Bismaleimide containing 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) and asymmetric in molecular structure as well as preparation method and application of bismaleimide in preparation of composite resin

A technology of bismaleimide and molecular structure, which is applied in the field of microelectronic packaging materials, can solve the problems of reducing resin performance, reducing heat resistance, and difficulty in meeting flame retardant requirements, and achieves the effect of solving poor solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1 Preparation of asymmetric dibasic primary amines containing DOPO

[0048] The asymmetric dibasic primary amine containing DOPO shown in general formula (I) is carried out with reference to the method disclosed in the existing literature (Journal of Polymer Science: Part A: Polymer Chemistry, Vol.49, 1331-1340 (2011)) Preparation, the synthetic route is shown in the following formula:

[0049]

[0050] Among them, R 1 is a hydrogen atom, C 1 -C 6 Alkyl, C 1 -C 6 Alkoxy, -CF 3 or a halogen atom;

[0051] R 2 is a hydrogen atom, methyl, 2,6-dimethyl, methoxy or allyl;

[0052] R3 is a hydrogen atom, methyl, 2,6-dimethyl, ethyl or methoxy;

[0053] R 4 is a hydrogen atom, C 1 -C 6 Alkyl, -CF 3 or benzene ring;

[0054] X is O or S;

[0055] x 1 is OH or SH;

[0056] x 2 is F or Cl;

[0057] with R 1 , R 2 and R 3 Take hydrogen atom, R respectively 4 Take -CH 3 , X takes O, X 1 Take OH, X 2 Taking F as an example, the detailed synthetic...

