Method for preparing modified carbon nanotube and ferrite and polyimide composite absorbing material

A composite wave absorbing material, carbon nanotube technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of high thermal expansion coefficient, limit wider application in aerospace, net charge accumulation, etc., to improve mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

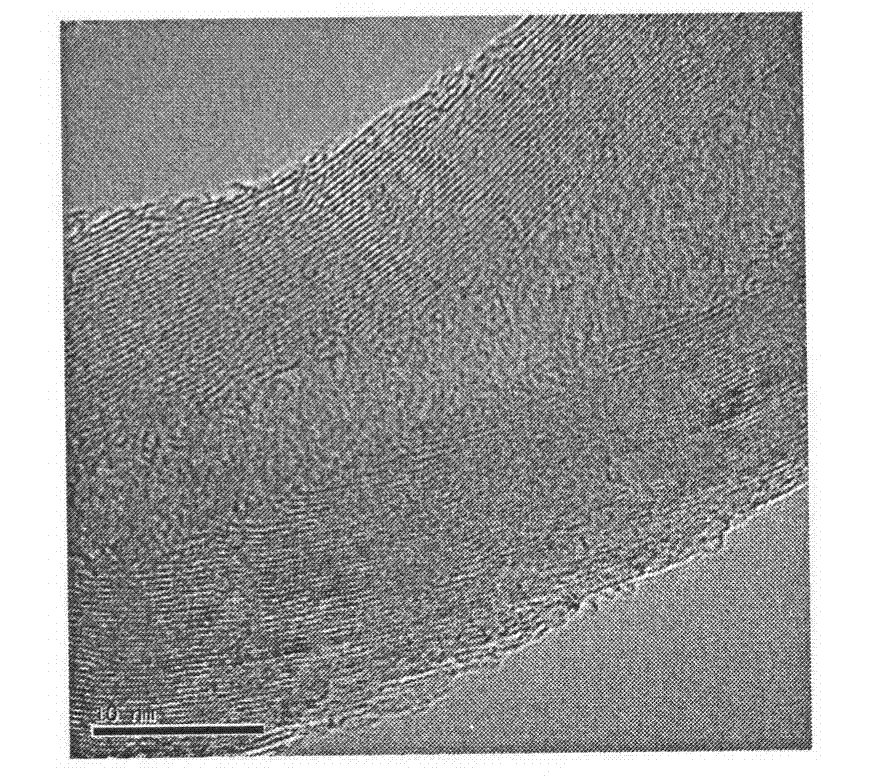

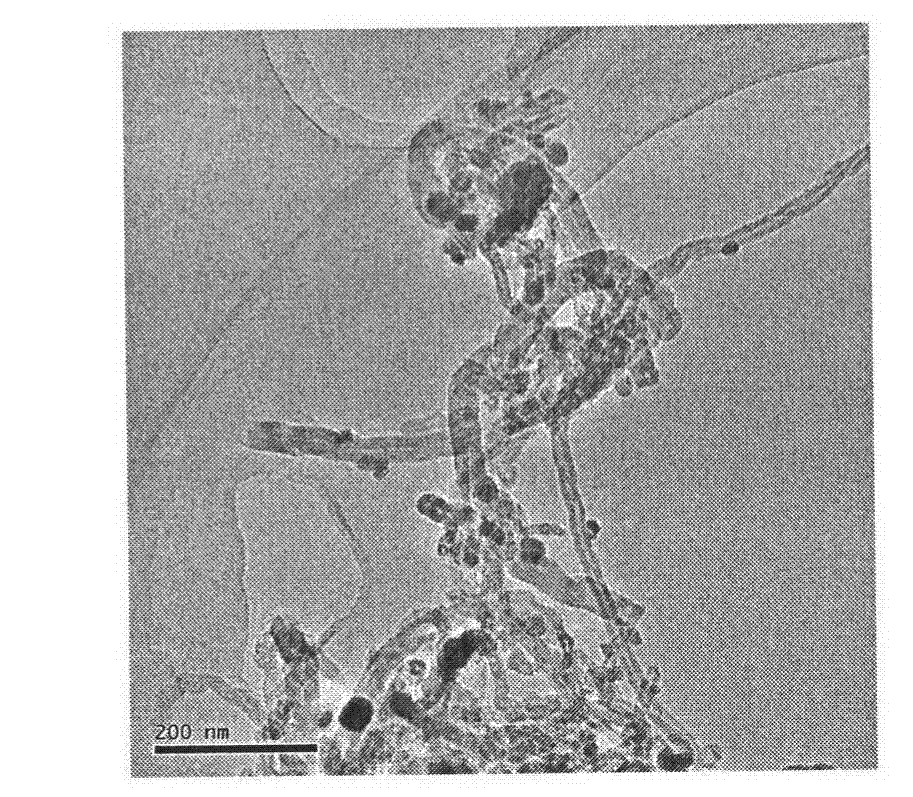

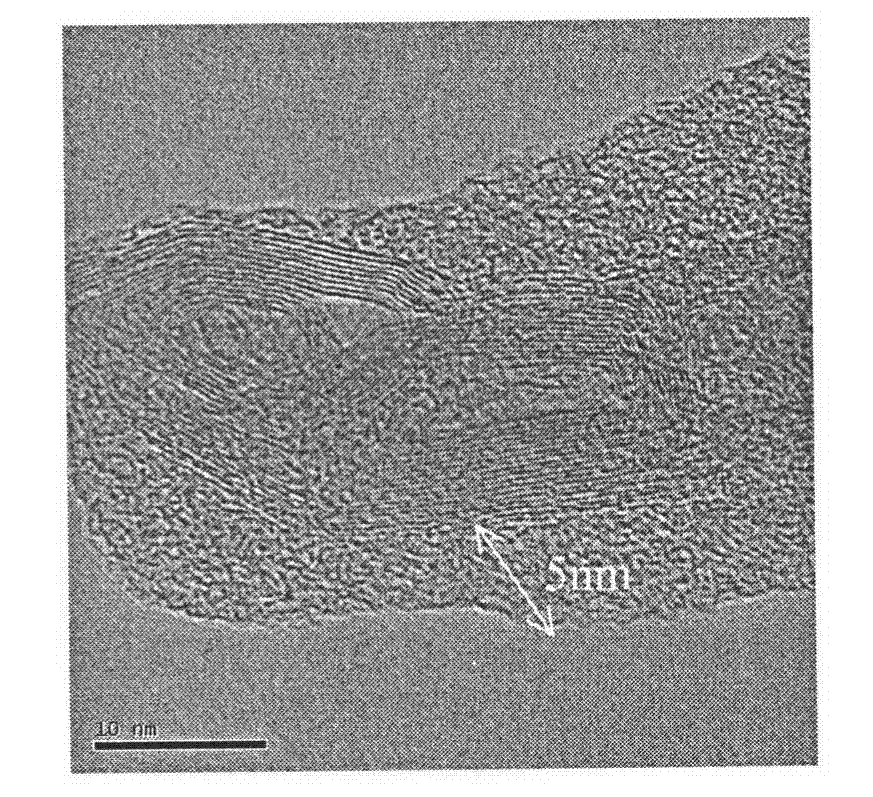

[0024]At a temperature of 25°C, take 1g of multi-walled carbon nanotubes with an average length of 0.85-1.5μm and a diameter of 10-50nm and put them into a plasma discharge device, introduce argon gas, discharge voltage at 50V, and discharge current at 0.2A. The time was 5min; 1g of plasma-modified carbon nanotubes was mixed with 50ml of deionized water in a three-necked flask and stirred evenly, and 4.04g of Fe(NO 3 ) 3 9H 2 O, 0.73gCo(NO 3 ) 2 ·6H 2 O, 0.73gNi(NO 3 ) 2 ·6H 2 O nitrate was added to the carbon nanotube aqueous solution, and after fully stirring for 2.5-3 hours, 0.0059 g / ml KOH solution was slowly dropped into the solution until the pH value of the solution was 9-10. After stirring at a temperature of 25°C for 23-24h, filter the filter cake with ultrafiltration membrane and wash the filter cake with deionized water until it is neutral, dry it at a temperature of 60°C for 1.5h and grind it, and the powder after grinding reaches the micron level. Under a ...

Embodiment 2

