Zinc oxide-free microcrystalline

A technology of microcrystalline stone and zinc oxide, which is applied in the field of building materials, can solve the problems of increasing the production cost of enterprises, high production cost and high price of microcrystalline stone, and achieve the effects of improving production efficiency, convenient production, and meeting demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

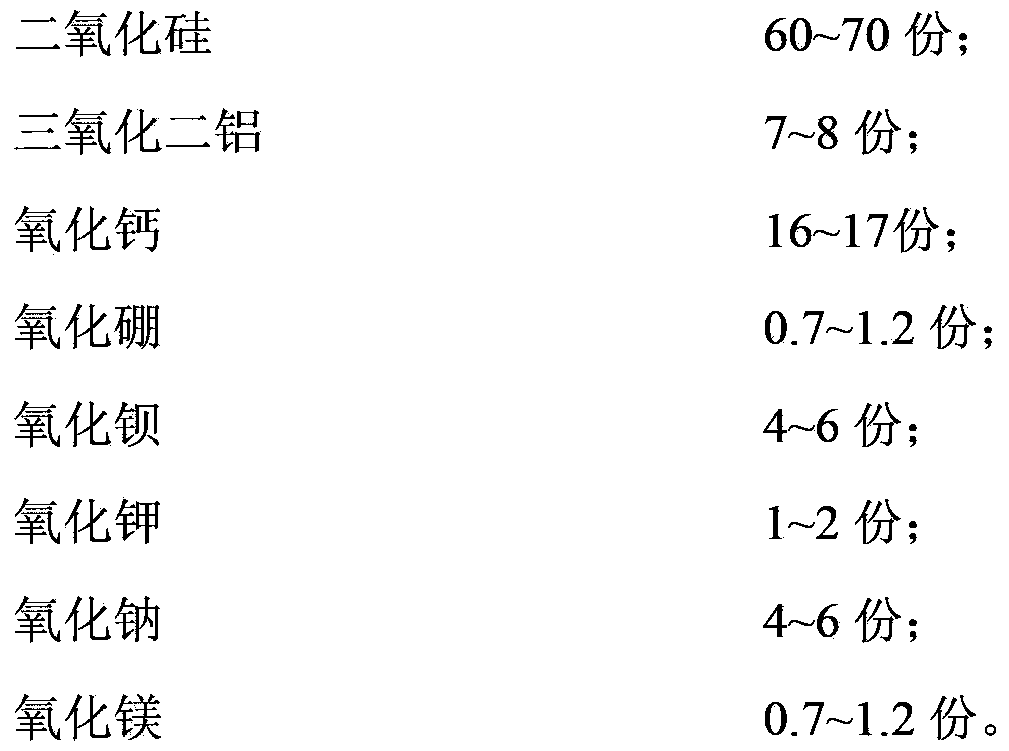

[0022] A zinc oxide-free microcrystalline stone, its composition and parts by weight are as follows:

[0023]

[0024] The preparation method of the above-mentioned zinc oxide-free microcrystalline stone, the steps are as follows:

[0025] After accurately weighing each raw material, the natural inorganic material is melted into glass liquid (magma) in a furnace up to 1600°C, quenched in water, and then crystallized at 1200°C to form microcrystalline stone (stone), and then ground and polished , cutting, deep processing, and inspection, the finished product of zinc oxide-free microcrystalline stone will be obtained.

