Hydrophobic, scratch-resistant and light-resistant UV-LED curing oil polish for paper packaging printed matters

A UV-LED, printed matter technology, used in coatings, epoxy resin coatings, polyester coatings, etc., can solve the problems of low curing degree, weak absorption, and low photoinitiator initiation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The formula of UV-LED curable varnish is expressed as (Wt%) with mass percentage:

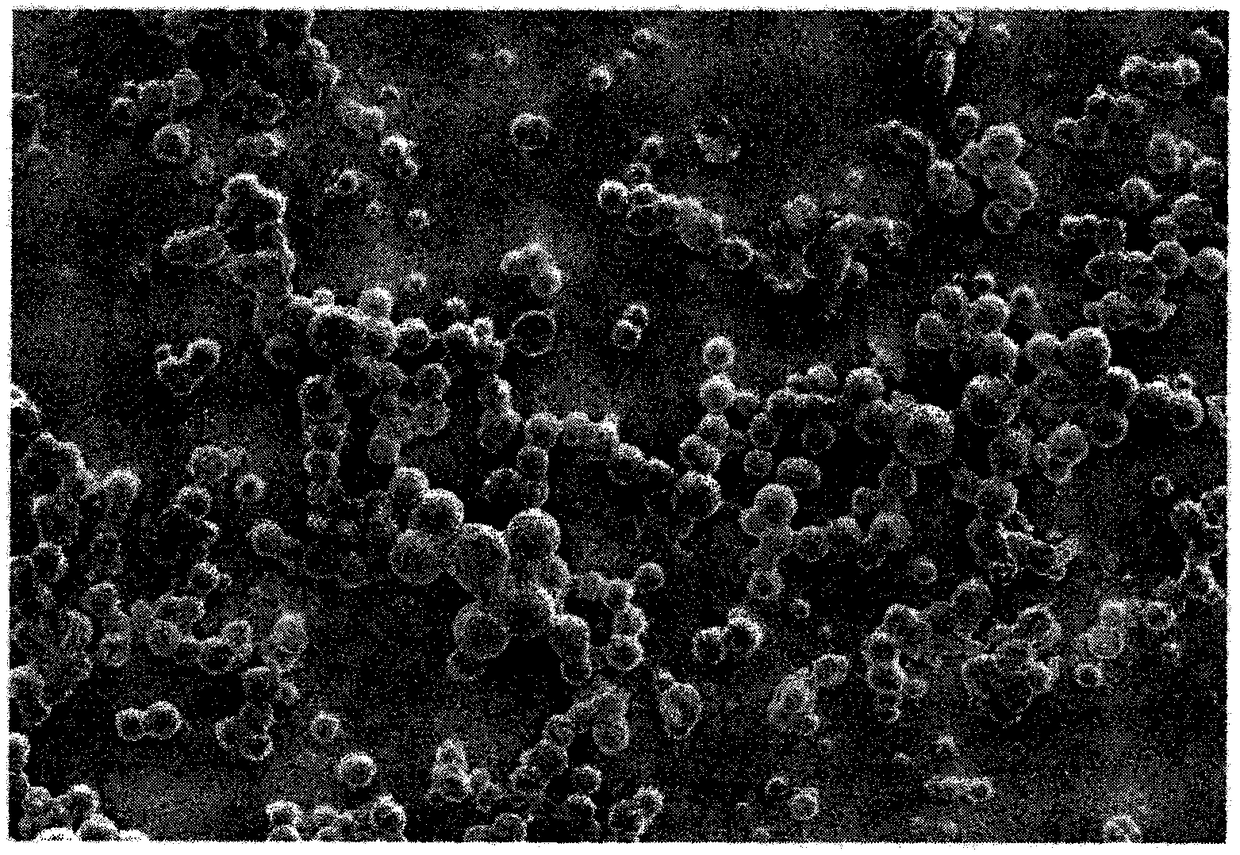

[0048] In the first step, the synthesized nano-Al with D50 diameter of 40nm 2 o 3 A thin layer of transparent SiOx (x=0.3-2) is formed by plasma polymerization.

[0049] In a closed glass container, the powder moves under the action of mechanical stirring, and a plasma discharge system is formed in the closed space with a power supply with a frequency of 13.56MHz and a maximum power of 1000W. When the vacuum reaches about 20Pa, Ar Hexamethyldisiloxane, the reactive monomer of the carrier gas, forms transparent SiO with a thickness of several angstroms on the surface of the powder x (x=0.3-2) film to improve the dispersion performance of the powder in the active monomer.

[0050] In the second step, the surface-modified nano-Al 2 o 3 Uniformly dispersed in tripropylene glycol diacrylate (TPGDA) reactive monomer. Under the condition of not adding wetting and dispersing agent, add the...

Embodiment 2

[0064] The formula of UV-LED curable varnish is expressed as (Wt%) with mass percentage:

[0065] In the first step, the synthesized nano-ZrO with D50 diameter of 40nm 2 Forming a layer of transparent SiO using plasma polymerization x TLC.

[0066] In a closed glass container, the powder moves under the action of mechanical stirring, and a plasma discharge system is formed in the closed space with a power supply with a frequency of 13.56MHz and a maximum power of 1000W. When the vacuum reaches about 20Pa, Ar The reactive monomer dimethyldisiloxane, which is the carrier gas, forms transparent SiO with a thickness of about several angstroms on the surface of the powder x (x 0.3-2) film to improve the dispersion performance of powder in active monomer.

[0067] In the second step, the surface-modified nano-ZrO 2 Uniformly dispersed in trifunctional trimethylolpropane triacrylate (TMPTA) reactive monomer. Under the condition of not adding wetting and dispersing agent, add the...

Embodiment 3

[0081] In the first step, the synthesized nano-SiO with D50 diameter of 20nm 2 Forming a layer of transparent SiO using plasma polymerization x TLC.

[0082] In a closed glass container, the powder moves under the action of mechanical stirring, and a plasma discharge system is formed in the closed space with a power supply with a frequency of 13.56MHz and a maximum power of 1000W. When the vacuum reaches about 20Pa, Ar The reactive monomer tetramethyldisiloxane, which is the carrier gas, forms transparent SiO with a thickness of about several angstroms on the surface of the powder x (x 0.3-2) film to improve the dispersion performance of powder in active monomer.

[0083] In the second step, the surface-modified nano-SiO 2 Uniformly dispersed in N-acryloylmorpholine (acmo) active monomer. Under the condition of not adding wetting and dispersing agent, add the powder to the active monomer, disperse at high speed, and then sand with a sand mill. The sand mill uses zirconia b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com