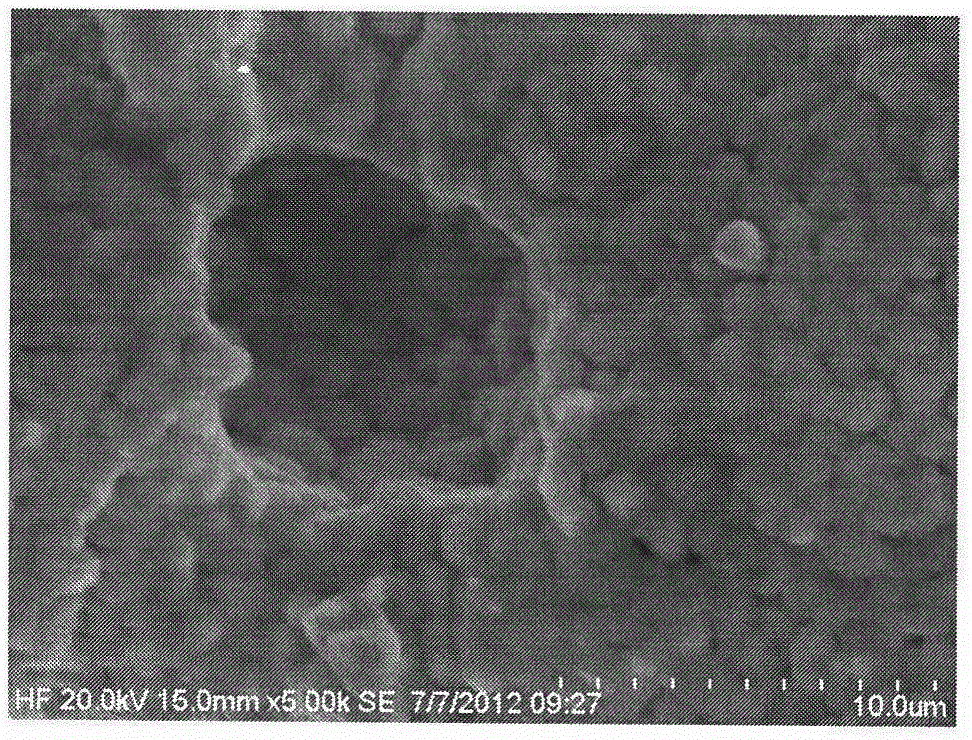

A kind of preparation method of superfine sno2 particle reinforced electric contact composite material

A particle-reinforced, composite material technology, used in contacts, circuits, electrical switches, etc., to solve problems such as affecting material properties, uneven distribution of traces, and poor wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] to prepare AgSnO 2 (15) Electric contact material as an example

[0037] In the first step, Ag ingots, Sn ingots and Cu ingots are melted and atomized to prepare AgSnCu powder, wherein the Ag content is 65%, the Sn content is 30%, and the Cu content is 5%.

[0038] In the second step, the atomized powder obtained in the first step is oxidized, and the parameters can be adopted: the oxidation temperature is 650° C., the oxygen pressure is 1.0 MPa, and the oxidation time is 60 hours.

[0039] In the third step, the oxidized powder is sieved to 400 mesh.

[0040] The fourth step is to refine and modify the surface of the sieved powder, wherein the pH of the silver-ammonia complex solution is 13, the concentration of Ag per liter is 80g / L, the stirring speed is 500r / min, and ultrasonic treatment , the ultrasonic frequency is 100kHz, and the power is 1000W.

[0041] The fifth step is to slowly spray the hydrazine hydrate solution using an atomizing device, wherein the con...

Embodiment 2

[0049] to prepare AgSnO 2 (10) Electric contact material as an example

[0050] In the first step, Ag ingots, Sn ingots and Zn ingots are melted and atomized to prepare AgSnZn powder, wherein the Ag content is 89%, the Sn content is 9%, and the Zn content is 2%.

[0051] In the second step, the atomized powder obtained in the first step is oxidized, wherein the oxidation temperature is 350° C., the oxygen pressure is 2 MPa, and the oxidation time is 15 hours.

[0052] The third step is to sieve the oxidized powder to 150 mesh.

[0053] The fourth step is to chemically coat the sieved powder, wherein the reaction solution adopts a silver-ammonia complex solution system, the solution pH=10, the concentration of Ag per liter is 40g / L, and the stirring speed is between 200r / min , and sonicate at a frequency of 70kHz and a power of 800W.

[0054] The fifth step is to slowly spray the hydrazine hydrate solution with an atomizing device, wherein the concentration of the hydrazine ...

Embodiment 3

[0062] to prepare AgSnO 2 (6) Electric contact material as an example

[0063] In the first step, Ag ingots, Sn ingots and CuZn ingots are smelted and atomized to prepare AgSnCuZn powder, wherein the Ag content is 93.5%, the Sn content is 6%, and the CuZn content is 0.5%.

[0064] In the second step, the atomized powder obtained in the first step is oxidized, wherein the oxidation temperature is between 650° C., the oxygen pressure is 1.0 MPa, and the oxidation time is 30 hours.

[0065] The third step is to sieve the oxidized powder to 300 mesh.

[0066] The fourth step is to chemically coat the sieved powder, the pH of the solution is 13, the concentration of Ag per liter is 10g / L, the stirring speed is 350r / min, and ultrasonic treatment is performed, and the ultrasonic frequency is 50kHz. The power is 500W.

[0067] The 5th step, slowly add the hydrazine hydrate solution dropwise, wherein the concentration of the hydrazine hydrate solution is 80wt%, and the dropping rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com