Embodiment 2

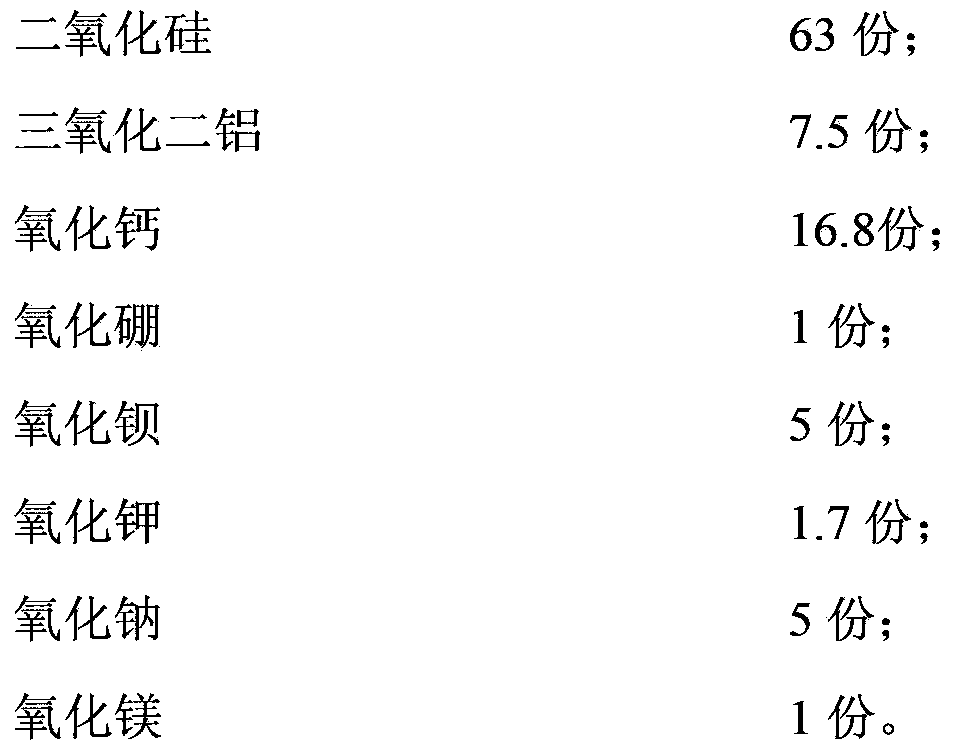

[0027] A zinc oxide-free microcrystalline stone, its composition and parts by weight are as follows:

[0028]

[0029]

[0030] The preparation method of the above-mentioned zinc oxide-free microcrystalline stone is the same as in Example 1.

Embodiment 3

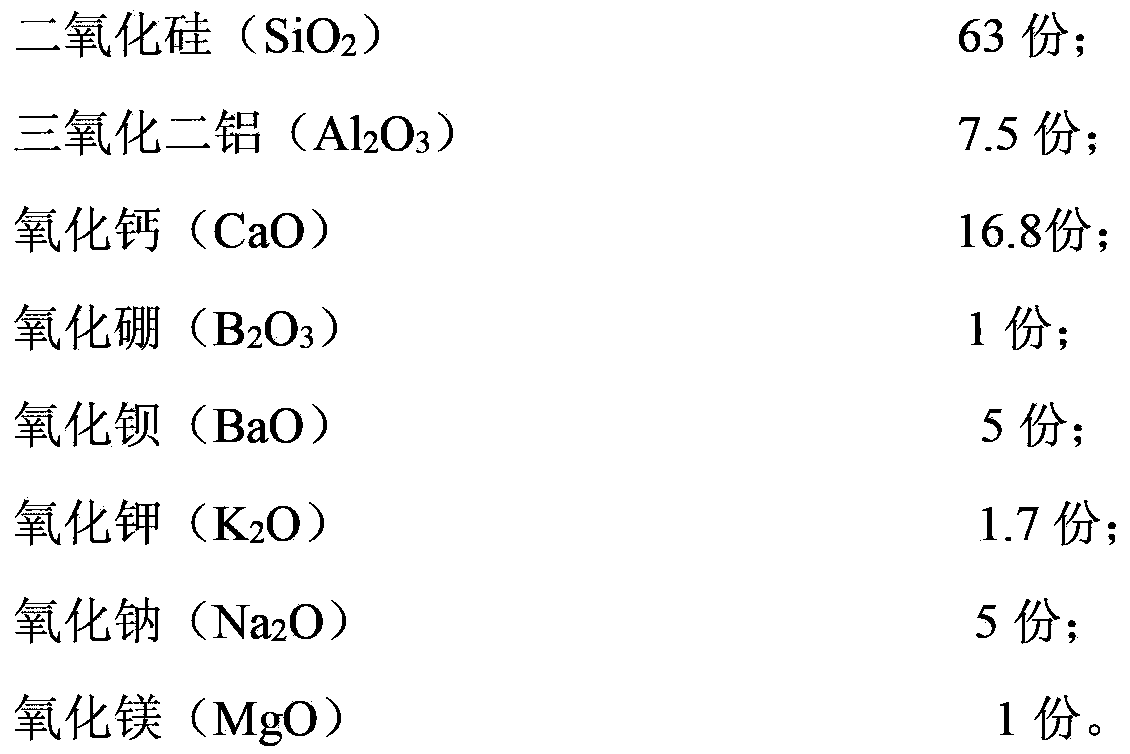

[0032] A zinc oxide-free microcrystalline stone, its composition and parts by weight are as follows:

[0033]

[0034] The preparation method of the above-mentioned zinc oxide-free microcrystalline stone is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com