Water-repellent and oil-proof treatment method and device for filter cloth

A water- and oil-repellent, treatment device technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of low production efficiency of the dipping method, affecting the use of filter cloth, discoloration of filter cloth, etc., to improve water and oil repellency. The effect of treatment efficiency, reduction of water consumption, and reduction of waste water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

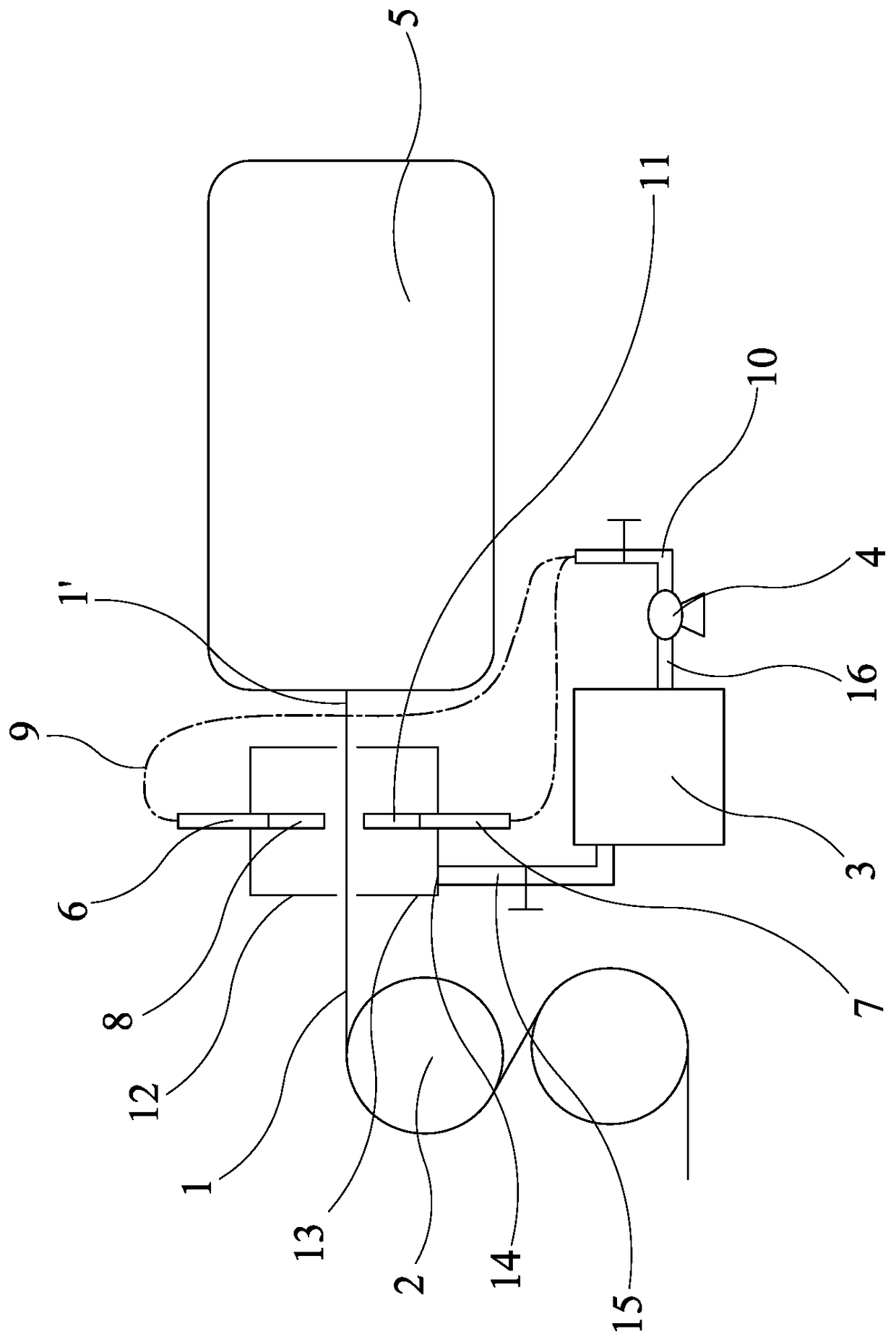

[0023] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

[0024] A water-repellent and oil-repellent treatment method for filter cloth, comprising the following steps:

[0025] Step 1: Configure water-repellent and oil-repellent liquid; configure water-repellent and oil-repellent liquid according to the mass concentration of fluorine-containing water-repellent and oil-repellent agent of 5-10%, the mass concentration of cross-linking agent of 0.5-2%, and the mass concentration of water of 90%-95%.

[0026] Step 2. Pressurize and atomize the above-mentioned water-repellent and oil-repellent liquid and evenly spray it on the upper and lower surfaces of the filter cloth 1;

[0027] Step 3: drying the filter cloth 1' sprayed with the water and oil repellent liquid to obtain a finished product; the drying temperature is 160-180°C.

[0028] Spray the water-repellent and oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com