Embodiment 2

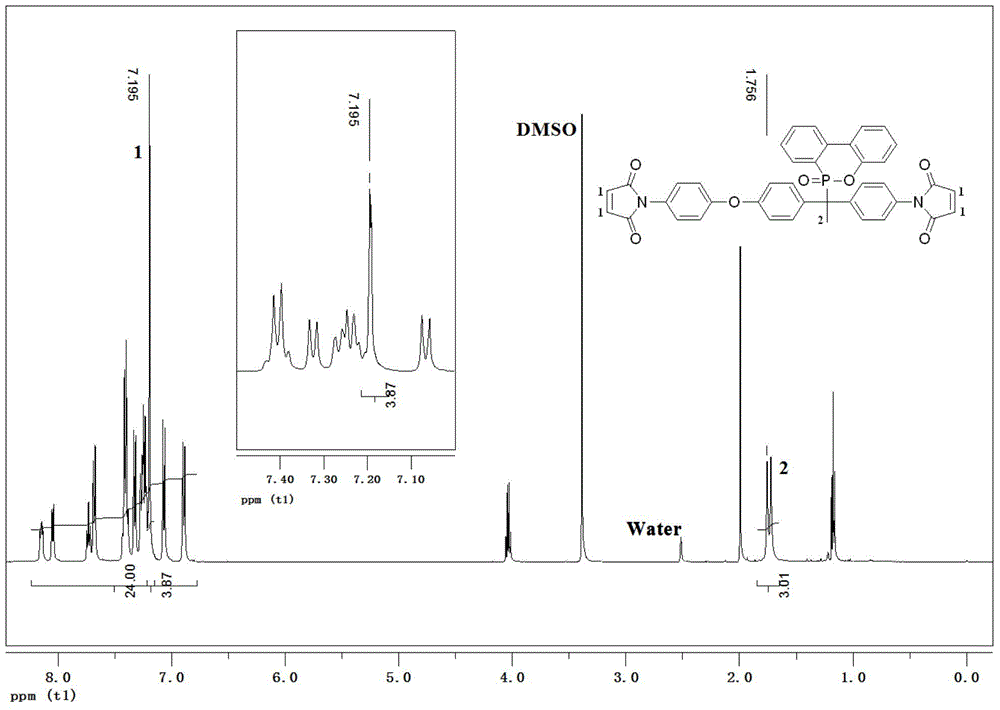

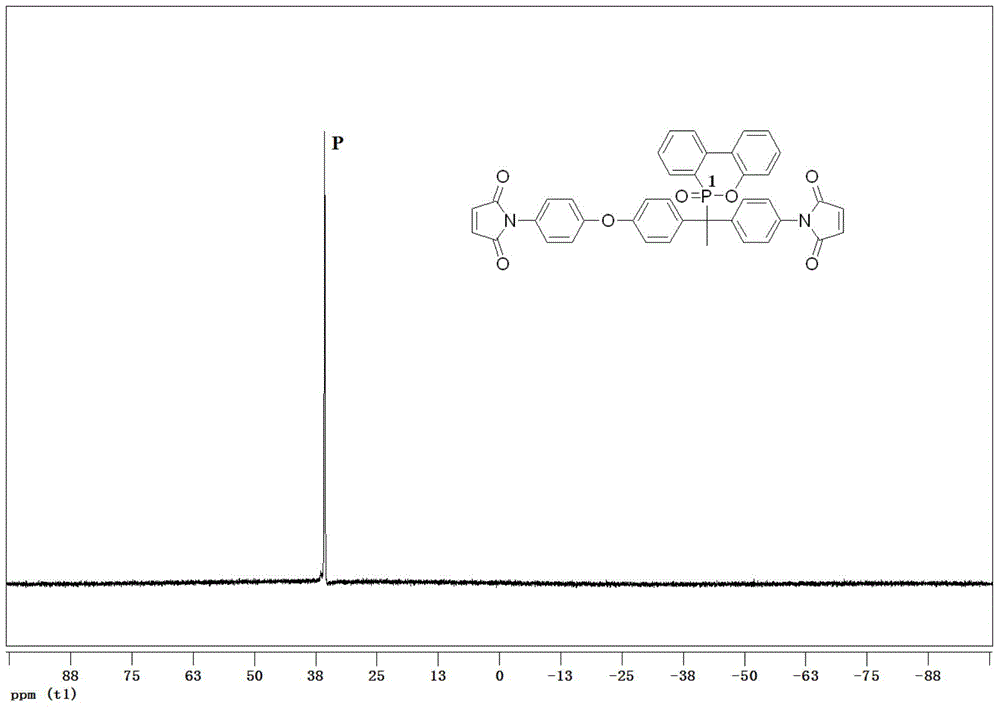

[0062] Example 2 Preparation of Bismaleimide Monomer Containing DOPO and Asymmetric Molecular Structure by Method 1

[0063] with R 1 , R 2 , R 3 and R 5 Take hydrogen atom, R respectively 4 Take -CH 3 , X takes O, and the mixed solvent containing toluene takes toluene / DMF (volume ratio is 2 / 1) mixed solution as example, through the first kind of preparation method provided by the present invention, with the formula (I- 1) The asymmetric dibasic primary amine containing DOPO shown in 1) prepares the compound shown in the following formula (II-1):

[0064] 1-(4'-maleimidophenyl)-1-(4'-(4"-maleimidophenoxy)phenyl-1-(10'-(9',10 '-Dihydro-9'-oxa-10'-phosphaphenanthrene-10'-oxide) ethane,

[0065] 1-(4'-maleimido)phenyl-1-[4'-(4”-maleimido)phenoxyl]phenyl-1-[(9,10-dih ydro-9-oxa-10-phosphaphenanthrene)-10-yl] ethane:

[0066]

[0067] Weigh 5.18g (0.01mol) of the formula (I-1) prepared in Example 1 containing DOPO dibasic primary amine, and add 1.96g (0.02mol) of maleic...

Embodiment 3

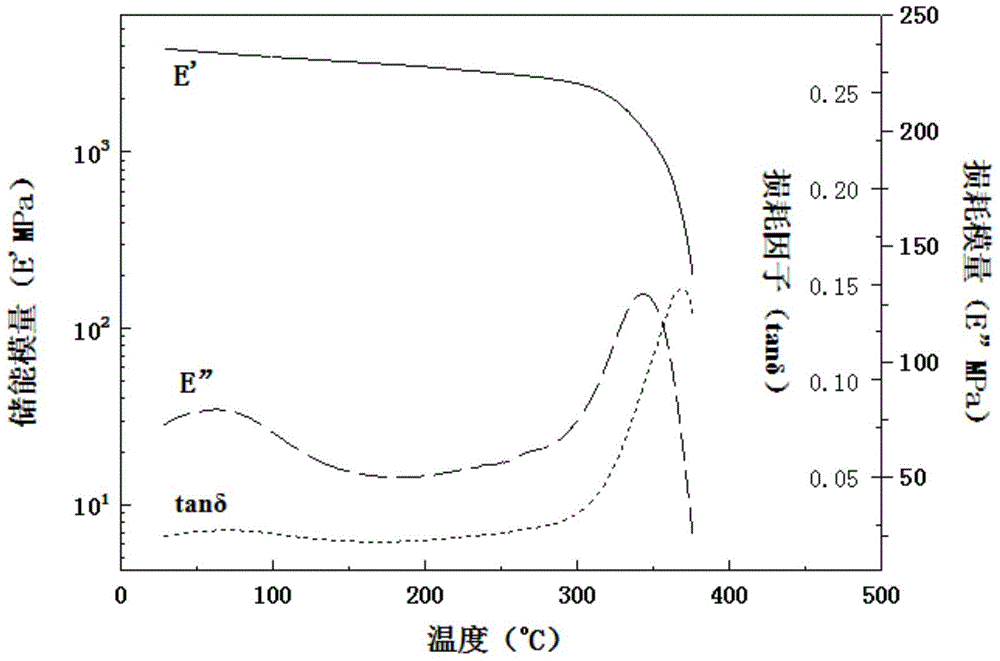

[0070] Embodiment 3 Further preparation of cyanate ester composite resin with the monomers prepared in Example 2

[0071] The bismaleimide monomer containing DOPO shown in the formula (II-1) prepared in Example 2 is used to prepare BT composite resin, the cyanate is bisphenol A cyanate, and no allylphenols are added. Compounds, epoxy resins, catalysts:

[0072] Weigh 80 parts by mass of the bismaleimide shown in formula (II-1) prepared in Example 1 and 20 parts by mass of bisphenol A cyanate, melt and blend for 10 minutes at 140 ° C and immediately pour into aluminum and degassed at 180°C. After no obvious air bubbles, cured at 230°C for 2 hours and 300°C for 8 hours to obtain cured BT resin.

[0073] The BT composite resin prepared in this example has good solubility and can be dissolved in low boiling point and low toxicity solvents such as methanol, acetone, methylene chloride and tetrahydrofuran, and has high modulus and high glass transition temperature after curing , the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Storage modulus | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com