[0026] At a temperature of 25°C, take 1g of multi-walled carbon nanotubes with an average length of 0.85-1.5μm and a diameter of 10-50nm and put them into a plasma discharge device, introduce argon gas, discharge voltage at 60V, and discharge current at 0.25A. The time is 7min; 1g of plasma-modified carbon nanotubes is mixed with 50ml of deionized water in a three-necked flask and stirred evenly, and 12.12g of Fe(NO 3 ) 3 9H 2 O, 2.18g Co(NO 3 ) 2 ·6H 2 O, 2.18gNi(NO 3 ) 2 ·6H 2 O nitrate is added in the aqueous solution of carbon nanotubes, and then the experimental method is the same as that of Example 1 to obtain the modified carbon nanotubes / Co 0.5 Ni 0.5 Fe 2 o 4 Composite powder; 2g modified carbon nanotubes / Co 0.5 Ni 0.5 Fe 2 o 4 The ferrite composite powder was added in 42.5g dimethylacetamide (DMAc), and then the experimental method was the same as in Example 1 to finally obtain carbon nanotubes / Co 0.5 Ni 0.5 Fe 2 o 4 / Polyimide composite absorbing m...

Embodiment 3

[0028] At a temperature of 25°C, take 1g of multi-walled carbon nanotubes with an average length of 0.85-1.5μm and a diameter of 10-50nm and put them into a plasma discharge device, introduce argon gas, discharge voltage at 70V, and discharge current at 0.3A. The time is 10min; 1g of plasma-modified carbon nanotubes is mixed with 50ml of deionized water and stirred evenly, and 20.2g of Fe(NO 3 ) 3 9H 2 O, 3.63gCo(NO 3 ) 2 ·6H 2 O, 3.63gNi(NO 3 ) 2 ·6H 2 O nitrate is added in the aqueous solution of carbon nanotubes, and then the experimental method is the same as that of Example 1 to obtain the modified carbon nanotubes / Co 0.5 Ni 0.5 Fe 2 o 4 Composite powder; 3g modified carbon nanotubes / Co 05 Ni 05 Fe 2 o 4 The ferrite composite powder was added in 46.1g dimethylacetamide (DMAc), and then the experimental method was the same as in Example 1 to finally obtain carbon nanotubes / Co 05 Ni 05 Fe 2 o 4 / 10.93g of polyimide composite wave-absorbing material, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com