A flame-retardant and heat-insulating polyvinyl chloride foam material and its preparation method

A polyvinyl chloride foam and glycidyl ether technology, which is applied in the field of foam materials, can solve the problems of high addition amount, reduced thermal conductivity of foam materials, poor thermal insulation performance and heat resistance performance of foam materials, etc. Effects of Small Cell Diameter, Excellent Thermal Insulation and Heat Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

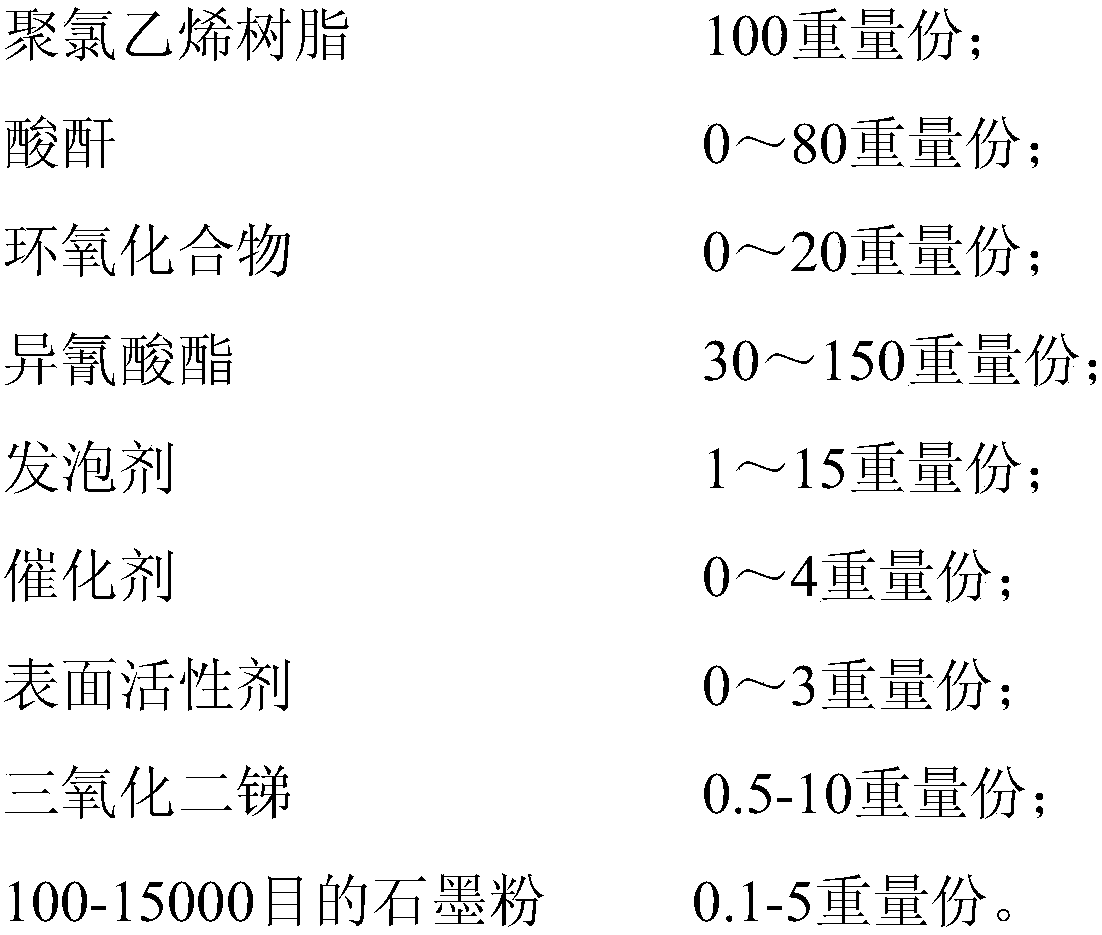

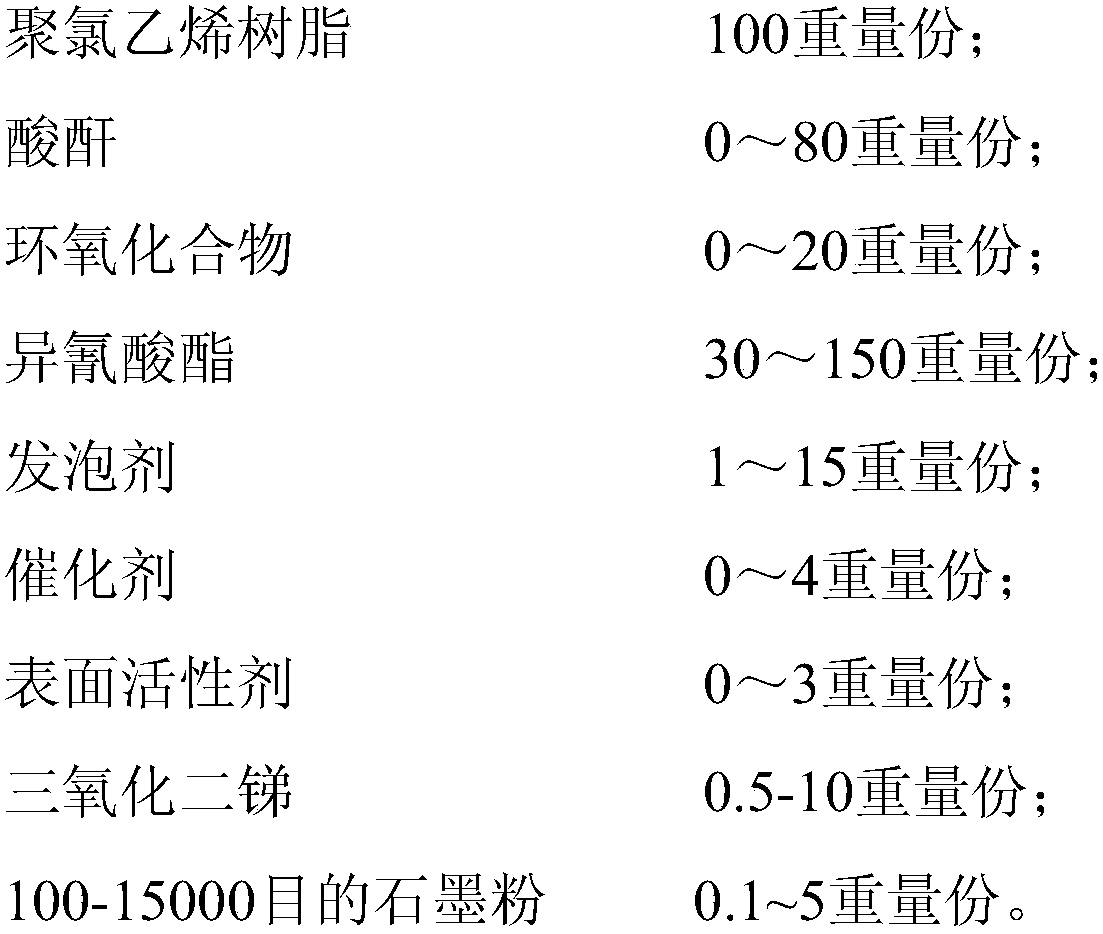

[0032] The polyvinyl chloride foam material of flame-retardant heat insulation, by the polyvinyl chloride resin of 100 weight parts, the phthalic anhydride of 80 weight parts, the bisphenol A glycidyl ether of 20 weight parts, the TDI of 30 weight parts, the TDI of 15 weight parts Parts of AIBN, 4 parts by weight of N', N", N"'-tris(dimethylaminopropyl) symmetrical hexahydrotriazine, 3 parts by weight of Tween 80, 10 parts by weight of antimony trioxide and 5 parts by weight of graphite powder (100 mesh) composition.

[0033] Preparation of the above-mentioned flame-retardant and heat-insulating polyvinyl chloride foam material: After mixing the above-mentioned components uniformly by weight, put them into the mold, preheat at 50°C for 30min, then increase the pressure to 30MPa, raise the temperature to 150°C, and press The time is 50s / mm, and finally the mold is opened after cooling to 40°C to obtain a foamed molded article; then, the obtained foamed molded article is subject...

Embodiment 2

[0035] The flame-retardant and heat-insulating polyvinyl chloride foam material consists of 100 parts by weight of polyvinyl chloride resin, 150 parts by weight of liquefied MDI, 1 part by weight of AC, 2 parts by weight of indole, 2 parts by weight of DC-193, 5 It consists of antimony trioxide in parts by weight and graphite powder (15000 mesh) in parts by weight.

