High thermotolerance polylactic acid composite material filled by french chalk and method for preparing same

A composite material and talc technology are applied in the field of talc-filled biodegradable polylactic acid composite materials and their preparation fields, which can solve the problems of affecting the biodegradability of products, long isothermal crystallization treatment time, low production efficiency, and the like. The effect of short annealing time, strong processing performance and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 100 parts of vacuum-dried polylactic acid were melted and blended in a kneader at a temperature of 190 ° C and a speed of 32 rpm for 4 minutes, and then melted and blended for 4 minutes at a speed of 64 rpm, and then in a thermocompression molding machine at a temperature of 190°C and 15 MPa pressure for 5 minutes, and finally the hot-pressed sample was annealed at 120°C for 5 minutes to form a 4.0mm sheet. Its mechanical properties and heat resistance are listed in Table 1.

Embodiment 2

[0040] 98 parts of vacuum-dried semi-crystalline poly L-lactic acid, 1 part of talc powder, 0.2 part of heat stabilizer maleic anhydride, 0.5 part of talc surface passivator GT7072, 0.3 part of lubricant aluminum stearate in a kneader In the process, melt blending at a temperature of 190°C and a speed of 32rpm for 4min, then melt blending at a speed of 64rpm for 4min, and then heat in a thermocompression molding machine at a temperature of 190°C and a pressure of 15MPa. Press molding for 5 minutes, and finally anneal the hot-pressed sample at 120°C for 4 minutes to form a 4.0mm sheet. Its mechanical properties and heat resistance are listed in Table 1.

Embodiment 3

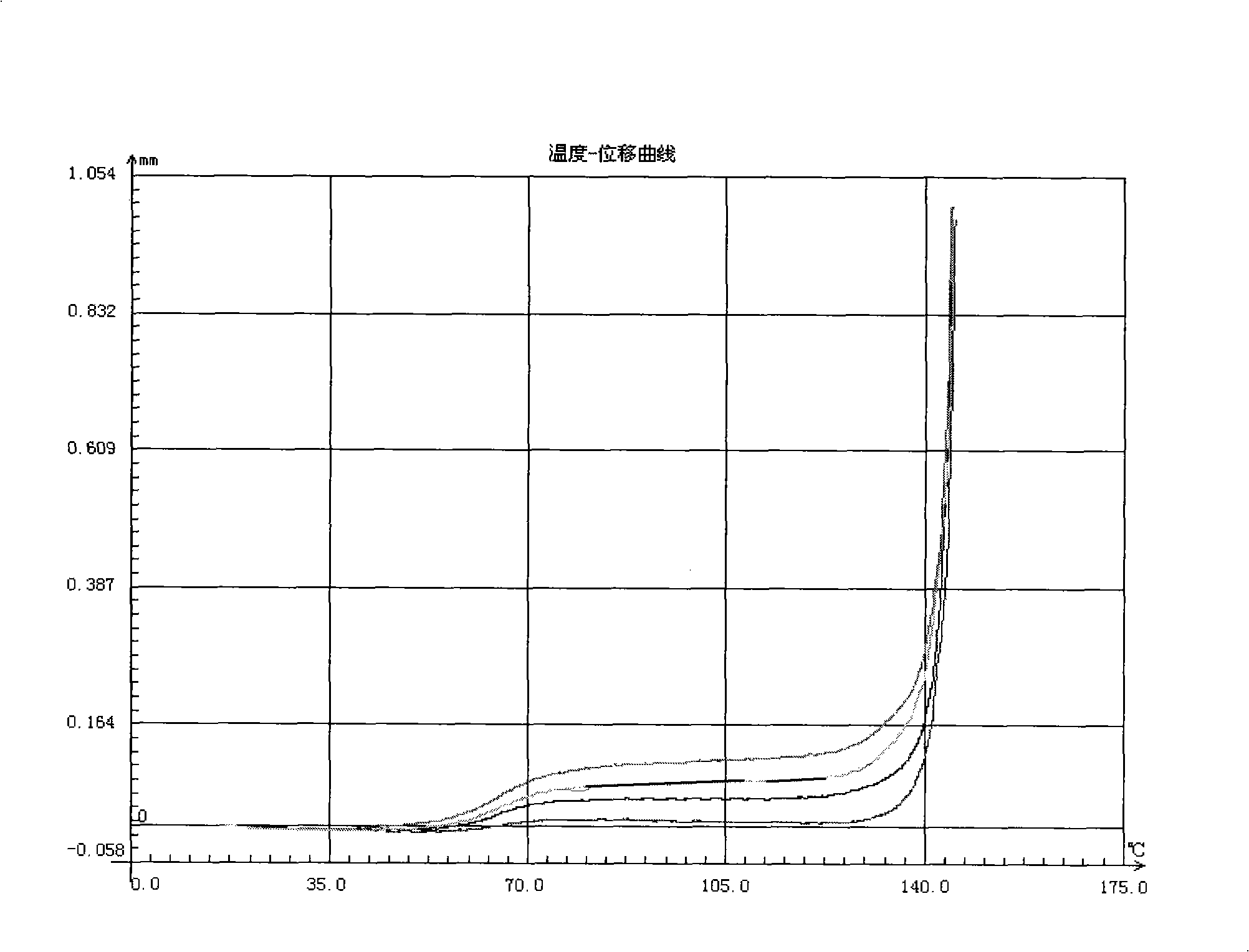

[0042]Vacuum-dried semi-crystalline poly L-lactic acid 94 parts, modified talc powder 5 parts, heat stabilizer maleic anhydride 0.2 part, talcum powder surface passivator epoxy resin Araldite GT7072 0.5 part, lubricant stearic acid 0.3 parts of aluminum were melt blended in a kneader at a temperature of 190°C and a speed of 32rpm for 4 minutes, and then melted and blended at a speed of 64rpm for 4 minutes, and then in a thermocompression molding machine at a temperature of 190°C and a pressure of Under the condition of 15MPa, it was hot-pressed for 5 minutes, and finally the hot-pressed sample was annealed at 120°C for 5 minutes to form a 4.0mm sheet. Its mechanical properties and heat resistance are listed in Table 1. The displacement-temperature curve of its Vicat test is shown in Figure 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com