Nylon/ethane-ethenol copolymer commixed type lamination barrier material and its preparation method

A barrier material, vinyl alcohol technology, applied in the field of polymer materials and preparation, can solve problems such as unsatisfactory barrier effect and narrow application range, and achieve the effects of improving impact toughness, barrier performance and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

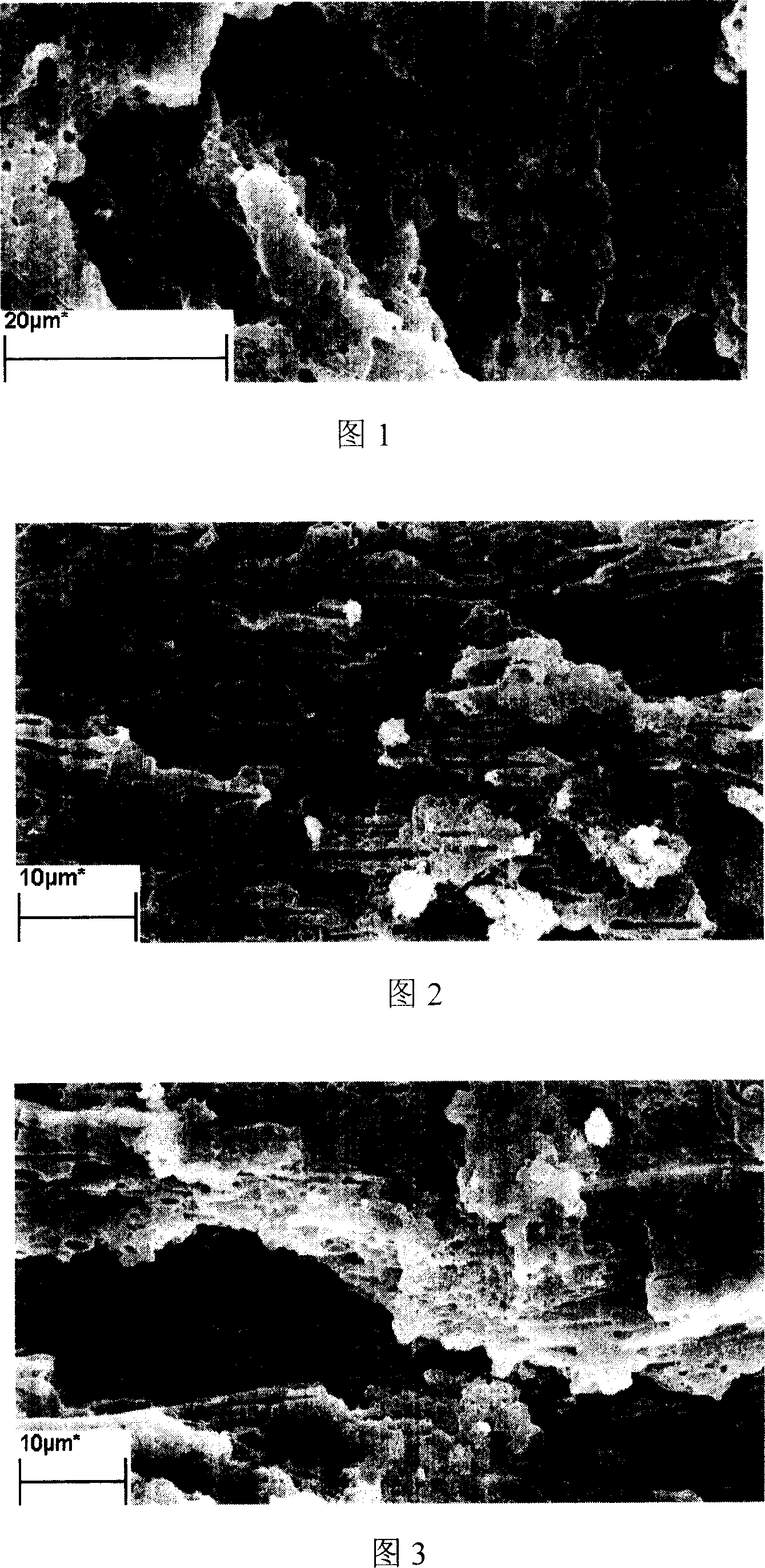

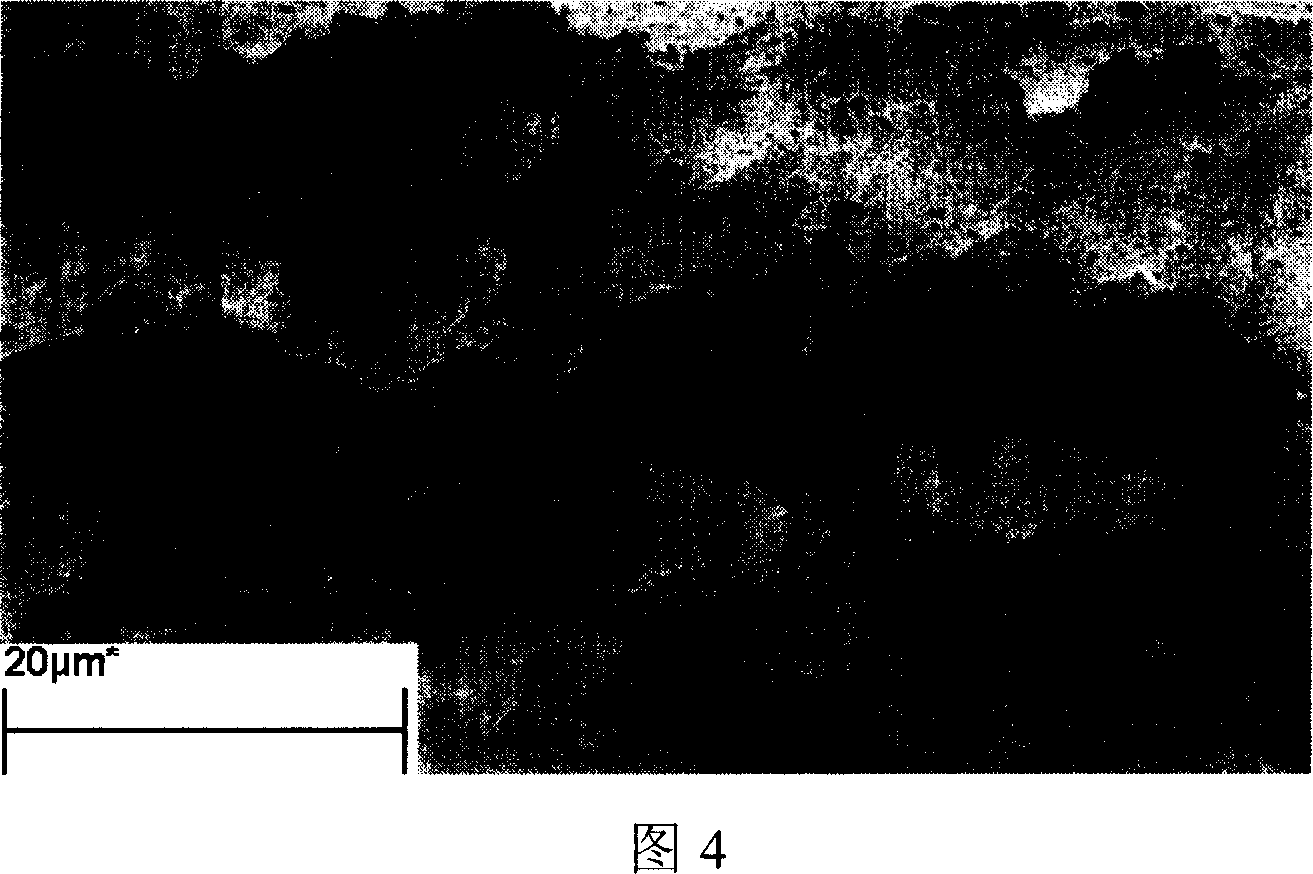

Image

Examples

Embodiment 1

[0034] A nylon / ethylene-vinyl alcohol copolymer blended laminate barrier material is prepared from the following raw materials in mass percentage:

[0035] Nylon 95%, ethylene-vinyl alcohol copolymer (EVOH) 5%, and nylon and ethylene-vinyl alcohol copolymer (EVOH) 1.5% peroxide by weight.

[0036] The nylon is nylon 6, nylon 11, nylon 12 or nylon 1212.

[0037] The molar content of the ethylene component in the EVOH is 28%.

[0038] Peroxides are organic peroxides, including hydroperoxides, dialkyl peroxides DCP (dicumyl peroxide), diacyl peroxides BPO (dibenzoyl peroxide), etc., peroxides Esters, peroxydicarbonates. Dicumyl peroxide is preferred.

[0039] The preparation method is to mix the three materials uniformly, control the temperature at 220° C., blend, extrude and granulate through a screw extruder.

Embodiment 2

[0041] A nylon / ethylene-vinyl alcohol copolymer blended laminate barrier material is prepared from the following raw materials in mass percentage:

[0042] Nylon 90%, ethylene-vinyl alcohol copolymer (EVOH) 10%, and nylon and ethylene-vinyl alcohol copolymer (EVOH) 1.5% peroxide by weight.

[0043] The nylon is nylon 6.

[0044] The molar content of the ethylene component in the ethylene-vinyl alcohol copolymer (EVOH) is 48%.

[0045]Peroxides are organic peroxides, including hydroperoxides, dialkyl peroxides DCP (dicumyl peroxide), diacyl peroxides BPO (dibenzoyl peroxide), etc., peroxides Esters, peroxydicarbonates. Dibenzoyl peroxide is preferred.

[0046] The preparation method is as follows: after mixing the three materials evenly, the temperature is controlled at 190° C., blending, extruding and granulating through a screw extruder.

Embodiment 3

[0048] A nylon / ethylene-vinyl alcohol copolymer blended laminate barrier material is prepared from the following raw materials in mass percentage:

[0049] Nylon 85%, ethylene-vinyl alcohol copolymer (EVOH) 15%, and nylon and ethylene-vinyl alcohol copolymer (EVOH) 1.5% peroxide by weight.

[0050] The nylon is nylon 11.

[0051] The molar content of the ethylene component in the ethylene-vinyl alcohol copolymer (EVOH) is 38%.

[0052] Peroxides are organic peroxides, including hydroperoxides, dialkyl peroxides DCP (dicumyl peroxide), diacyl peroxides BPO (dibenzoyl peroxide), etc., peroxides Esters, peroxydicarbonates. Peroxyesters are preferred.

[0053] The preparation method is to mix the three materials uniformly, control the temperature at 200° C., blend and extrude to granulate through a screw extruder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com