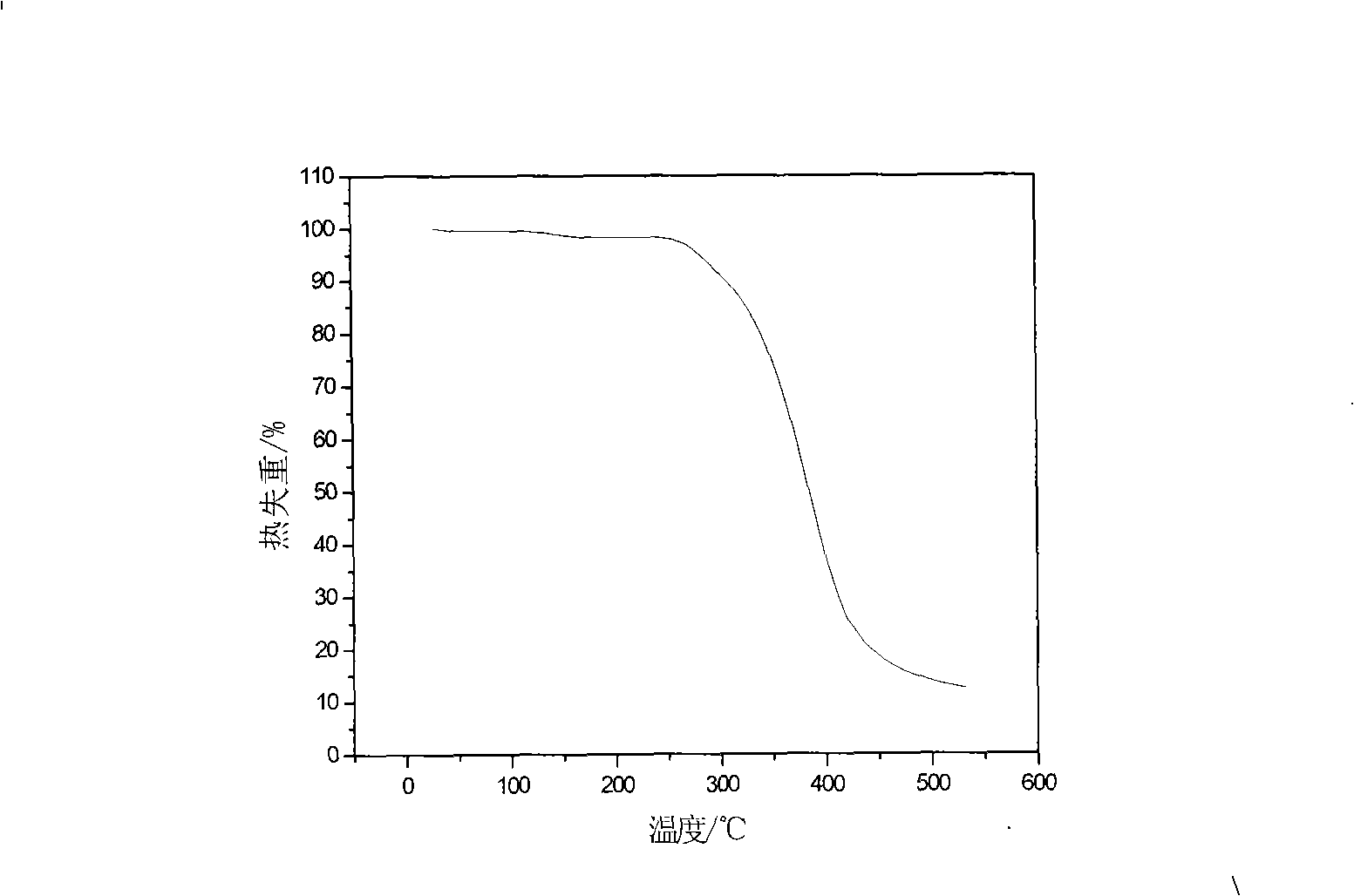

[0034] Adhesive configuration: Add 1.68g 1,4-butanediol and 0.56g trimethylolpropane to the prepared polyurethane prepolymer, stir well and then add 366.5g TDE-85 and E-51 to mix (mass ratio 1:1) epoxy resin, reacted at 100°C for 1 hour. Take 54.52g each of m-phenylenediamine and diaminodiphenylmethane, mix them uniformly in a beaker, keep the temperature at 110°C for 15 minutes, and cool to room temperature to make a supercooled liquid. Finally, the supercooled liquid was mixed with polyurethane epoxy resin at room temperature, and then 13.08 g of 2-ethyl-4-methylimidazole accelerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com