Water-based wax oil composition and preparation method thereof

A technology for wood wax oil and composition, which is applied in the field of water-based wood wax oil composition and its preparation, and can solve the problems of poor abrasion resistance and aging resistance of coating films and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

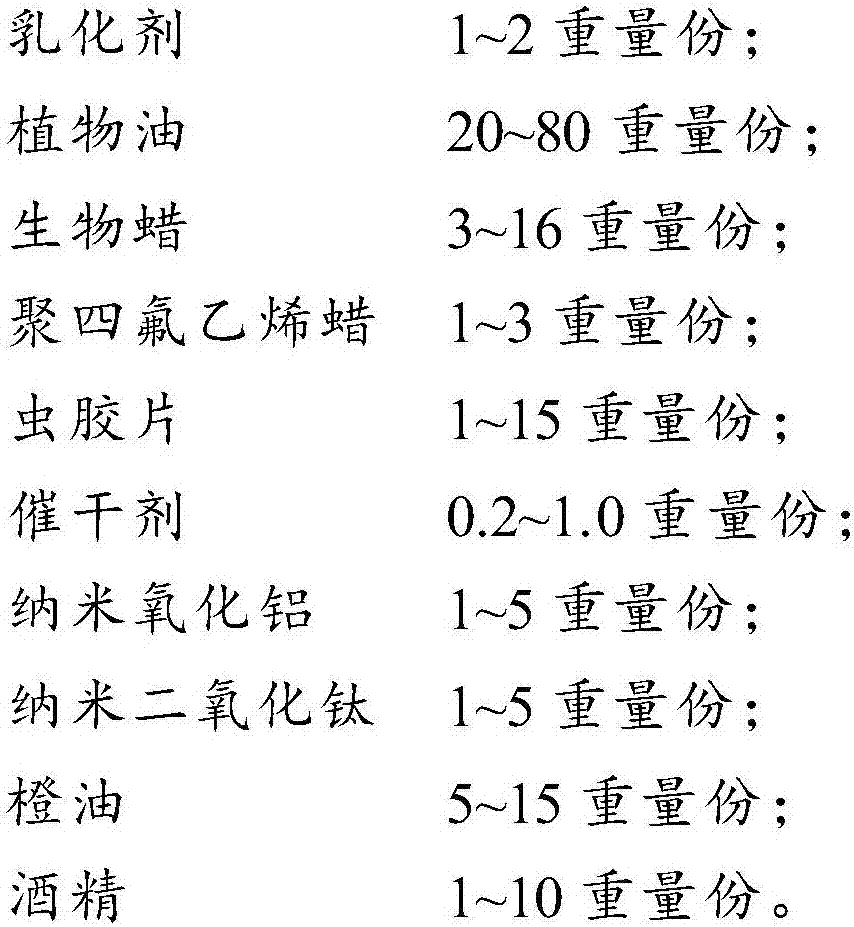

[0033] The application also provides the preparation method of described aqueous wood wax oil composition, comprises the following steps:

[0034] Mixing 5-15 parts by weight of orange oil, 1-10 parts by weight of alcohol, 5-20 parts by weight of water and 1-15 parts by weight of shellac flakes to obtain the first mixture;

[0035] Mixing the first part by weight of vegetable oil, 1-5 parts by weight of nano-alumina, 1-5 parts by weight of nano-titanium dioxide and 1-3 parts by weight of polytetrafluoroethylene wax to obtain a second mixture;

[0036] Heat and melt 3-16 parts of biological wax and mix it with the second part of vegetable oil, then add the second mixture and 1-2 parts of emulsifier, then add 0.2-1.0 parts by weight of the first mixture to cool down A drier to obtain a water-based paraffin oil mixture; the total mass parts of the first weight part of vegetable oil and the second weight part of vegetable oil is 20-80 parts by weight.

[0037] In the above proces...

Embodiment 1

[0045]

[0046] Get 5.4 parts by weight of orange oil, 5 parts by weight of ethanol, 5 parts by weight of water, and 2.5 parts by weight of shellac, and mix them uniformly to obtain mixture A;

[0047] Take 25 parts by weight of tung oil and add it to 5 parts by weight of nano-alumina, 5 parts by weight of nano-titanium dioxide and 3 parts by weight of polytetrafluoroethylene wax emulsion, and disperse at a high speed to obtain mixture B;

[0048] Take 10 parts by weight of tung oil and 23 parts by weight of linseed oil and mix to obtain mixture C;

[0049] Mix 5 parts by weight of carnauba wax and 4.3 parts by weight of beeswax, heat it at 180°C until it melts, add it dropwise to the above mixture C, stir and mix evenly at a high speed, then keep it at 180°C, add mixture B to disperse for 10min, keep the above temperature and add emulsifier (fatty amide poly Oxyethylene ether) 1 weight part, stir evenly, add mixture A dropwise, after stirring evenly, lower the temperature ...

Embodiment 2

[0051]

[0052] Get 9 parts by weight of orange oil, 10 parts by weight of ethanol, 10 parts by weight of deionized water, and 10 parts by weight of shellac, and mix them uniformly to obtain mixture A;

[0053] Take 12 parts by weight of sunflower oil, add 4 parts by weight of nano-alumina, 2 parts by weight of nano-titanium dioxide, and 3 parts by weight of polytetrafluoroethylene wax emulsion, and disperse at a high speed to obtain mixture B;

[0054] Mix 7.7 parts by weight of tung oil and 10 parts by weight of linseed oil to obtain mixture C, mix 5 parts by weight of carnauba wax, 3 parts by weight of candelilla wax, and 7.5 parts by weight of beeswax, heat it to 180°C until it melts, and add it dropwise to the above mixture C Stir at high speed and mix evenly, keep at 180°C, add mixture B to disperse for 10 minutes, keep the above temperature, add emulsifier (polyoxyethylene lauryl ether) 2 parts by weight, stir evenly, add mixture A dropwise, stir evenly, lower the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com