[0036] Preparation of the above-mentioned flame-retardant and heat-insulating polyvinyl chloride foam material: After mixing the above-mentioned components uniformly by weight, put them into the mold, preheat at 110°C for 5 minutes, then increase the pressure to 11MPa, raise the temperature to 200°C, and press The time is 30s / mm, and finally the mold is opened after cooling to 90°C to obtain a foamed molded object; then, in water vapor, the obtained foamed molded object is subjected to secondary foaming and solidification, and the temperature of the secondary foaming is 100°C , the curing temperature is 70°C, and ...

Embodiment 3

[0038] The polyvinyl chloride foam material of flame-retardant heat insulation, by the polyvinyl chloride resin of 100 weight parts, the succinic anhydride of 50 weight parts, the tetrahydrophthalic anhydride of 10 weight parts, the glycerol glycidyl ether of 10 weight parts, 60 weight parts PAPI, 10 parts by weight of blowing agent H, 3 parts by weight of Tween 80, 5 parts by weight of antimony trioxide and 0.1 parts by weight of graphite powder (400 mesh).

[0039] Preparation of the above-mentioned flame-retardant and heat-insulating polyvinyl chloride foam material: After mixing the above-mentioned components uniformly by weight, put them into the mold, preheat at 90°C for 20min, then increase the pressure to 15MPa, raise the temperature to 180°C, and press The time is 40s / mm, and finally cooled to 110°C and then the mold is opened to obtain a foamed molded object; then, in water, the obtained foamed molded object is subjected to secondary foaming and curing, the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com