Chlorine-free durable waterproof and oil-proof agent and preparation method thereof

A waterproof and oil-repellent agent, waterproof and oil-repellent technology, applied in the direction of textiles and papermaking, fiber treatment, plant fiber, etc., can solve the problem of limiting the use of cross-linking monomers, great influence on water and oil repellency, and affecting water and oil repellency and other issues, to achieve the effect of being beneficial to environmental protection, improving waterproof and oil-proof performance, and enhancing the effect of water and oil repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Fluorine-containing polymers and fluorine-free polymers were respectively prepared by conventional free radical emulsion polymerization process according to the following proportions.

[0048]

[0049] 1. The specific preparation method of water and oil repellent is as follows:

[0050] (1) Stir and insulate the ingredients except the initiator at 60°C for 30 minutes, high-speed shear for 5 minutes, and homogenize;

[0051] (2) feed liquid is poured into reaction bottle, logical nitrogen N 2 , the temperature dropped to 55°C, and the nitrogen gas was turned off;

[0052] (3) The initiator is diluted with 10 times of water, and the initiator is added dropwise when the temperature in the reaction bottle rises to 62°C;

[0053] (4) 15 minutes after the initiator was added dropwise, the temperature rise reaction began, and the temperature rose to 68-69°C and began to fall. After 20 minutes, the initiator was dripped and kept warm to 62-65°C. Continue to react until the...

Embodiment 2

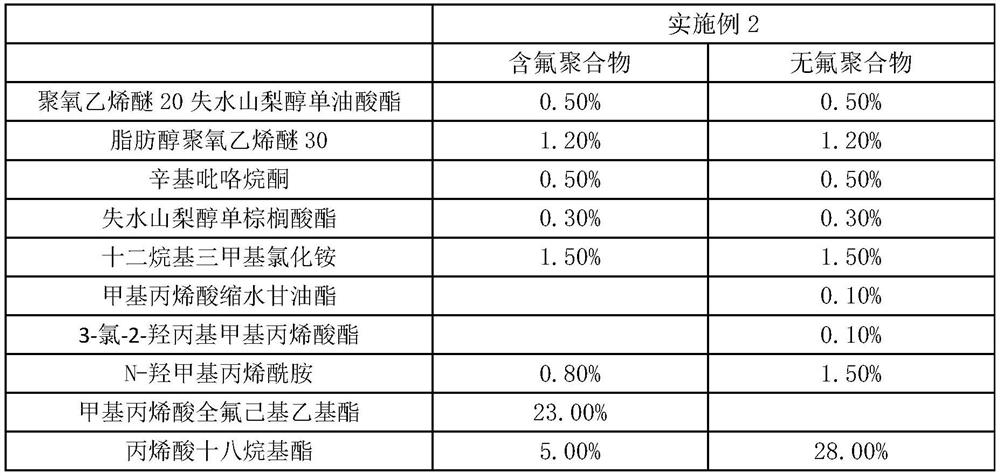

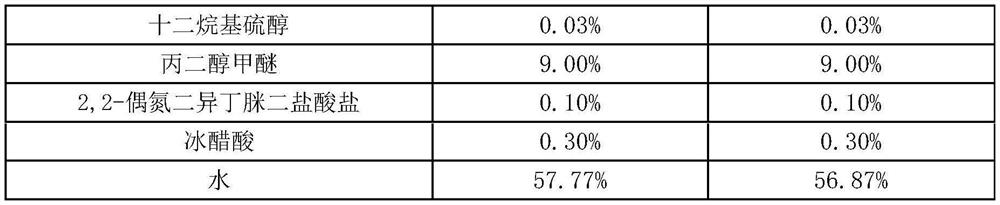

[0060] Fluorine-containing polymers and fluorine-free polymers were respectively prepared by conventional free radical emulsion polymerization process according to the following proportions.

[0061]

[0062]

[0063] The specific preparation method of the water and oil repellent is the same as in Example 1.

[0064] According to the mass ratio of 1:1, the fluorine-containing polymer and the fluorine-free polymer are evenly mixed.

[0065] The waterproof and oil-repellent finishing method of fabric is identical with embodiment 1.

Embodiment 3

[0067] Fluorine-containing polymers and fluorine-free polymers were respectively prepared by conventional free radical emulsion polymerization process according to the following proportions.

[0068]

[0069] The specific preparation method of the water and oil repellent is the same as in Example 1.

[0070] According to the mass ratio of 1:1, the fluorine-containing polymer and the fluorine-free polymer are evenly mixed.

[0071] The waterproof and oil-repellent finishing method of fabric is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com